Page 47: of Offshore Engineer Magazine (Aug/Sep 2013)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2013 Offshore Engineer Magazine

EPIC – Heave of a project, leading to a tailored any risk of resonance. In an AHC

Van Eerten—Jumbo

There has been a passive compensator [that is] able to system, resonance is hard to manage growing interest accomplish a desired landing speed and, when it occurs, the damage can in AHC sys- at the ideal pressure balance for dif- be substantial. When using PHC, the tems, as well as ferent circumstances. load also remains stationary after combined AHC Once overboard, the hydrody- landing. and PHC sys- namic forces are relatively easy to The hoist and heave systems are tems, with many overcome as drag and added mass independent, making the system tenders today can be fairly accurately predicted safer. PHC can also be used with a

Patrick van specifying AHC and total forces can be absorbed or “normal” crane, simply by adding a

Eerten, director offshore, Jumbo systems. minimized. heave compensation cylinder. PHC

However, very few [people] For example, landing speed can also requires no external power, actually understand these systems. be achieved at below 0.5m/s with making [possible] the design a fail-

While AHC systems have many good resistance control, using a far safe system to reduce wave impact advantages, we see several limita- less complex, more robust and safer on subsea operations.

tions to their use. system than AHC. There are some instances where

Jumbo prefers an engineered-solu- PHC is a very straightforward you have to use AHC, no doubt. But, tion, using PHC, based on experi- hydraulic cylinder and a gas in general, you do not need it. ence of maritime heavy lifting and accumulator. The piston’s load is More advanced equipment, ship motion. Lessons learnt have led balanced by nitrogen pressure and technology, and offshore lifting to the development of calculations the stiffness depends on the nitrogen procedures can be the right answer, to fne-tune the interaction between volume. but there is no need for it to be too heavy lifting and ship motion. As the load is compensated at complex. Preparation of equipment,

The motions are carefully calcu- exactly the same frequency as the personnel, and procedures are what lated during the engineering-phase motion of the waves, there is hardly are important. n and built a combination of both sys- Both AHC and PHC systems have We believe in the combination of tems on our offshore cranes. advantages and disadvantages, which both systems to increase the value of

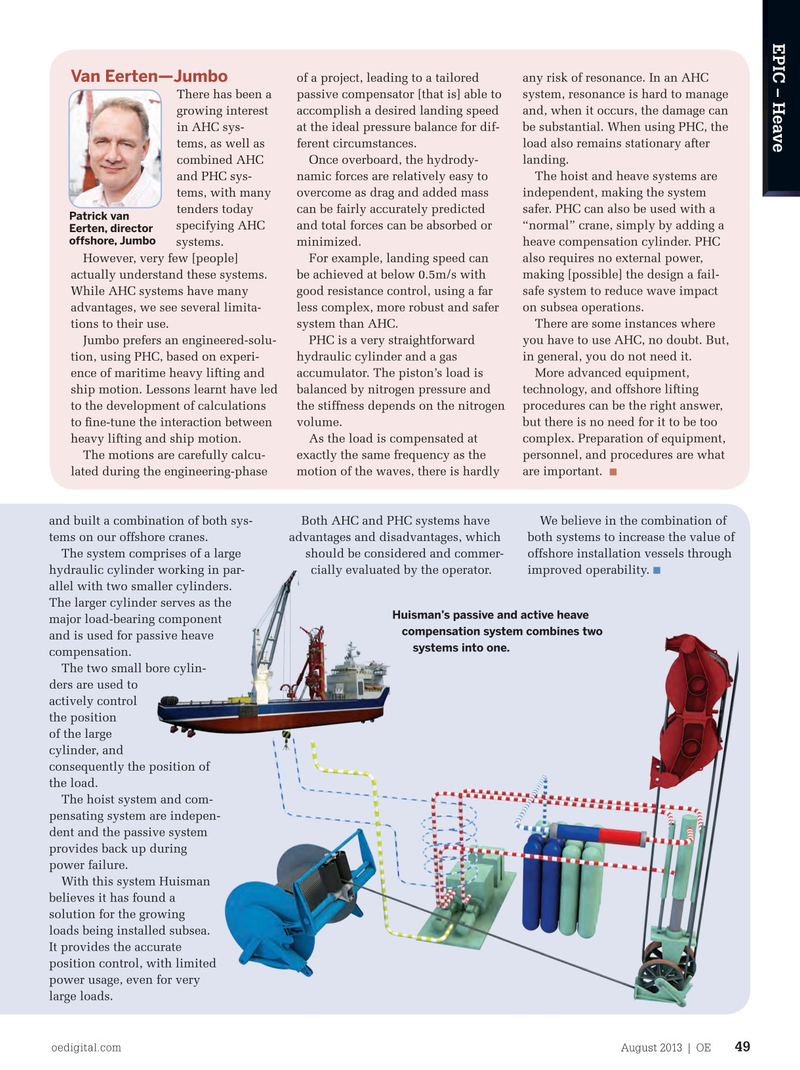

The system comprises of a large should be considered and commer- offshore installation vessels through hydraulic cylinder working in par- cially evaluated by the operator. improved operability. n allel with two smaller cylinders.

The larger cylinder serves as the

Huisman’s passive and active heave major load-bearing component compensation system combines two and is used for passive heave systems into one.

compensation.

The two small bore cylin- ders are used to actively control the position of the large cylinder, and consequently the position of the load.

The hoist system and com- pensating system are indepen- dent and the passive system provides back up during power failure.

With this system Huisman believes it has found a solution for the growing loads being installed subsea.

It provides the accurate position control, with limited power usage, even for very large loads. oedigital.com August 2013 | OE 49 048_OE0813_EPIC1_Heave.indd 49 7/22/13 12:36 AM

46

46

48

48