Page 24: of Offshore Engineer Magazine (Aug/Sep 2013)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2013 Offshore Engineer Magazine

Decommissioning

Clearing infrastructure– from the Gulf of Mexico to the North Sea

Technology can be transferred from the Gulf of Mexico to new markets such as the North

Sea and beyond. Scott Adams, sales manager of Decommissioning Services, and Caroline

Grant, Operations Manager, provide insight from

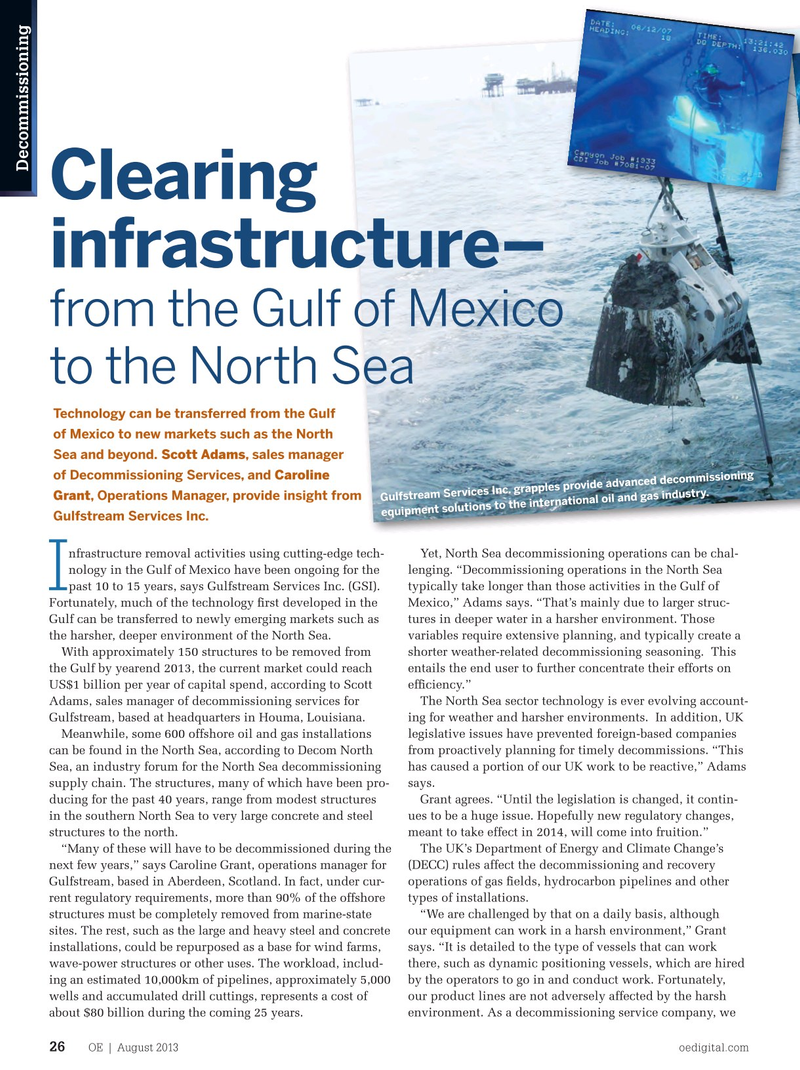

Gulfstream Services Inc. grapples provide advanced decommissioning equipment solutions to the international oil and gas industry.

Gulfstream Services Inc.

nfrastructure removal activities using cutting-edge tech- Yet, North Sea decommissioning operations can be chal- nology in the Gulf of Mexico have been ongoing for the lenging. “Decommissioning operations in the North Sea past 10 to 15 years, says Gulfstream Services Inc. (GSI). typically take longer than those activities in the Gulf of

I

Fortunately, much of the technology frst developed in the Mexico,” Adams says. “That’s mainly due to larger struc-

Gulf can be transferred to newly emerging markets such as tures in deeper water in a harsher environment. Those the harsher, deeper environment of the North Sea. variables require extensive planning, and typically create a

With approximately 150 structures to be removed from shorter weather-related decommissioning seasoning. This the Gulf by yearend 2013, the current market could reach entails the end user to further concentrate their efforts on

US$1 billion per year of capital spend, according to Scott effciency.”

Adams, sales manager of decommissioning services for The North Sea sector technology is ever evolving account-

Gulfstream, based at headquarters in Houma, Louisiana. ing for weather and harsher environments. In addition, UK

Meanwhile, some 600 offshore oil and gas installations legislative issues have prevented foreign-based companies can be found in the North Sea, according to Decom North from proactively planning for timely decommissions. “This

Sea, an industry forum for the North Sea decommissioning has caused a portion of our UK work to be reactive,” Adams supply chain. The structures, many of which have been pro- says.

ducing for the past 40 years, range from modest structures Grant agrees. “Until the legislation is changed, it contin- in the southern North Sea to very large concrete and steel ues to be a huge issue. Hopefully new regulatory changes, structures to the north. meant to take effect in 2014, will come into fruition.” “Many of these will have to be decommissioned during the The UK’s Department of Energy and Climate Change’s next few years,” says Caroline Grant, operations manager for (DECC) rules affect the decommissioning and recovery

Gulfstream, based in Aberdeen, Scotland. In fact, under cur- operations of gas felds, hydrocarbon pipelines and other rent regulatory requirements, more than 90% of the offshore types of installations. structures must be completely removed from marine-state “We are challenged by that on a daily basis, although sites. The rest, such as the large and heavy steel and concrete our equipment can work in a harsh environment,” Grant installations, could be repurposed as a base for wind farms, says. “It is detailed to the type of vessels that can work wave-power structures or other uses. The workload, includ- there, such as dynamic positioning vessels, which are hired ing an estimated 10,000km of pipelines, approximately 5,000 by the operators to go in and conduct work. Fortunately, wells and accumulated drill cuttings, represents a cost of our product lines are not adversely affected by the harsh about $80 billion during the coming 25 years. environment. As a decommissioning service company, we

OE | August 2013 oedigital.com 26 026_OE0813_Decom_1.indd 26 7/22/13 12:23 AM

23

23

25

25