Page 30: of Marine News Magazine (September 2025)

Read this page in Pdf, Flash or Html5 edition of September 2025 Marine News Magazine

Feature

Ship Repair

It is no different in global shipbuilding. The foreign $6.2B and the RRF yards produce their own designs and with that easily fol- The Secretary of Transportation has given us the op- low through with production and they understand their portunity to support and rebuild our repair capacity and own standards. The U.S. yards rely on designs provided $6.2 billion US dollars has been provided to make it by outside sources and in our antiquated competitive pro- work if it is done correctly within the MarAd RRF pro- cess, your guess is as good as mine and who will eventually gram. Yes, $6.2 billion U.S. dollars within a program of build. The Far East yards employ their own naval archi- vessels that are idle and wait orders to serve.

tects – hundreds. And with that the risk of “change order” The average age of the RRF ? eet is ? fty-one (51) years. or delivery delays are mitigated. It is a proven design. The last true “activation” was Desert Fox, Desert Storm

Make no mistake about it, with the cost of new construc- and Desert Freedom. The after-action reports describing tion in the United States, our repair capability to complete the failures of the program from both activation and oper- replacement of outdated machinery, large steel renewals and ation resulted in additional foreign tonnage being ? agged upgraded coatings will work to achieve existing tonnage life in. “Reserve Operating Status” was developed where select- extension periods well beyond the vessel’s next drydock. ed tonnage was made available with a reduced operating

This is the transition period needed during the next decade crew, at selected berths with developed maintenance pro- to rebuild our shipyard capacity for new construction. cedures to make them available between 48 and 76 hours.

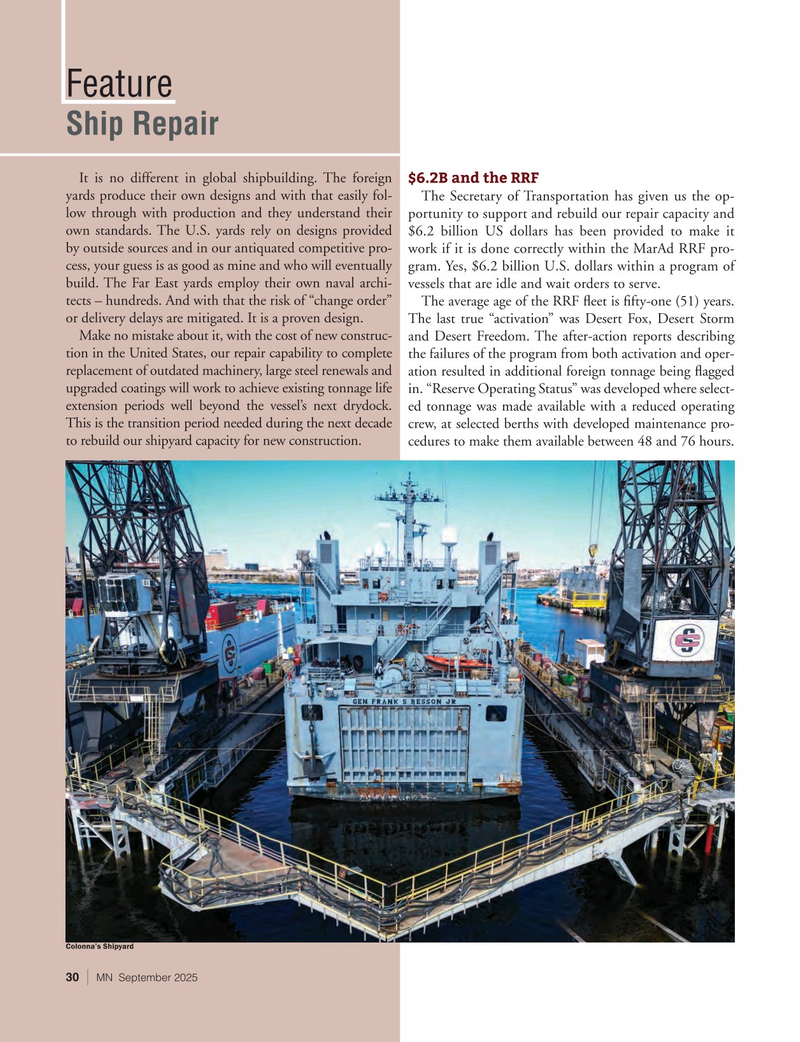

Colonna’s Shipyard 30 | MN September 2025

29

29

31

31