Page 49: of Offshore Engineer Magazine (Apr/May 2013)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2013 Offshore Engineer Magazine

and standing 77.4m high, was the highest-strength mooring sys-

Eyebrow

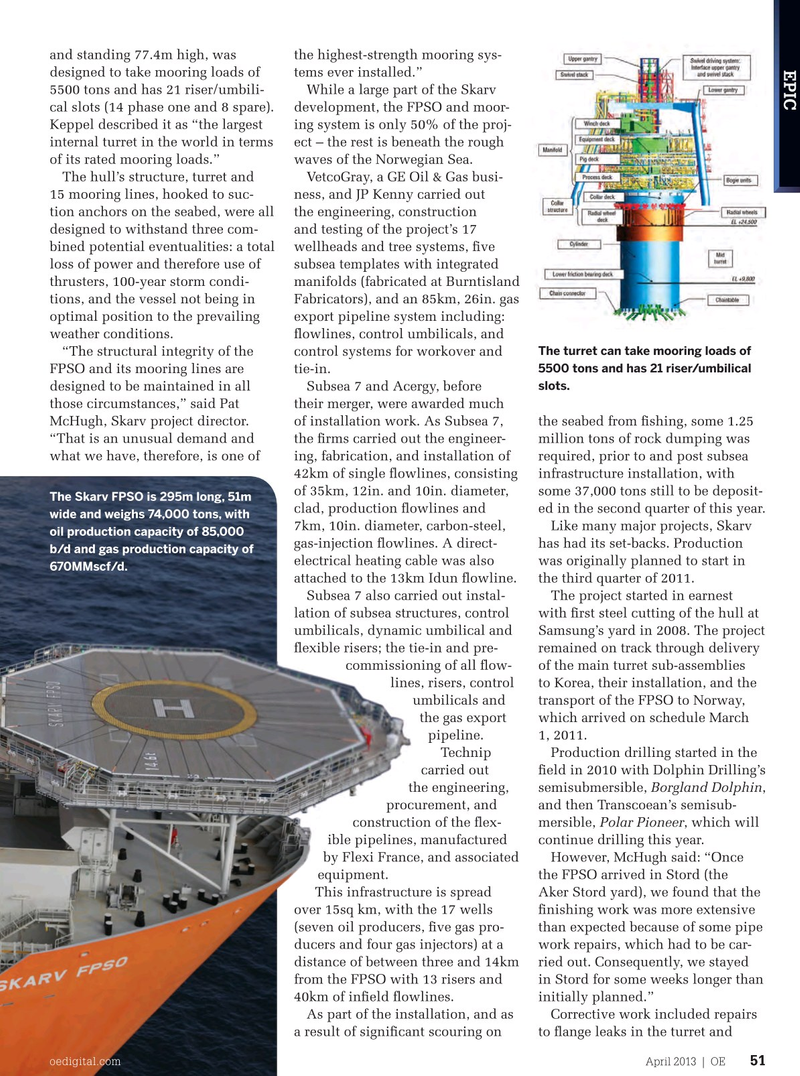

EPIC designed to take mooring loads of tems ever installed.” 5500 tons and has 21 riser/umbili- While a large part of the Skarv cal slots (14 phase one and 8 spare). development, the FPSO and moor-

Keppel described it as “the largest ing system is only 50% of the proj- internal turret in the world in terms ect – the rest is beneath the rough of its rated mooring loads.” waves of the Norwegian Sea.

The hull’s structure, turret and VetcoGray, a GE Oil & Gas busi- 15 mooring lines, hooked to suc- ness, and JP Kenny carried out tion anchors on the seabed, were all the engineering, construction designed to withstand three com- and testing of the project’s 17 bined potential eventualities: a total wellheads and tree systems, fve loss of power and therefore use of subsea templates with integrated thrusters, 100-year storm condi- manifolds (fabricated at Burntisland tions, and the vessel not being in Fabricators), and an 85km, 26in. gas optimal position to the prevailing export pipeline system including: weather conditions. fowlines, control umbilicals, and

The turret can take mooring loads of “The structural integrity of the control systems for workover and 5500 tons and has 21 riser/umbili cal

FPSO and its mooring lines are tie-in.

slots. designed to be maintained in all Subsea 7 and Acergy, before those circumstances,” said Pat their merger, were awarded much

McHugh, Skarv project director. of installation work. As Subsea 7, the seabed from fshing, some 1.25 “That is an unusual demand and the frms carried out the engineer- million tons of rock dumping was what we have, therefore, is one of ing, fabrication, and installation of required, prior to and post subsea 42km of single fowlines, consisting infrastructure installation, with of 35km, 12in. and 10in. diameter, some 37,000 tons still to be deposit-

The Skarv FPSO is 295m long, 51m clad, production fowlines and ed in the second quarter of this year. wide and weighs 74,000 tons, with 7km, 10in. diameter, carbon-steel, Like many major projects, Skarv oil production capacity of 85,000 gas-injection fowlines. A direct- has had its set-backs. Production b/d and gas production capacity of electrical heating cable was also was originally planned to start in 670MMscf/d. attached to the 13km Idun fowline. the third quarter of 2011.

Subsea 7 also carried out instal- The project started in earnest lation of subsea structures, control with frst steel cutting of the hull at umbilicals, dynamic umbilical and Samsung’s yard in 2008. The project fexible risers; the tie-in and pre- remained on track through delivery commissioning of all fow- of the main turret sub-assemblies lines, risers, control to Korea, their installation, and the umbilicals and transport of the FPSO to Norway, the gas export which arrived on schedule March pipeline. 1, 2011.

Technip Production drilling started in the carried out feld in 2010 with Dolphin Drilling’s the engineering, semisubmersible, Borgland Dolphin, procurement, and and then Transcoean’s semisub- construction of the fex- mersible, Polar Pioneer, which will ible pipelines, manufactured continue drilling this year. by Flexi France, and associated However, McHugh said: “Once equipment. the FPSO arrived in Stord (the

This infrastructure is spread Aker Stord yard), we found that the over 15sq km, with the 17 wells fnishing work was more extensive (seven oil producers, fve gas pro- than expected because of some pipe ducers and four gas injectors) at a work repairs, which had to be car- distance of between three and 14km ried out. Consequently, we stayed from the FPSO with 13 risers and in Stord for some weeks longer than 40km of infeld fowlines. initially planned.”

As part of the installation, and as Corrective work included repairs a result of signifcant scouring on to fange leaks in the turret and oedigital.com oedigital.com April 2013 | OE 5151 oe_epic_skarv.indd 51 4/1/13 2:30 AM

48

48

50

50