Page 45: of Offshore Engineer Magazine (Apr/May 2013)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2013 Offshore Engineer Magazine

Drilling

Eyebrow

Rigless drilling enters the pilot stage

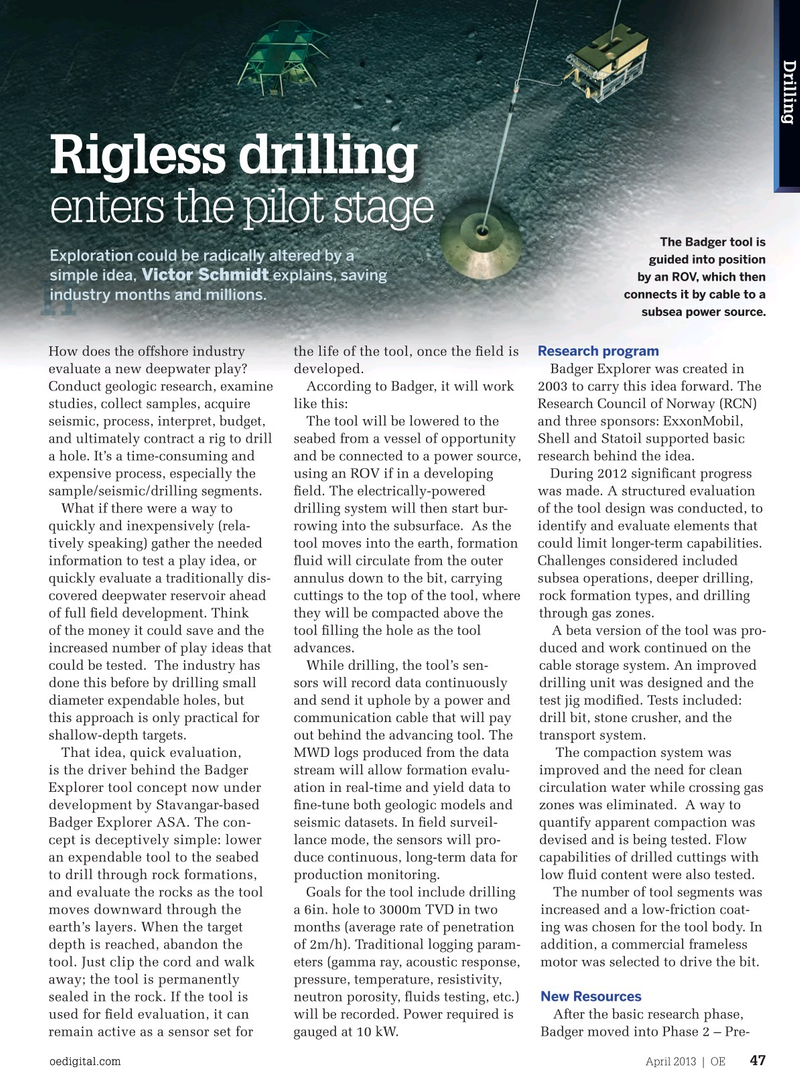

The Badger tool is

Exploration could be radically altered by a guided into position

Victor Schmidt simple idea, explains, saving by an ROV, which then connects it by cable to a industry months and millions.

H subsea power source.

How does the offshore industry the life of the tool, once the feld is Research program evaluate a new deepwater play? developed. Badger Explorer was created in

Conduct geologic research, examine According to Badger, it will work 2003 to carry this idea forward. The studies, collect samples, acquire like this: Research Council of Norway (RCN) seismic, process, interpret, budget, The tool will be lowered to the and three sponsors: ExxonMobil, and ultimately contract a rig to drill seabed from a vessel of opportunity Shell and Statoil supported basic a hole. It’s a time-consuming and and be connected to a power source, research behind the idea. expensive process, especially the using an ROV if in a developing During 2012 signifcant progress sample/seismic/drilling segments. feld. The electrically-powered was made. A structured evaluation

What if there were a way to drilling system will then start bur- of the tool design was conducted, to quickly and inexpensively (rela- rowing into the subsurface. As the identify and evaluate elements that tively speaking) gather the needed tool moves into the earth, formation could limit longer-term capabilities. information to test a play idea, or fuid will circulate from the outer Challenges considered included quickly evaluate a traditionally dis- annulus down to the bit, carrying subsea operations, deeper drilling, covered deepwater reservoir ahead cuttings to the top of the tool, where rock formation types, and drilling of full feld development. Think they will be compacted above the through gas zones. of the money it could save and the tool flling the hole as the tool A beta version of the tool was pro- increased number of play ideas that advances. duced and work continued on the could be tested. The industry has While drilling, the tool’s sen- cable storage system. An improved done this before by drilling small sors will record data continuously drilling unit was designed and the diameter expendable holes, but and send it uphole by a power and test jig modifed. Tests included: this approach is only practical for communication cable that will pay drill bit, stone crusher, and the shallow-depth targets. out behind the advancing tool. The transport system.

That idea, quick evaluation, MWD logs produced from the data The compaction system was is the driver behind the Badger stream will allow formation evalu- improved and the need for clean

Explorer tool concept now under ation in real-time and yield data to circulation water while crossing gas development by Stavangar-based fne-tune both geologic models and zones was eliminated. A way to

Badger Explorer ASA. The con- seismic datasets. In feld surveil- quantify apparent compaction was cept is deceptively simple: lower lance mode, the sensors will pro- devised and is being tested. Flow an expendable tool to the seabed duce continuous, long-term data for capabilities of drilled cuttings with to drill through rock formations, production monitoring. low fuid content were also tested.

and evaluate the rocks as the tool Goals for the tool include drilling The number of tool segments was moves downward through the a 6in. hole to 3000m TVD in two increased and a low-friction coat- earth’s layers. When the target months (average rate of penetration ing was chosen for the tool body. In depth is reached, abandon the of 2m/h). Traditional logging param- addition, a commercial frameless tool. Just clip the cord and walk eters (gamma ray, acoustic response, motor was selected to drive the bit.

away; the tool is permanently pressure, temperature, resistivity, sealed in the rock. If the tool is neutron porosity, fuids testing, etc.) New Resources used for feld evaluation, it can will be recorded. Power required is After the basic research phase, remain active as a sensor set for gauged at 10 kW. Badger moved into Phase 2 – Pre- oedigital.com oedigital.com April 2013 | OE 47 d_c1_badger.indd 47 4/2/13 8:53 AM

44

44

46

46