Page 34: of Offshore Engineer Magazine (Jun/Jul 2013)

Read this page in Pdf, Flash or Html5 edition of Jun/Jul 2013 Offshore Engineer Magazine

Production

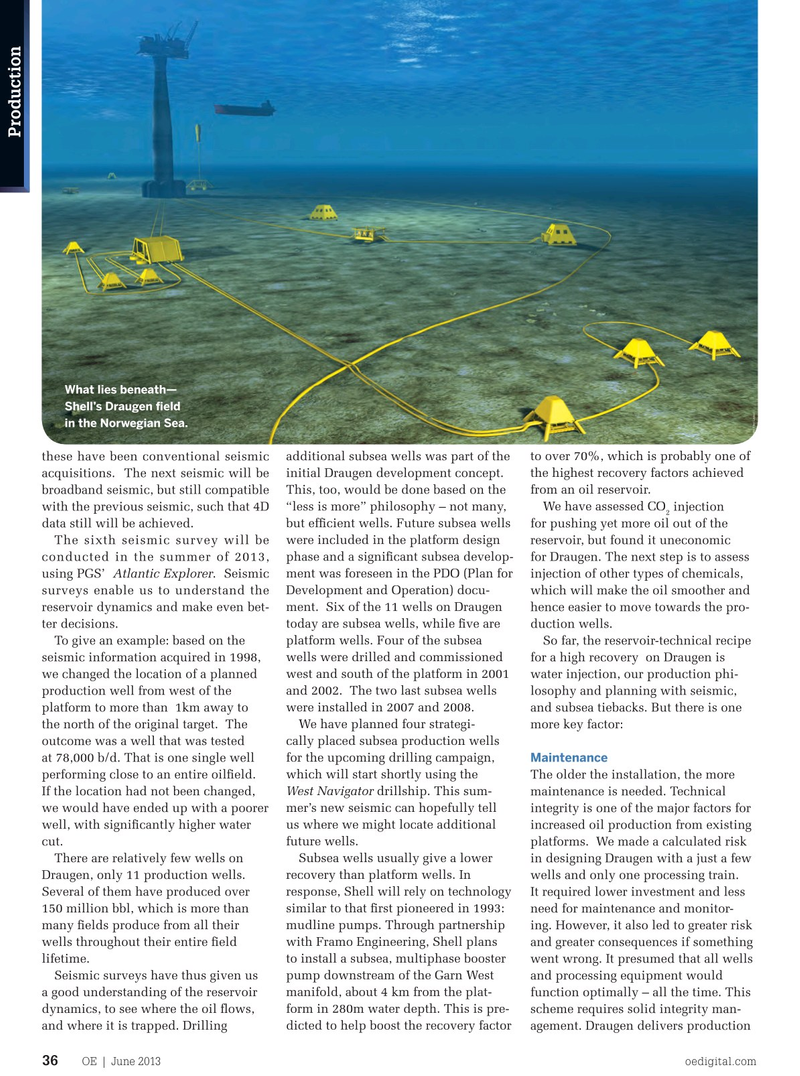

What lies beneath—

Shell’s Draugen feld in the Norwegian Sea.

these have been conventional seismic additional subsea wells was part of the to over 70%, which is probably one of acquisitions. The next seismic will be initial Draugen development concept. the highest recovery factors achieved broadband seismic, but still compatible This, too, would be done based on the from an oil reservoir. with the previous seismic, such that 4D “less is more” philosophy – not many, We have assessed CO injection 2 data still will be achieved. but effcient wells. Future subsea wells for pushing yet more oil out of the

The sixth seismic survey will be were included in the platform design reservoir, but found it uneconomic conducted in the summer of 2013, phase and a signifcant subsea develop- for Draugen. The next step is to assess using PGS’ Atlantic Explorer. Seismic ment was foreseen in the PDO (Plan for injection of other types of chemicals, surveys enable us to understand the Development and Operation) docu- which will make the oil smoother and reservoir dynamics and make even bet- ment. Six of the 11 wells on Draugen hence easier to move towards the pro- ter decisions. today are subsea wells, while fve are duction wells.

To give an example: based on the platform wells. Four of the subsea So far, the reservoir-technical recipe seismic information acquired in 1998, wells were drilled and commissioned for a high recovery on Draugen is we changed the location of a planned west and south of the platform in 2001 water injection, our production phi- production well from west of the and 2002. The two last subsea wells losophy and planning with seismic, platform to more than 1km away to were installed in 2007 and 2008. and subsea tiebacks. But there is one the north of the original target. The We have planned four strategi- more key factor: outcome was a well that was tested cally placed subsea production wells at 78,000 b/d. That is one single well for the upcoming drilling campaign,

Maintenance performing close to an entire oilfeld. which will start shortly using the The older the installation, the more

If the location had not been changed, West Navigator drillship. This sum- maintenance is needed. Technical we would have ended up with a poorer mer’s new seismic can hopefully tell integrity is one of the major factors for well, with signifcantly higher water us where we might locate additional increased oil production from existing cut. future wells. platforms. We made a calculated risk

There are relatively few wells on Subsea wells usually give a lower in designing Draugen with a just a few

Draugen, only 11 production wells. recovery than platform wells. In wells and only one processing train.

Several of them have produced over response, Shell will rely on technology It required lower investment and less 150 million bbl, which is more than similar to that frst pioneered in 1993: need for maintenance and monitor- many felds produce from all their mudline pumps. Through partnership ing. However, it also led to greater risk wells throughout their entire feld with Framo Engineering, Shell plans and greater consequences if something lifetime. to install a subsea, multiphase booster went wrong. It presumed that all wells

Seismic surveys have thus given us pump downstream of the Garn West and processing equipment would a good understanding of the reservoir manifold, about 4 km from the plat- function optimally – all the time. This dynamics, to see where the oil fows, form in 280m water depth. This is pre- scheme requires solid integrity man- and where it is trapped. Drilling dicted to help boost the recovery factor agement. Draugen delivers production

OE | June 2013 oedigital.com 36 035OE_0613_ProdOps-1- Draugen.indd 36 5/27/13 4:04 PM

33

33

35

35