Page 107: of Offshore Engineer Magazine (May/Jun 2013)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2013 Offshore Engineer Magazine

hulls will be re-joined afoat. ceived very accurate information and across its slot for removal or installa-

Vessels

While slightly delaying its fnal we saw that the slot width should be tion of topsides. They have a motion completion, the move will improve increased. We also realized that the compensation system to operate in

Pieter Schelte’s capacity, still well dock width at Daewoo was actually rough seas. The vessel will have two before Shell’s North Sea Brent de- 134m – a lot more than available a tilting lift beams on the stern, and commissioning project. long time ago.” laydown space for the installation or

Edward Heerema, Allseas’ presi- It is an evolving project. Edward removal of jackets. It will be pow- dent and the creator of the Pieter Heerema’s concept for the Pieter ered by eight main diesel generators,

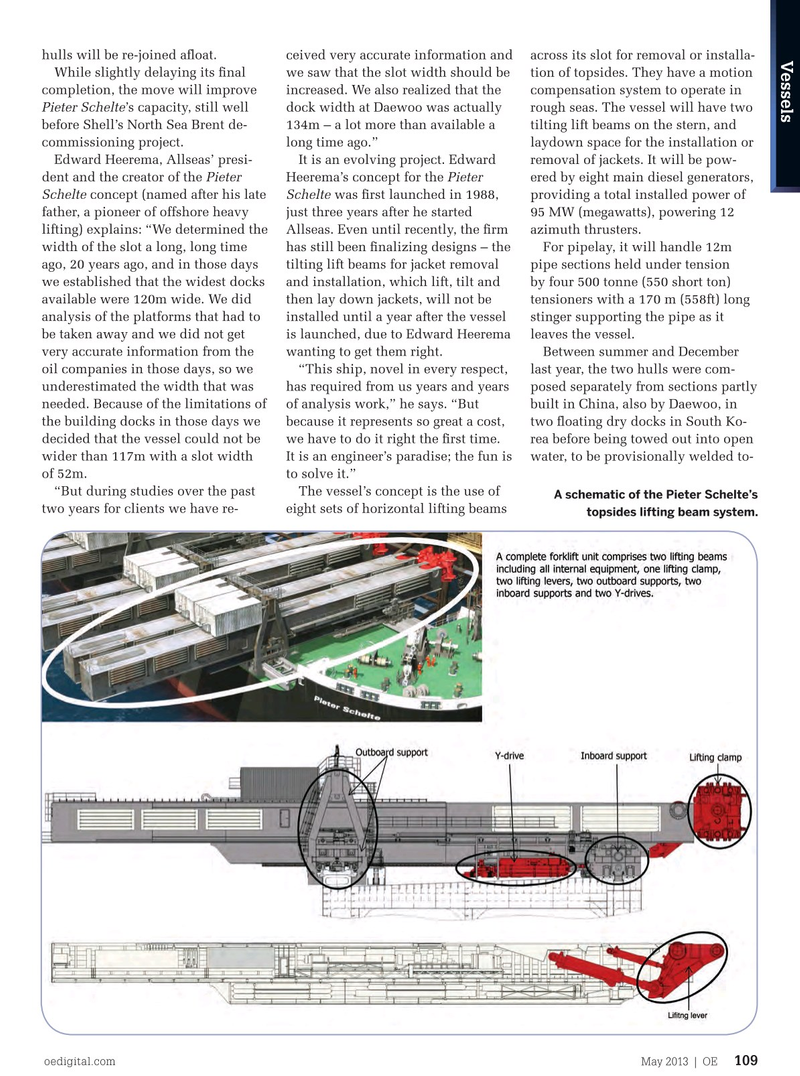

Schelte concept (named after his late Schelte was frst launched in 1988, providing a total installed power of father, a pioneer of offshore heavy just three years after he started 95 MW (megawatts), powering 12 lifting) explains: “We determined the Allseas. Even until recently, the frm azimuth thrusters. width of the slot a long, long time has still been fnalizing designs – the For pipelay, it will handle 12m ago, 20 years ago, and in those days tilting lift beams for jacket removal pipe sections held under tension we established that the widest docks and installation, which lift, tilt and by four 500 tonne (550 short ton) available were 120m wide. We did then lay down jackets, will not be tensioners with a 170 m (558ft) long analysis of the platforms that had to installed until a year after the vessel stinger supporting the pipe as it be taken away and we did not get is launched, due to Edward Heerema leaves the vessel. very accurate information from the wanting to get them right. Between summer and December oil companies in those days, so we “This ship, novel in every respect, last year, the two hulls were com- underestimated the width that was has required from us years and years posed separately from sections partly needed. Because of the limitations of of analysis work,” he says. “But built in China, also by Daewoo, in the building docks in those days we because it represents so great a cost, two foating dry docks in South Ko- decided that the vessel could not be we have to do it right the frst time. rea before being towed out into open wider than 117m with a slot width It is an engineer’s paradise; the fun is water, to be provisionally welded to- of 52m. to solve it.” “But during studies over the past The vessel’s concept is the use of

A schematic of the Pieter Schelte’s two years for clients we have re- eight sets of horizontal lifting beams topsides lifting beam system.

oedigital.com May 2013 | OE 109

Vessels1_AllSeas-Elaine.indd 109 4/22/13 7:17 PM

106

106

108

108