Page 102: of Offshore Engineer Magazine (May/Jun 2013)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2013 Offshore Engineer Magazine

assembly and winches. The barge The HOM is located inside of the umbilical ranging from 4-24in. OD.

will be moored at the quayside moonpool and has forward and aft In addition to the heavy-lift crane, where the pipe stalk will be pulled feeting capabilities that allow for the vessel has an 80Te telescopic over the stern using the winch, stowage during transit. A worksta- crane and an auxiliary hoist capable through the feeting tensioner and tion can be moved into place when of handling 10Te at any reach. The

Pipelines across the rolling support assem- the pipe is in the HOM. The work 80Te crane is used for auxiliary blies, as pipe is spooled onto the station is used for welding and coat- deck operations, PLET handling and reels. Once spooling is completed ing activities; it can be moved out of mobilization/demobilization of the for a reel, the spooling spread will the fring line during pipe transfers vessel.

be feeted into position for spooling or installation of large structures. The vertical reels used on the of the next reel. Upon completion of all spooling operations, the reel PLET handling system barge will be towed to the Lewek The PLET handling system (PHS) is

Constellation to complete the off- used to move either frst- or second- shore reel transfer. end PLETs up to 60Te into position

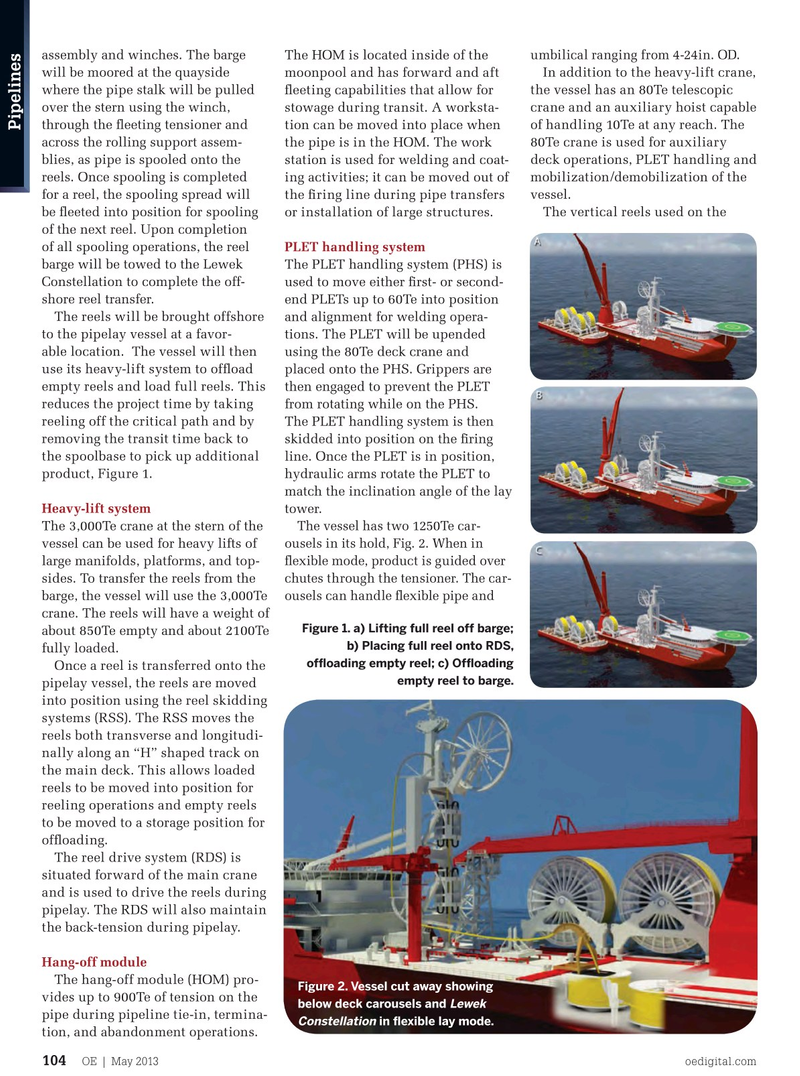

The reels will be brought offshore and alignment for welding opera- to the pipelay vessel at a favor- tions. The PLET will be upended able location. The vessel will then using the 80Te deck crane and use its heavy-lift system to offoad placed onto the PHS. Grippers are empty reels and load full reels. This then engaged to prevent the PLET reduces the project time by taking from rotating while on the PHS. reeling off the critical path and by The PLET handling system is then removing the transit time back to skidded into position on the fring the spoolbase to pick up additional line. Once the PLET is in position, product, Figure 1. hydraulic arms rotate the PLET to match the inclination angle of the lay

Heavy-lift system tower.

The vessel has two 1250Te car-

The 3,000Te crane at the stern of the ousels in its hold, Fig. 2. When in vessel can be used for heavy lifts of fexible mode, product is guided over large manifolds, platforms, and top- chutes through the tensioner. The car- sides. To transfer the reels from the ousels can handle fexible pipe and barge, the vessel will use the 3,000Te crane. The reels will have a weight of

Figure 1. a) Lifting full reel off barge; about 850Te empty and about 2100Te b) Placing full reel onto RDS, fully loaded.

offoading empty reel; c) Offoading

Once a reel is transferred onto the empty reel to barge.

pipelay vessel, the reels are moved into position using the reel skidding systems (RSS). The RSS moves the reels both transverse and longitudi- nally along an “H” shaped track on the main deck. This allows loaded reels to be moved into position for reeling operations and empty reels to be moved to a storage position for offoading.

The reel drive system (RDS) is situated forward of the main crane and is used to drive the reels during pipelay. The RDS will also maintain the back-tension during pipelay.

Hang-off module

The hang-off module (HOM) pro-

Figure 2. Vessel cut away showing vides up to 900Te of tension on the

Lewek below deck carousels and pipe during pipeline tie-in, termina- in fexible lay mode.

Constellation tion, and abandonment operations.

OE | May 2013 oedigital.com 104 fp2.indd 104 4/22/13 6:17 PM

101

101

103

103