Page 49: of Offshore Engineer Magazine (Feb/Mar 2013)

Read this page in Pdf, Flash or Html5 edition of Feb/Mar 2013 Offshore Engineer Magazine

Drilling & Completions allows unforeseen problems with Weatherford was selected to of the tubulars. The operator also tubular management and running to provide management services that calculated that a saving of $400,000 be addressed quickly and correctly included mobilizing a bucking unit was achieved by preparing the prior to wellsite installation. equipped with torque/turn process pipe offsite, and eliminated the control systems to the operator’s need for offshore pipe cleaning and

Australian developments onshore support base to make transportation costs associated with 5 8 1 2

Resultant improvements in doubles of 9/in, 7in and 4/in wastewater disposal. rig effciency using tubular PH6 tubulars. The operator also This same operator installed management services have been required full pipe preparation and a top loading Hydraulic Mobile documented in many locations, yard management services (Figure 2). Bucking Unit (HMBU) on board the both on- and offshore. But given In compliance with these requests, same rig for use in make-up and the high costs and risks associated the tubulars were cleaned, break-out of sub-assemblies such with handling and deploying pipe inspected and drifted; the threads as hole openers, running tools and for offshore wells, the most interest were cleaned and doped; the jetting tools for a separate six-well has come from offshore operators. tubulars were bucked into doubles, program. The HMBU recorded

This is certainly the case in laser tallied and tagged; thread and stored the connection torque

Australia, where continued offshore protectors were re-installed; and for the BHA, which improved

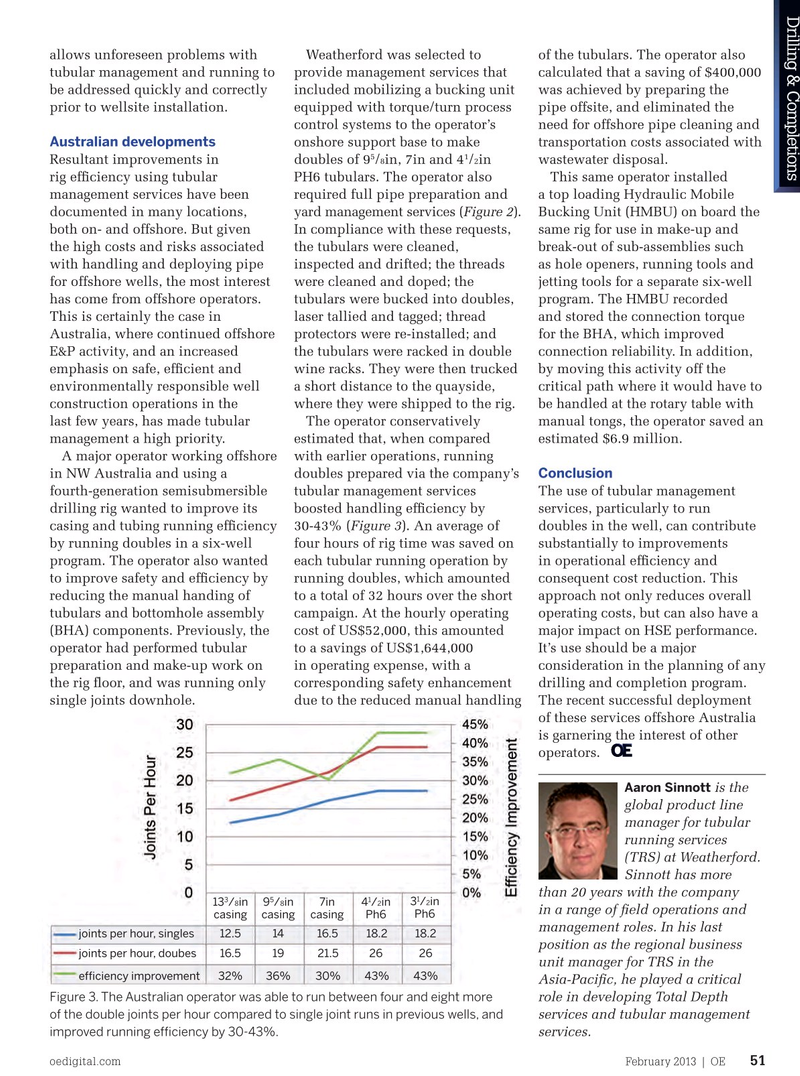

E&P activity, and an increased the tubulars were racked in double connection reliability. In addition, emphasis on safe, effcient and wine racks. They were then trucked by moving this activity off the environmentally responsible well a short distance to the quayside, critical path where it would have to construction operations in the where they were shipped to the rig. be handled at the rotary table with last few years, has made tubular The operator conservatively manual tongs, the operator saved an management a high priority. estimated that, when compared estimated $6.9 million. A major operator working offshore with earlier operations, running in NW Australia and using a doubles prepared via the company’s Conclusion fourth-generation semisubmersible tubular management services The use of tubular management drilling rig wanted to improve its boosted handling effciency by services, particularly to run casing and tubing running effciency 30-43% (Figure 3). An average of doubles in the well, can contribute by running doubles in a six-well four hours of rig time was saved on substantially to improvements program. The operator also wanted each tubular running operation by in operational effciency and to improve safety and effciency by running doubles, which amounted consequent cost reduction. This reducing the manual handing of to a total of 32 hours over the short approach not only reduces overall tubulars and bottomhole assembly campaign. At the hourly operating operating costs, but can also have a (BHA) components. Previously, the cost of US$52,000, this amounted major impact on HSE performance.

operator had performed tubular to a savings of US$1,644,000 It’s use should be a major preparation and make-up work on in operating expense, with a consideration in the planning of any the rig foor, and was running only corresponding safety enhancement drilling and completion program. single joints downhole. due to the reduced manual handling The recent successful deployment of these services offshore Australia is garnering the interest of other operators. is the

Aaron Sinnott global product line manager for tubular running services (TRS) at Weatherford.

Sinnott has more than 20 years with the company 3 5 1 1 13/in 9/in 7in 4/in 3/in 8 8 2 2 in a range of feld operations and casing casing casing Ph6 Ph6 management roles. In his last joints per hour, singles 12.51416.518.218.2 position as the regional business 16.5 19 21.5 26 joints per hour, doubes 26 unit manager for TRS in the effciency improvement 32%36%30%43%43%

Asia-Pacifc, he played a critical role in developing Total Depth

Figure 3. The Australian operator was able to run between four and eight more services and tubular management of the double joints per hour compared to single joint runs in previous wells, and services. improved running effciency by 30-43%.

oedigital.com February 2013 | OE 51 oe_D&C.indd 51 31/01/2013 10:50

48

48

50

50