Page 112: of Offshore Engineer Magazine (May/Jun 2013)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2013 Offshore Engineer Magazine

commitments for its eight vessels operating off West Africa. Most of the vessels operate off Angola (Blocks 15, 17, 18, and 31), with

Vessels some in support of Nigeria’s Bonga and Akpo felds. Both of the Bour- bon Evolution 803’s sister ships,

Ungundja, and Bourbon Evolution 802, operate off West Africa. The Ungundja, the inaugural

Evolution-design vessel, entered the feet in December 2011 and is working off Angola. It has installed numerous jumpers and subsea trees on the Dalia and Pazfor felds. Ten months later in September 2012, the

Bourbon Evolution 802 joined the feet. It operates off Nigeria (OE April 2012).

The company began its IMR-vessel

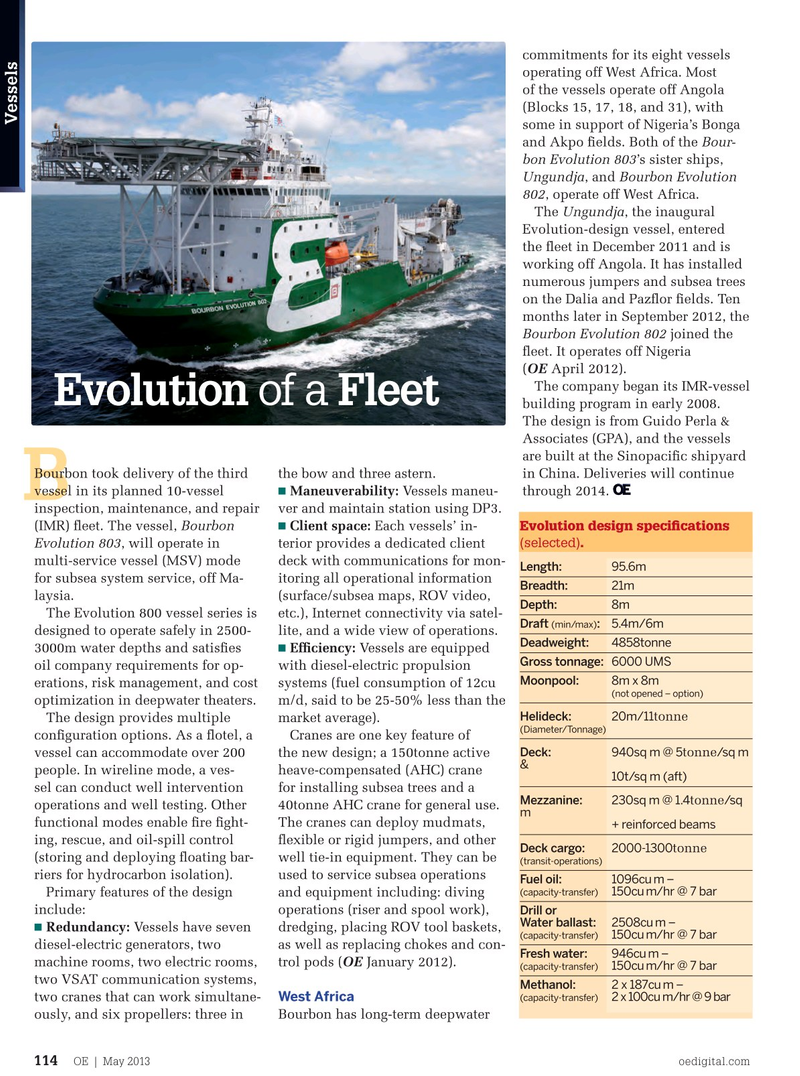

Evolution of a Fleet building program in early 2008.

The design is from Guido Perla &

Associates (GPA), and the vessels are built at the Sinopacifc shipyard

Bourbon took delivery of the third the bow and three astern. in China. Deliveries will continue ¦ vessel in its planned 10-vessel Maneuverability: Vessels maneu- through 2014.

B inspection, maintenance, and repair ver and maintain station using DP3. ¦ (IMR) feet. The vessel, Bourbon Client space: Each vessels’ in-

Evolution design specifcations (selected).

Evolution 803, will operate in terior provides a dedicated client multi-service vessel (MSV) mode deck with communications for mon-

Length: 95.6m for subsea system service, off Ma- itoring all operational information

Breadth: 21m laysia. (surface/subsea maps, ROV video,

Depth: 8m The Evolution 800 vessel series is etc.), Internet connectivity via satel- (min/max)

Draft : 5 .4m/6m designed to operate safely in 2500- lite, and a wide view of operations.

Deadweight: 4858tonne ¦ 3000m water depths and satisfes Effciency: Vessels are equipped

Gross tonnage: 6000 UMS oil company requirements for op- with diesel-electric propulsion

Moonpool: 8m x 8m erations, risk management, and cost systems (fuel consumption of 12cu (not opened – option) optimization in deepwater theaters. m/d, said to be 25-50% less than the

Helideck: 20m/11 tonne The design provides multiple market average).

(Diameter/Tonnage) confguration options. As a fotel, a Cranes are one key feature of

Deck: 940sq m @ 5 /sq m tonne vessel can accommodate over 200 the new design; a 150tonne active & people. In wireline mode, a ves- heave-compensated (AHC) crane 10t/sq m (aft) sel can conduct well intervention for installing subsea trees and a tonne

Mezzanine: 230sq m @ 1.4 /sq operations and well testing. Other 40tonne AHC crane for general use. m functional modes enable fre fght- The cranes can deploy mudmats, + reinforced beams ing, rescue, and oil-spill control fexible or rigid jumpers, and other tonne

Deck cargo: 2000-1300 (storing and deploying foating bar- well tie-in equipment. They can be (transit-operations) riers for hydrocarbon isolation). used to service subsea operations

Fuel oil: 1096cu m – 150c u m/hr @ 7 bar (capacity-transfer) Primary features of the design and equipment including: diving include: operations (riser and spool work),

Drill or

Water ballast: 2508cu m – ¦ Redundancy: Vessels have seven dredging, placing ROV tool baskets, (capacity-transfer) 150c u m/hr @ 7 bar diesel-electric generators, two as well as replacing chokes and con-

Fresh water: 946cu m – machine rooms, two electric rooms, trol pods (OE January 2012).

(capacity-transfer) 150c u m/hr @ 7 bar two VSAT communication systems,

Methanol: 2 x 187cu m – 2 x 1 00cu m/hr @ 9 bar (capacity-transfer) two cranes that can work simultane- West Africa ously, and six propellers: three in Bourbon has long-term deepwater

OE | May 2013 oedigital.com 114 oe_Bourbon.indd 114 4/22/13 5:05 PM

111

111

113

113