Page 52: of Offshore Engineer Magazine (Jul/Aug 2013)

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2013 Offshore Engineer Magazine

Production

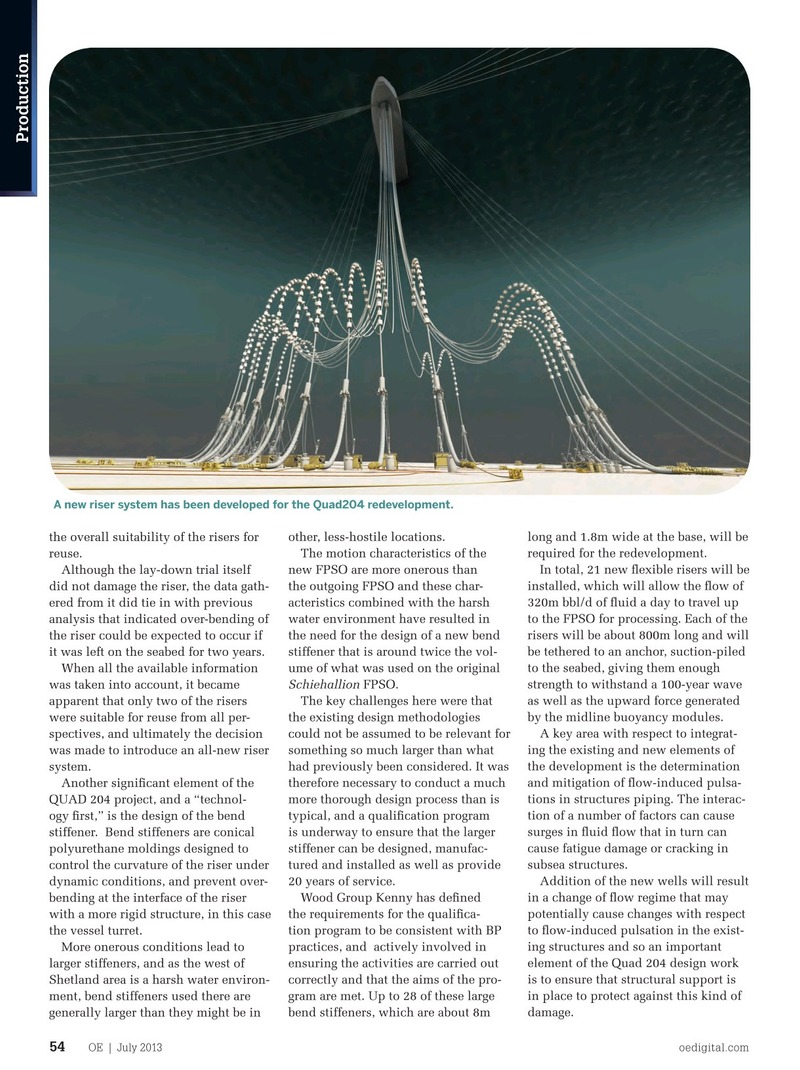

A new riser system has been developed for the Quad204 redevelopment. the overall suitability of the risers for other, less-hostile locations. long and 1.8m wide at the base, will be reuse. The motion characteristics of the required for the redevelopment.

Although the lay-down trial itself new FPSO are more onerous than In total, 21 new fexible risers will be did not damage the riser, the data gath- the outgoing FPSO and these char- installed, which will allow the fow of ered from it did tie in with previous acteristics combined with the harsh 320m bbl/d of fuid a day to travel up analysis that indicated over-bending of water environment have resulted in to the FPSO for processing. Each of the the riser could be expected to occur if the need for the design of a new bend risers will be about 800m long and will it was left on the seabed for two years. stiffener that is around twice the vol- be tethered to an anchor, suction-piled

When all the available information ume of what was used on the original to the seabed, giving them enough was taken into account, it became Schiehallion FPSO. strength to withstand a 100-year wave apparent that only two of the risers The key challenges here were that as well as the upward force generated were suitable for reuse from all per- the existing design methodologies by the midline buoyancy modules.

spectives, and ultimately the decision could not be assumed to be relevant for A key area with respect to integrat- was made to introduce an all-new riser something so much larger than what ing the existing and new elements of system. had previously been considered. It was the development is the determination

Another signifcant element of the therefore necessary to conduct a much and mitigation of fow-induced pulsa-

QUAD 204 project, and a “technol- more thorough design process than is tions in structures piping. The interac- ogy frst,” is the design of the bend typical, and a qualifcation program tion of a number of factors can cause stiffener. Bend stiffeners are conical is underway to ensure that the larger surges in fuid fow that in turn can polyurethane moldings designed to stiffener can be designed, manufac- cause fatigue damage or cracking in control the curvature of the riser under tured and installed as well as provide subsea structures. dynamic conditions, and prevent over- 20 years of service. Addition of the new wells will result bending at the interface of the riser Wood Group Kenny has defned in a change of fow regime that may with a more rigid structure, in this case the requirements for the qualifca- potentially cause changes with respect the vessel turret. tion program to be consistent with BP to fow-induced pulsation in the exist-

More onerous conditions lead to practices, and actively involved in ing structures and so an important larger stiffeners, and as the west of ensuring the activities are carried out element of the Quad 204 design work

Shetland area is a harsh water environ- correctly and that the aims of the pro- is to ensure that structural support is ment, bend stiffeners used there are gram are met. Up to 28 of these large in place to protect against this kind of generally larger than they might be in bend stiffeners, which are about 8m damage.

OE | July 2013 oedigital.com 54 052ProdOps2_BPQuad204.indd 54 6/25/13 1:04 PM

51

51

53

53