Page 104: of Offshore Engineer Magazine (May/Jun 2013)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2013 Offshore Engineer Magazine

Pipelines

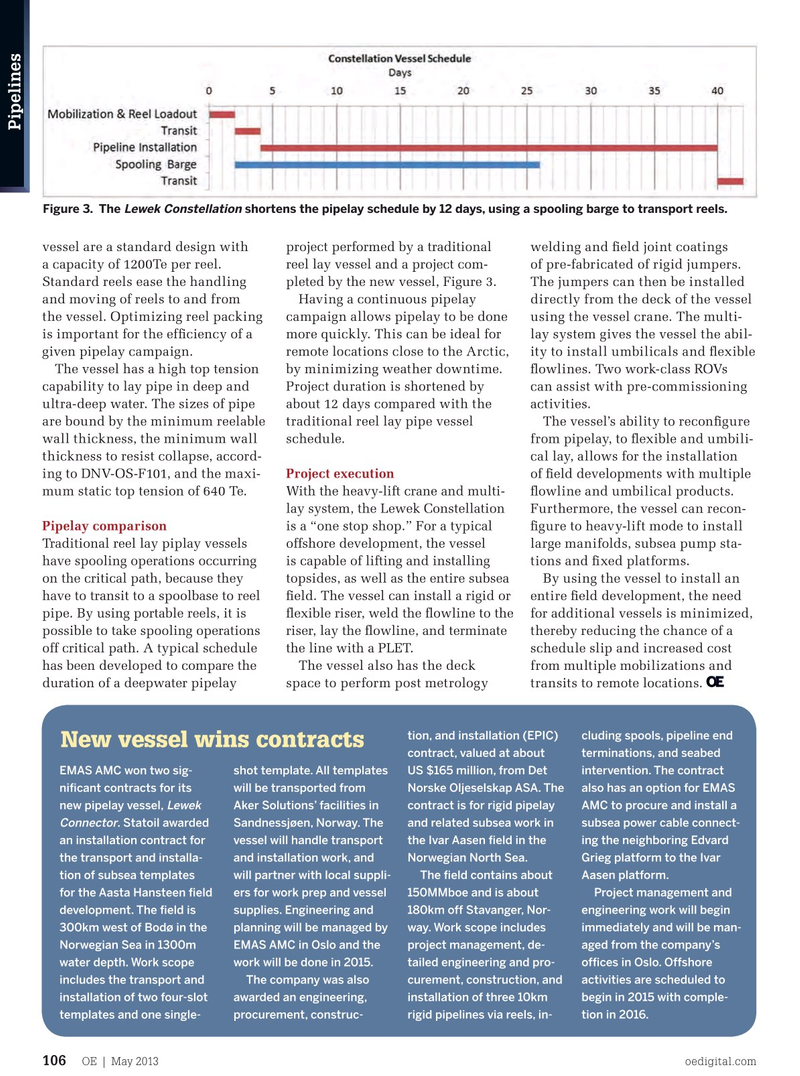

Figure 3. The shortens the pipelay schedule by 12 days, using a spooling barge to transport reels. Lewek Constellation vessel are a standard design with project performed by a traditional welding and feld joint coatings a capacity of 1200Te per reel. reel lay vessel and a project com- of pre-fabricated of rigid jumpers.

Standard reels ease the handling pleted by the new vessel, Figure 3. The jumpers can then be installed and moving of reels to and from Having a continuous pipelay directly from the deck of the vessel the vessel. Optimizing reel packing campaign allows pipelay to be done using the vessel crane. The multi- is important for the effciency of a more quickly. This can be ideal for lay system gives the vessel the abil- given pipelay campaign. remote locations close to the Arctic, ity to install umbilicals and fexible

The vessel has a high top tension by minimizing weather downtime. fowlines. Two work-class ROVs capability to lay pipe in deep and Project duration is shortened by can assist with pre-commissioning ultra-deep water. The sizes of pipe about 12 days compared with the activities.

are bound by the minimum reelable traditional reel lay pipe vessel The vessel’s ability to reconfgure wall thickness, the minimum wall schedule. from pipelay, to fexible and umbili- thickness to resist collapse, accord- cal lay, allows for the installation ing to DNV-OS-F101, and the maxi- Project execution of feld developments with multiple mum static top tension of 640 Te. With the heavy-lift crane and multi- fowline and umbilical products. lay system, the Lewek Constellation Furthermore, the vessel can recon-

Pipelay comparison is a “one stop shop.” For a typical fgure to heavy-lift mode to install

Traditional reel lay piplay vessels offshore development, the vessel large manifolds, subsea pump sta- have spooling operations occurring is capable of lifting and installing tions and fxed platforms. on the critical path, because they topsides, as well as the entire subsea By using the vessel to install an have to transit to a spoolbase to reel feld. The vessel can install a rigid or entire feld development, the need pipe. By using portable reels, it is fexible riser, weld the fowline to the for additional vessels is minimized, possible to take spooling operations riser, lay the fowline, and terminate thereby reducing the chance of a off critical path. A typical schedule the line with a PLET. schedule slip and increased cost has been developed to compare the The vessel also has the deck from multiple mobilizations and duration of a deepwater pipelay space to perform post metrology transits to remote locations. tion, and installation (EPIC) cluding spools, pipeline end

New vessel wins contracts contract, valued at about terminations, and seabed

EMAS AMC won two sig- shot template. All templates US $165 million, from Det intervention. The contract nifcant contracts for its will be transported from Norske Oljeselskap ASA. The also has an option for EMAS new pipelay vessel, Aker Solutions’ facilities in contract is for rigid pipelay AMC to procure and install a Lewek

Connector . Statoil awarded Sandnessjøen, Norway. The and related subsea work in subsea power cable connect- an installation contract for vessel will handle transport the Ivar Aasen feld in the ing the neighboring Edvard the transport and installa- and installation work, and Norwegian North Sea. Grieg platform to the Ivar tion of subsea templates will partner with local suppli- The feld contains about Aasen platform.

for the Aasta Hansteen feld ers for work prep and vessel 150MMboe and is about Project management and development. The feld is supplies. Engineering and 180km off Stavanger, Nor- engineering work will begin 300km west of Bodø in the planning will be managed by way. Work scope includes immediately and will be man-

Norwegian Sea in 1300m EMAS AMC in Oslo and the project management, de- aged from the company’s water depth. Work scope work will be done in 2015. tailed engineering and pro- offces in Oslo. Offshore includes the transport and The company was also curement, construction, and activities are scheduled to installation of two four-slot awarded an engineering, installation of three 10km begin in 2015 with comple- templates and one single- procurement, construc- rigid pipelines via reels, in- tion in 2016.

OE | May 2013 oedigital.com 106 fp2.indd 106 4/22/13 6:15 PM

103

103

105

105