Page 26: of Marine News Magazine (September 2025)

Read this page in Pdf, Flash or Html5 edition of September 2025 Marine News Magazine

Feature

Ship Repair

The Challenges required far exceeded what MES alone could provide. The so-

The ? rst major obstacle came quickly: supply chain lead lution was an innovative blend of resources: MES engineers, times. Some critical components carried manufacturer Dutra’s own shoreside electricians ? own in from California, estimates of six months or longer, an unacceptable delay the Stuyvesant’s crew, and local subcontractors all pitched in.

given the tight project window. MES had to leverage its “Everyone had to stretch,” Smith says. “Dutra’s electri- supplier relationships, explore alternate vendors, and, in cians, who were used to working on big crane systems, some cases, engineer custom solutions to stay on schedule. suddenly found themselves working on PLCs and sensors.

Once equipment was secured, the next hurdle was They learned on the ? y and did a fantastic job. Our team, manpower. too … if someone needed to pull cable, hang lights, or pitch

The amount of cabling, integration, and commissioning in on cleanup, we just rolled up our sleeves.” [Devin Smith

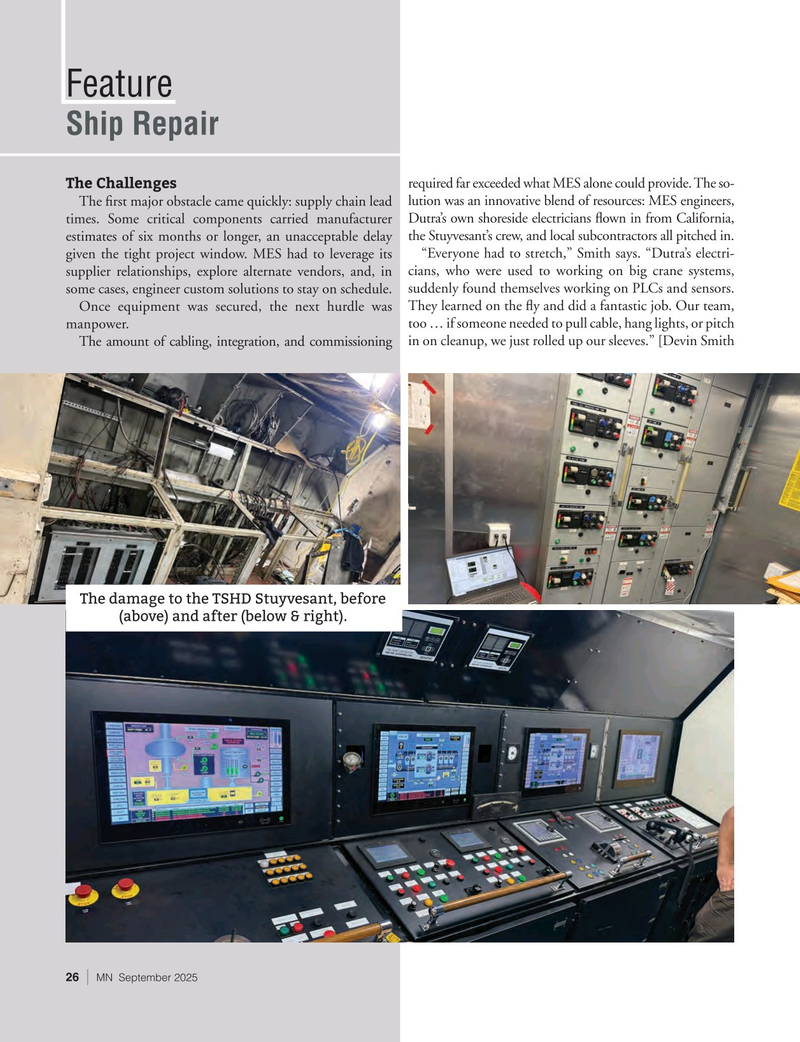

The damage to the TSHD Stuyvesant, before (above) and after (below & right).

26 | MN September 2025

25

25

27

27