Page 102: of Offshore Engineer Magazine (Sep/Oct 2013)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2013 Offshore Engineer Magazine

be approved for permit on a project-by- Concrete or sand bags – also referred are not always permanent solutions, project basis by the Bureau of Ocean to as sling bags - are the closest off- either, as they are not as stable as mats

Energy Management, Regulation and shore competitor to the concrete mat. and run the risk of not maintaining

Enforcement (BOEMRE). Water depth, Bonorden described the standard sling their shape.

install cost and diver effciency are bag as a burlap bag that contains a 3:1 In direct contrast, concrete mats are

Pipelines typically some of the major factors in mixture of concrete and cement that recognized throughout the industry determining if a 9-in. or 12-in. mat hardens under water. Multiple bags are as stable, versatile, and easy to apply. would be the most effective. typically arranged in pallet-sized form After risk assessments have been

Concrete mats can also be tagged for deployment. performed and any necessary type of with information such as pipeline While the usage of sand or concrete permits obtained, in most cases, the number, mat number, contact details, bags somewhat overlap with that mats are transported to the pipeline, and location, so that in the event a mat of concrete mats – they, too, count where teams of divers and/or remotely is moved, the fnder is alerted to return abandonment, trenching, capping and operated vehicles (ROVs) are ready to the mat to its proper owner or loca- spanning among their uses – some assist. The crane operator negotiates tion as quickly as possible, so that the projects present obstacles that exclude the mats into fnal position with guid- pipeline affected can be checked and sling bags as a viable option. David ance from the diver or ROV supervi- tested if needed. Flannery, in business development sor. Once settled, quick-release frames

Premier Concrete regional engineer – Americas at Deepwater Corrosion are commonly implemented to allow

Patrick Bonorden explained that these Services, explains that while sand bags the divers to detach the load from the concrete mats offer a low-cost, perma- are very cost-effective, depending on crane. nent solution to several of the issues the project or pipeline placement, it “You use the mat because it’s one greatest affecting the industry: perma- is the deployment that can sometimes piece, and it’s articulated to do what it nent pipeline protection and environ- present issues. There can be more needs to do,” Premier’s Bonorden said. mental stability. guesswork involved in their placement Perhaps the most famous example “The predominant technology is the over the pipeline than with concrete of how critical concrete mats can be to mats; they’re generally used across the mats, leaving more room for error. the industry was immediately follow- board,” he said. “With sand bags, it’s kind of an art ing the Deepwater Horizon oil spill in form; with mats, it’s more obvious 2010. BP used ROVs to build a subsea how they’re applied,” he continued. staging area with Submar’s mats.

Alternate protection

Depending on the project or pipeline, “They’re very stable, both dimension- Roberts explained that BP needed to be the protection these mats provide pipe- ally and against the environment.” able to immediately deploy equipment lines are among the industry’s best. Then, should the need for removal to assess and address the situation.

The technology can be employed for a arise, as in the case of a pipeline This concrete mat platform was a hold- host of situations, including rig pads, inspection, sling bags must be removed ing ground for the underwater tools capping, abandonment and separation. – and replaced – one by one. The bags and equipment necessary for quick access and dispatch to different areas.

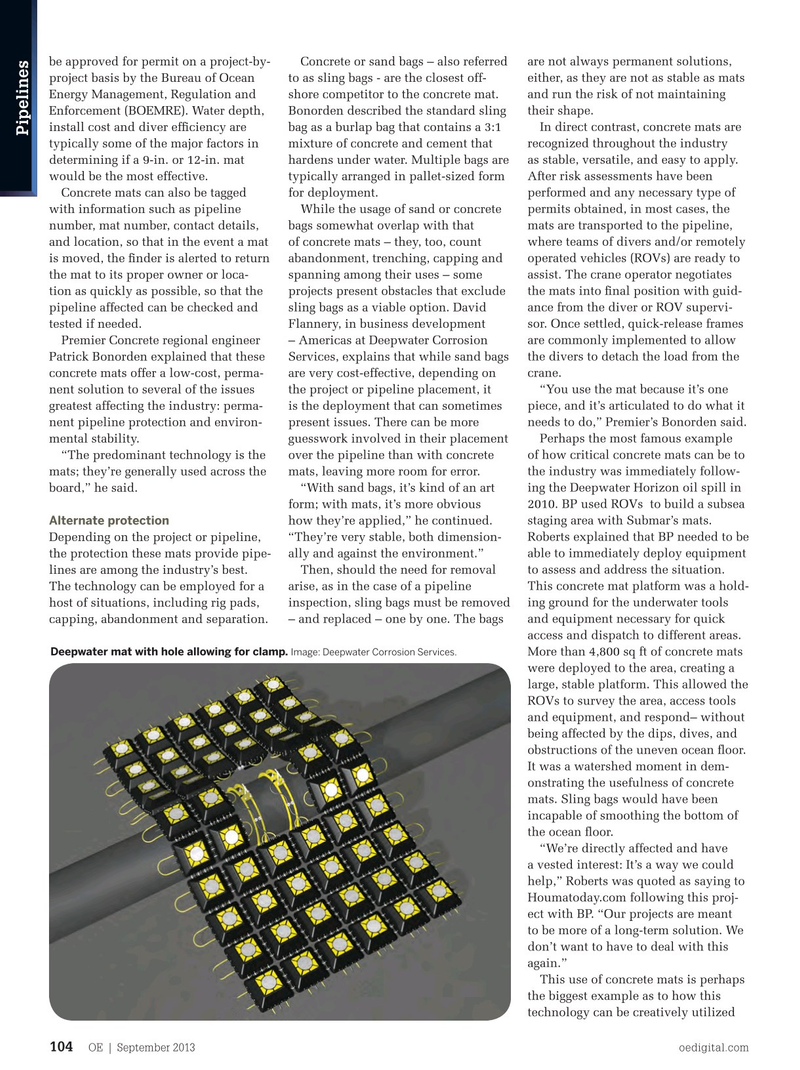

Deepwater mat with hole allowing for clamp. Image: Deepwater Corrosion Services.

More than 4,800 sq ft of concrete mats were deployed to the area, creating a large, stable platform. This allowed the

ROVs to survey the area, access tools and equipment, and respond– without being affected by the dips, dives, and obstructions of the uneven ocean foor.

It was a watershed moment in dem- onstrating the usefulness of concrete mats. Sling bags would have been incapable of smoothing the bottom of the ocean foor. “We’re directly affected and have a vested interest: It’s a way we could help,” Roberts was quoted as saying to

Houmatoday.com following this proj- ect with BP. “Our projects are meant to be more of a long-term solution. We don’t want to have to deal with this again.”

This use of concrete mats is perhaps the biggest example as to how this technology can be creatively utilized

OE | September 2013 oedigital.com 104 102_OE0913_Pipelines1_Concrete.indd 104 8/17/13 6:39 PM

101

101

103

103