Page 40: of Offshore Engineer Magazine (Sep/Oct 2013)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2013 Offshore Engineer Magazine

Ensco 87 rig was operating in Three workers, all from the 218ft of water. Workers were Philippines, employed by Grand able to activate the blowout Isles Shipyard were killed. Two preventer to stop gas from died during the incident and were

HSEQ fowing to the surface. later found near the accident site. A

Although no bubbling was third worker, a welder, passed away seen that would have indicated due to complications from major a seafoor breach, gas had burn injuries on November 23.

intermittently been detected In November, John Hoffman, CEO on the surface at the well- of Black Elk Energy, told Houston head indicating slight seepage TV station KTRK that workers Image: Courtesy of the US Coast Guard.

through surface connections, had used a cutting torch to cut a

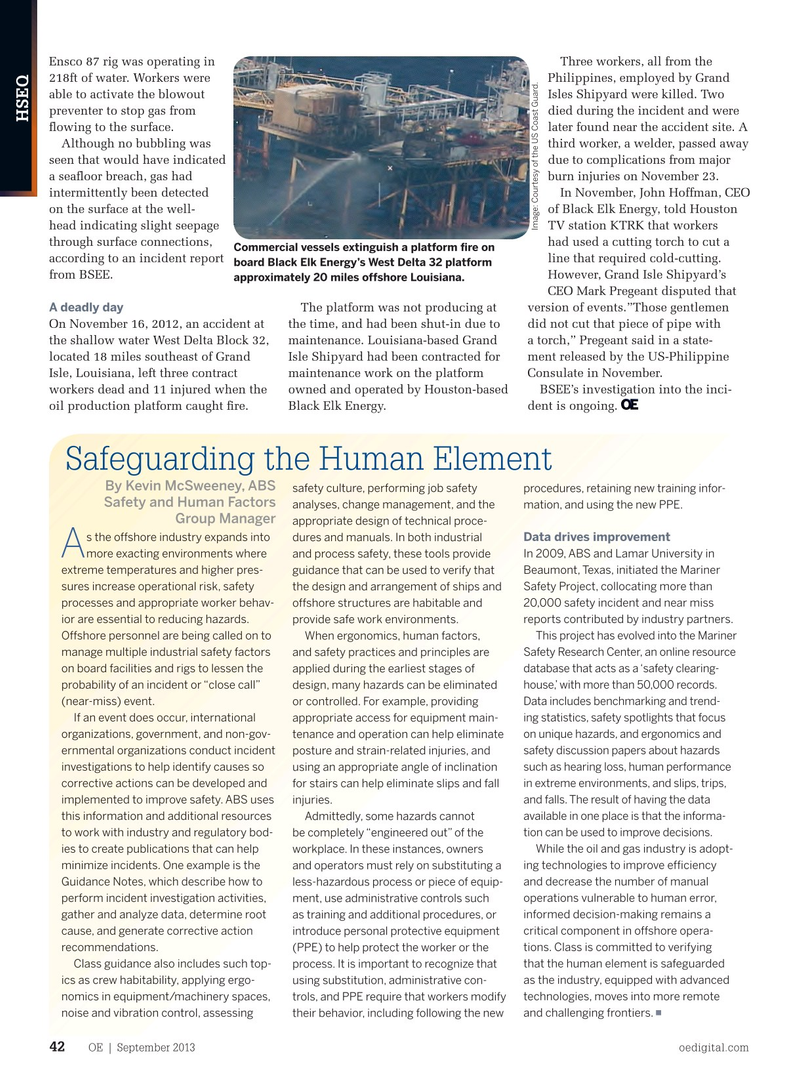

Commercial vessels extinguish a platform fre on according to an incident report line that required cold-cutting. board Black Elk Energy’s West Delta 32 platform from BSEE. However, Grand Isle Shipyard’s approximately 20 miles offshore Louisiana.

CEO Mark Pregeant disputed that

A deadly day The platform was not producing at version of events.”Those gentlemen

On November 16, 2012, an accident at the time, and had been shut-in due to did not cut that piece of pipe with the shallow water West Delta Block 32, maintenance. Louisiana-based Grand a torch,” Pregeant said in a state- located 18 miles southeast of Grand Isle Shipyard had been contracted for ment released by the US-Philippine

Isle, Louisiana, left three contract maintenance work on the platform Consulate in November.

workers dead and 11 injured when the owned and operated by Houston-based BSEE’s investigation into the inci- oil production platform caught fre. Black Elk Energy. dent is ongoing.

Safeguarding the Human Element

By Kevin McSweeney, ABS safety culture, performing job safety procedures, retaining new training infor-

Safety and Human Factors analyses, change management, and the mation, and using the new PPE.

Group Manager appropriate design of technical proce- s the offshore industry expands into dures and manuals. In both industrial

Data drives improvement

A more exacting environments where and process safety, these tools provide In 2009, ABS and Lamar University in extreme temperatures and higher pres- guidance that can be used to verify that Beaumont, Texas, initiated the Mariner sures increase operational risk, safety the design and arrangement of ships and Safety Project, collocating more than processes and appropriate worker behav- offshore structures are habitable and 20,000 safety incident and near miss ior are essential to reducing hazards. provide safe work environments. reports contributed by industry partners.

This project has evolved into the Mariner

Offshore personnel are being called on to When ergonomics, human factors,

Safety Research Center, an online resource manage multiple industrial safety factors and safety practices and principles are database that acts as a ‘safety clearing- on board facilities and rigs to lessen the applied during the earliest stages of house,’ with more than 50,000 records. probability of an incident or “close call” design, many hazards can be eliminated

Data includes benchmarking and trend- (near-miss) event. or controlled. For example, providing ing statistics, safety spotlights that focus

If an event does occur, international appropriate access for equipment main- on unique hazards, and ergonomics and organizations, government, and non-gov- tenance and operation can help eliminate safety discussion papers about hazards ernmental organizations conduct incident posture and strain-related injuries, and such as hearing loss, human performance investigations to help identify causes so using an appropriate angle of inclination in extreme environments, and slips, trips, corrective actions can be developed and for stairs can help eliminate slips and fall and falls. The result of having the data implemented to improve safety. ABS uses injuries. available in one place is that the informa- this information and additional resources Admittedly, some hazards cannot tion can be used to improve decisions.

to work with industry and regulatory bod- be completely “engineered out” of the ies to create publications that can help workplace. In these instances, owners While the oil and gas industry is adopt- minimize incidents. One example is the and operators must rely on substituting a ing technologies to improve effciency

Guidance Notes, which describe how to less-hazardous process or piece of equip- and decrease the number of manual perform incident investigation activities, ment, use administrative controls such operations vulnerable to human error, gather and analyze data, determine root as training and additional procedures, or informed decision-making remains a cause, and generate corrective action introduce personal protective equipment critical component in offshore opera- recommendations. (PPE) to help protect the worker or the tions. Class is committed to verifying

Class guidance also includes such top- process. It is important to recognize that that the human element is safeguarded ics as crew habitability, applying ergo- using substitution, administrative con- as the industry, equipped with advanced nomics in equipment/machinery spaces, trols, and PPE require that workers modify technologies, moves into more remote n noise and vibration control, assessing their behavior, including following the new and challenging frontiers.

OE | September 2013 oedigital.com 42 040_OE0913_HSEQ2_NOIA.indd 42 8/18/13 8:20 PM

39

39

41

41