Page 95: of Offshore Engineer Magazine (May/Jun 2013)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2013 Offshore Engineer Magazine

Pipelines safety risk.

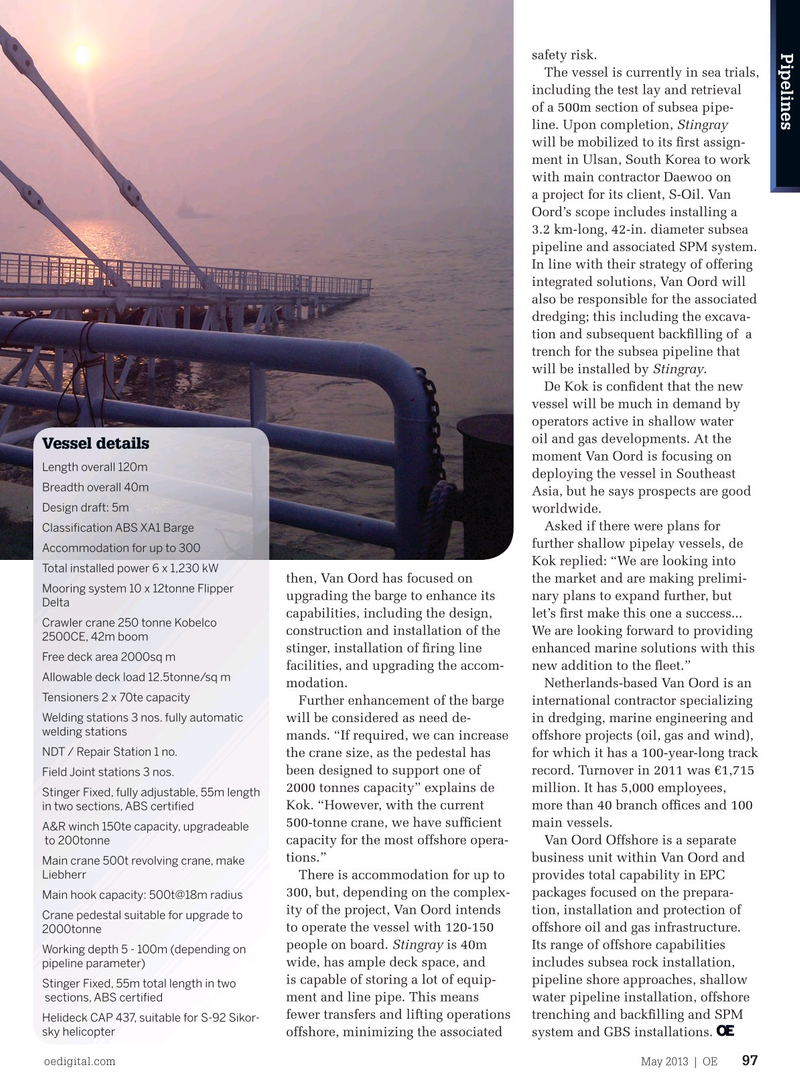

The vessel is currently in sea trials, including the test lay and retrieval of a 500m section of subsea pipe- line. Upon completion, Stingray will be mobilized to its frst assign- ment in Ulsan, South Korea to work with main contractor Daewoo on a project for its client, S-Oil. Van

Oord’s scope includes installing a 3.2 km-long, 42-in. diameter subsea pipeline and associated SPM system.

In line with their strategy of offering integrated solutions, Van Oord will also be responsible for the associated dredging; this including the excava- tion and subsequent backflling of a trench for the subsea pipeline that will be installed by Stingray.

De Kok is confdent that the new vessel will be much in demand by operators active in shallow water oil and gas developments. At the

Vessel details moment Van Oord is focusing on

Length overall 120m deploying the vessel in Southeast

Breadth overall 40m

Asia, but he says prospects are good

Design draft: 5m worldwide.

Asked if there were plans for

Classifcation ABS XA1 Barge further shallow pipelay vessels, de

Accommodation for up to 300

Kok replied: “We are looking into

Total installed power 6 x 1,230 kW then, Van Oord has focused on the market and are making prelimi-

Mooring system 10 x 12tonne Flipper upgrading the barge to enhance its nary plans to expand further, but

Delta capabilities, including the design, let’s frst make this one a success...

Crawler crane 250 tonne Kobelco construction and installation of the We are looking forward to providing 2500CE, 42m boom stinger, installation of fring line enhanced marine solutions with this

Free deck area 2000sq m facilities, and upgrading the accom- new addition to the feet.”

Allowable deck load 12.5tonne/sq m modation. Netherlands-based Van Oord is an

Tensioners 2 x 70te capacity

Further enhancement of the barge international contractor specializing

Welding stations 3 nos. fully automatic will be considered as need de- in dredging, marine engineering and welding stations mands. “If required, we can increase offshore projects (oil, gas and wind),

NDT / Repair Station 1 no.

the crane size, as the pedestal has for which it has a 100-year-long track been designed to support one of record. Turnover in 2011 was €1,715

Field Joint stations 3 nos.

2000 tonnes capacity” explains de million. It has 5,000 employees,

Stinger Fixed, fully adjustable, 55m length

Kok. “However, with the current more than 40 branch offces and 100 in two sections, ABS certifed 500-tonne crane, we have suffcient main vessels.

A&R winch 150te capacity, upgradeable capacity for the most offshore opera- Van Oord Offshore is a separate to 200tonne tions.” business unit within Van Oord and

Main crane 500t revolving crane, make

Liebherr

There is accommodation for up to provides total capability in EPC 300, but, depending on the complex- packages focused on the prepara-

Main hook capacity: 500t@18m radius ity of the project, Van Oord intends tion, installation and protection of

Crane pedestal suitable for upgrade to to operate the vessel with 120-150 offshore oil and gas infrastructure.

2000tonne people on board. Stingray is 40m Its range of offshore capabilities

Working depth 5 - 100m (depending on wide, has ample deck space, and includes subsea rock installation, pipeline parameter) is capable of storing a lot of equip- pipeline shore approaches, shallow

Stinger Fixed, 55m total length in two ment and line pipe. This means water pipeline installation, offshore sections, ABS certifed fewer transfers and lifting operations trenching and backflling and SPM

Helideck CAP 437, suitable for S-92 Sikor- sky helicopter offshore, minimizing the associated system and GBS installations. oedigital.com May 2013 | OE 97

Pipeline.indd 97 4/22/13 6:10 PM

94

94

96

96