Page 36: of Offshore Engineer Magazine (Apr/May 2013)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2013 Offshore Engineer Magazine

jackup drilling rigs, there might be supporting services and materials. try a consistent view of all asset 100,000 different parts or objects in EAM that is truly optimized for the information – one version of the that asset environment. You might offshore industry will take this into truth – insuring policies, plans, and have 50,000 different spare parts consideration and offer integrated actions, are based on an accurate in your inventory and all of these contract management. Cash outlays understanding of the history and

Eyebrow are named in a very localized way. necessary under each contract current status of asset infrastruc-

That is because the part-naming will be planned as the contract is ture. In order to accomplish this, an

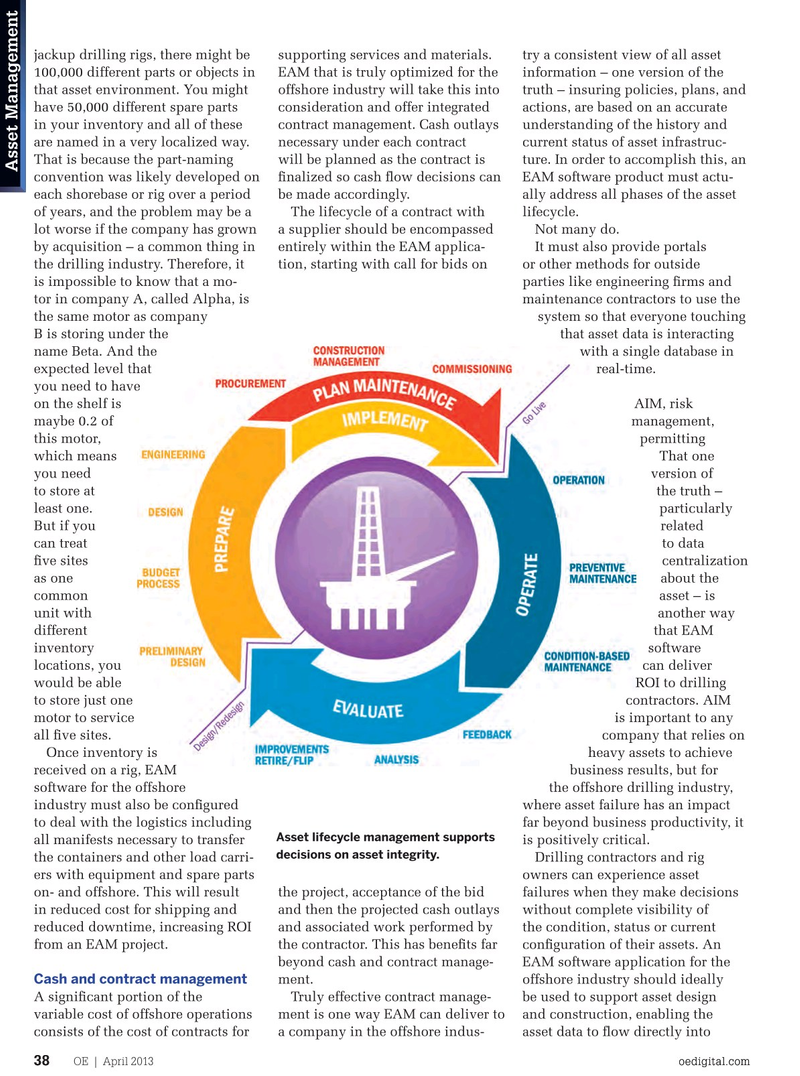

Asset Management convention was likely developed on fnalized so cash fow decisions can EAM software product must actu- each shorebase or rig over a period be made accordingly. ally address all phases of the asset of years, and the problem may be a The lifecycle of a contract with lifecycle. lot worse if the company has grown a supplier should be encompassed Not many do. by acquisition – a common thing in entirely within the EAM applica- It must also provide portals the drilling industry. Therefore, it tion, starting with call for bids on or other methods for outside is impossible to know that a mo- parties like engineering frms and tor in company A, called Alpha, is maintenance contractors to use the the same motor as company system so that everyone touching

B is storing under the that asset data is interacting name Beta. And the with a single database in expected level that real-time. you need to have on the shelf is AIM, risk maybe 0.2 of management, this motor, permitting which means That one you need version of to store at the truth – least one. particularly

But if you related can treat to data fve sites centralization as one about the common asset – is unit with another way different that EAM inventory software locations, you can deliver would be able ROI to drilling to store just one contractors. AIM motor to service is important to any all fve sites. company that relies on

Once inventory is heavy assets to achieve received on a rig, EAM business results, but for software for the offshore the offshore drilling industry, industry must also be confgured where asset failure has an impact to deal with the logistics including far beyond business productivity, it

Asset lifecycle management supports all manifests necessary to transfer is positively critical.

decisions on asset integrity.

the containers and other load carri- Drilling contractors and rig ers with equipment and spare parts owners can experience asset the project, acceptance of the bid on- and offshore. This will result failures when they make decisions and then the projected cash outlays in reduced cost for shipping and without complete visibility of and associated work performed by reduced downtime, increasing ROI the condition, status or current the contractor. This has benefts far from an EAM project. confguration of their assets. An beyond cash and contract manage- EAM software application for the ment. Cash and contract management offshore industry should ideally

Truly effective contract manage- A signifcant portion of the be used to support asset design ment is one way EAM can deliver to variable cost of offshore operations and construction, enabling the a company in the offshore indus- consists of the cost of contracts for asset data to fow directly into

OE | April 2013 oedigital.comoedigital.com 3838 oe_rigassetmgmt.indd 38 4/1/13 2:47 AM

35

35

37

37