Page 54: of Offshore Engineer Magazine (May/Jun 2013)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2013 Offshore Engineer Magazine

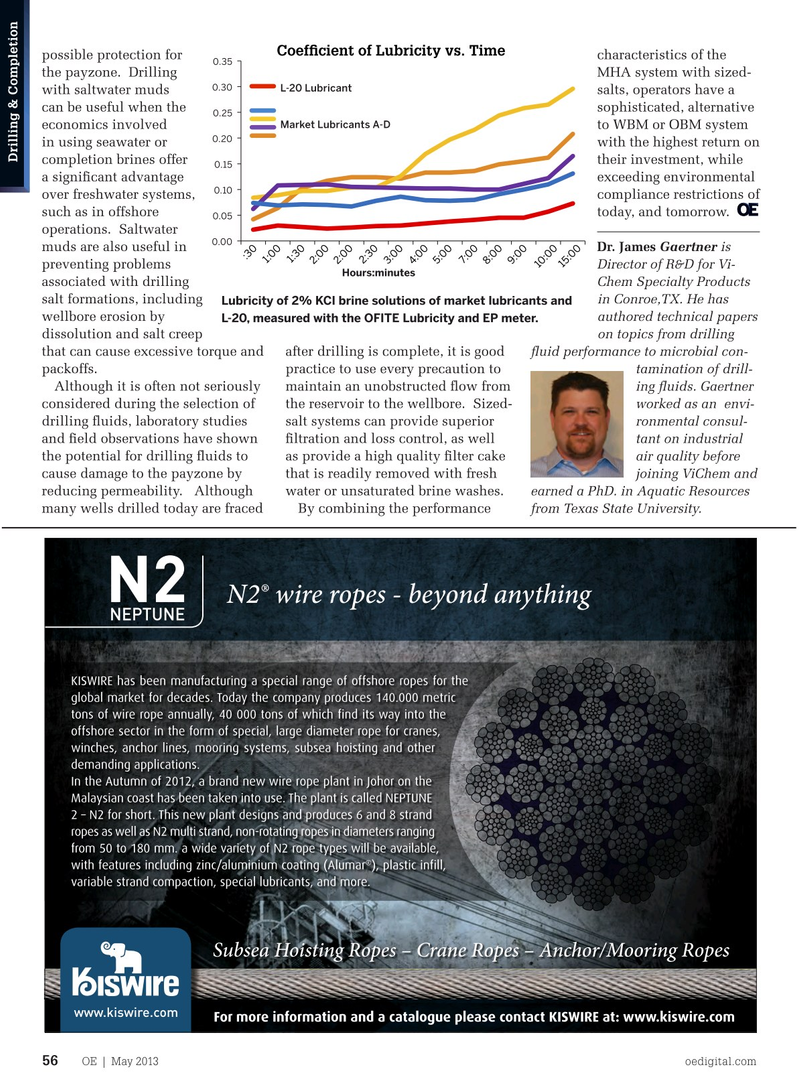

Coef?cient of Lubricity vs. Time possible protection for characteristics of the 0.35 the payzone. Drilling MHA system with sized- 0.30

L-20 Lubricant with saltwater muds salts, operators have a can be useful when the sophisticated, alternative 0.25

Market Lubricants A-D economics involved to WBM or OBM system 0.20 in using seawater or with the highest return on

Drilling & Completion completion brines offer their investment, while 0.15 a signifcant advantage exceed ing environmental 0.10 over freshwater systems, compliance restrictions of such as in offshore today, and tomorrow. 0.05 operations. Saltwater 0.00 muds are also useful in

Dr. James Gaertner is :30 1:30 1:00 7:00 2:30 5:00 2:00 3:00 2:00 4:00 8:00 9:00 15:00 10:00 preventing problems

Director of R&D for Vi-

Hours:minutes associated with drilling

Chem Specialty Products salt formations, including in Conroe,TX. He has

Lubricity of 2% KCl brine solutions of market lubricants and wellbore erosion by authored technical papers

L-20, measured with the OFITE Lubricity and EP meter.

dissolution and salt creep on topics from drilling that can cause excessive torque and after drilling is complete, it is good fuid performance to microbial con- packoffs. practice to use every precaution to tamination of drill-

Although it is often not seriously maintain an unobstructed fow from ing fuids. Gaertner considered during the selection of the reservoir to the wellbore. Sized- worked as an envi- drilling fuids, laboratory studies salt systems can provide superior ronmental consul- and feld observations have shown fltration and loss control, as well tant on industrial the potential for drilling fuids to as provide a high quality flter cake air quality before cause damage to the payzone by that is readily removed with fresh joining ViChem and reducing permeability. Although water or unsaturated brine washes. earned a PhD. in Aquatic Resources many wells drilled today are fraced By combining the performance from Texas State University.

N2® wire ropes - beyond anything

KISWIRE has been manufacturing a special range of offshore ropes for the global market for decades. Today the company produces 140.000 metric tons of wire rope annually, 40 000 tons of which fnd its way into the offshore sector in the form of special, large diameter rope for cranes, winches, anchor lines, mooring systems, subsea hoisting and other demanding applications.

In the Autumn of 2012, a brand new wire rope plant in Johor on the

Malaysian coast has been taken into use. The plant is called NEPTUNE 2 – N2 for short. This new plant designs and produces 6 and 8 strand ropes as well as N2 multi strand, non-rotating ropes in diameters ranging from 50 to 180 mm. a wide variety of N2 rope types will be available, ® with features including zinc/aluminium coating (Alumar ), plastic infll, variable strand compaction, special lubricants, and more.

Subsea Hoisting Ropes – Crane Ropes – Anchor/Mooring Ropes www.kiswire.com

For more information and a catalogue please contact KISWIRE at: www.kiswire.com

OE | May 2013 oedigital.com 56

DC2 Fluids.indd 56 4/22/13 4:52 PM

53

53

55

55