Page 118: of Offshore Engineer Magazine (May/Jun 2013)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2013 Offshore Engineer Magazine

tion refrigeration technology that produces chilled water using waste heat from gas turbine exhaust. This

New process brings process is already used in centralized

Vessels mega air conditioning systems on-

FLNG to small and shore and to date in excess of 10,000 such units have been delivered, with the largest in operation for over fve mid-size felds years.

The system integrates the LiBro

The concept has been devel- unit with Air Products AP-N LNG

As FLNG starts to oped by ship classifcation society Process so that the chilled water take off on a large scale,

ClassNK, Tokyo-based foating produced in the unit pre-cools the a consortium of companies production supplier/operator Modec natural gas and N2 refrigerant, result- is looking to make it and plant manufacturer Toyo Engi- ing in improved LNG train effciency. neering – and it has already secured Chilled water is also used for cool- a more cost effective and its frst front end engineering design ing the gas turbine combustion air, compact proposition.

(FEED) contract with Malaysia’s maximizing output of the gas turbine

A consortium of companies has Petronas. driver and improving the overall ef- designed a new foating LNG (FLNG) The consortium says that while fciency of the LNG train. system specifcally aimed at small to many FLNG systems are primarily at- In addition, the cooling system mid-size gas felds. tempts to take onshore LNG technol- uses non-fammable nitrogen instead

LiBro FLNG is a system that hopes ogy and adapt it to offshore uses, the of fammable hydrocarbons such as to use an alternative cooling process LiBro FLNG system has been devel- methane, ethane, or propane, used in making use of waste heat from gas oped specifcally for use offshore. most FLNG systems, to cool and liq- turbine exhausts instead of using The core technology behind the uefy the gas. The latter increase both fammable substances. This in turn system is a combination of Modec’s environmental and safety concerns allows for more conventional and LiBro technology with Air Products’ and mean accommodation space smaller vessels to be used for FLNG. Triple N2 Expander Liquefaction must be kept at a safe distance – in-

It also proposes use of existing technology. creasing hull-size specifcations. tank systems, which could be retro- While the safety of N2 refriger- The system is currently being used ftted to vessels, further opening up ants is widely accepted, the lim- in the FEED of FLNG projects under use of standard vessels, increasing ited effciency of such systems has development, says the group. the number of yards able to complete prevented their widespread use in This includes a FEED contract such projects, and potentially mak- FLNG systems, says the group. The of an FLNG unit from Malaysian ing conversions of existing vessels a technology addresses these concerns National Oil Company Petroliam practical possibility. by using Lithium Bromide absorp- Nasional Berhad (Petronas). This will be Petronas’ second FLNG unit and

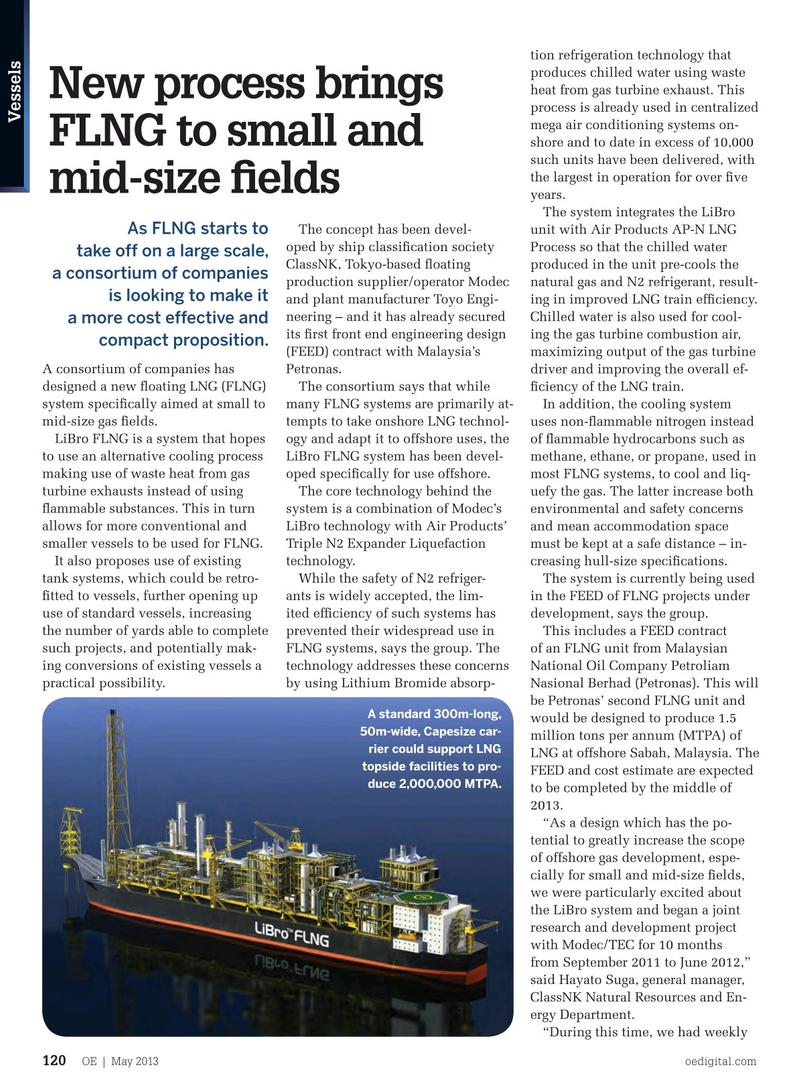

A standard 300m-long, would be designed to produce 1.5 50m-wide, Capesize car- million tons per annum (MTPA) of rier could support LNG

LNG at offshore Sabah, Malaysia. The topside facilities to pro-

FEED and cost estimate are expected duce 2,000,000 MTPA.

to be completed by the middle of 2013.

“As a design which has the po- tential to greatly increase the scope of offshore gas development, espe- cially for small and mid-size felds, we were particularly excited about the LiBro system and began a joint research and development project with Modec/TEC for 10 months from September 2011 to June 2012,” said Hayato Suga, general manager,

ClassNK Natural Resources and En- ergy Department.

“During this time, we had weekly

OE | May 2013 oedigital.com 120

Vessels4-Libro.indd 120 4/22/13 7:28 PM

117

117

119

119