Page 69: of Offshore Engineer Magazine (Oct/Nov 2013)

Read this page in Pdf, Flash or Html5 edition of Oct/Nov 2013 Offshore Engineer Magazine

Gulf of Mexico % WI) with six other partners. submersible is similar in design to for the GOM. It is for Walter Oil &

Chevron Big Foot TLP – This unit LLOG’s Who Dat FPS, although the Gas’ Coelacanth project, which

Delta House unit is approximately is in Ewing Bank 834 in just under will be installed in Walker Ridge (WR) 29 in about 5,300 ft. of water and is 40% larger in size and throughput 1200ft of water. This water depth capacity. The FPS will be installed would not be unusual if developed expected to come online in 2014. in Mississippi Canyon (MS) 254 in with a foating production system,

The hull is an extended TLP with a production capacity of 75,000 bo/d 4500ft of water. The facility has a but Walter has committed to build payload capacity of 9300 tons and the third-largest, fxed platform in the and 25 MMcfd. Total expected project production capacity of 80,000bo/d, world. Those in greater water depths cost is over US$4 billion. The TLP will include a platform rig on deck, using 200MMcfd, and 40,000bw/d with are Shell’s Bullwinkle, installed in two high-pressure drilling risers, and peaking capacity up to 100,000bo/d 1353ft of water in 1988, and BP’s and 240MMcfd. The hull is currently Pompano, which was installed in has capacity for 15 production/injec- tion top-tensioned risers. Chevron being built at Hyundai Heavy indus- 1994 in 1290ft of water. Both are is operator (60% WI) with partners tries in South Korea and the topsides also located in the GOM. Walter

Statoil (27.5%) and Marubeni Oil and are being fabricated at Kiewit. Subsea decided to use a fxed platform with

Gas (12.5%).

wells will be tied back from MC 255, surface wells and a platform rig due

Chevron Jack/St. Malo FPS – This

MS 300, and MS 431, and the FPS is to concerns over fow assurance semisubmersible foating production designed to accept production from with subsea tiebacks, the high cost system will be installed in WR 758 other subsea tiebacks in the future. and limited availability of moored in about 7000ft of water. The overall

The hull is designed to accommodate drilling rigs, and the medium size development cost is estimated at $7.5 up to 20 steel-catenary risers (up topsides of about 3500 tons having a billion with production ramping up in to nine felds with dual fowlines). capacity of 30,000bo/d, 15,000bw/d 2014. The FPS has a production capac-

First oil is expected in the frst half and 60MMcfd. The jacket and top- ity of 170,000bo/d and 42.5MMcfd of 2015. LLOG is the operator and sides will be built in the Gulf Island with provisions for future water injec- partners are Ridgewood Energy, Fabrication facility at Ingleside, Texas, tion of 200,000b/d. It will produce

Red Willow Offshore LLC, Calypso which was originally developed for from three felds: Jack (WR 758, WR

Exploration, Deep Gulf Energy II, the Bullwinkle project. The jacket is a 759), St. Malo (WR 678) and Julia (WR

Houston Energy, and ILX Holdings massive 31,000 tons.

584, WR 627, WR 628, WR 540, WR There are a number of other projects

LLC, an affliate of Riverstone 583) using multiple subsea centers. moving forward in the GOM, but it

Holdings LLC.

Chevron is operator of Jack (50% is unique to see this many deepwater

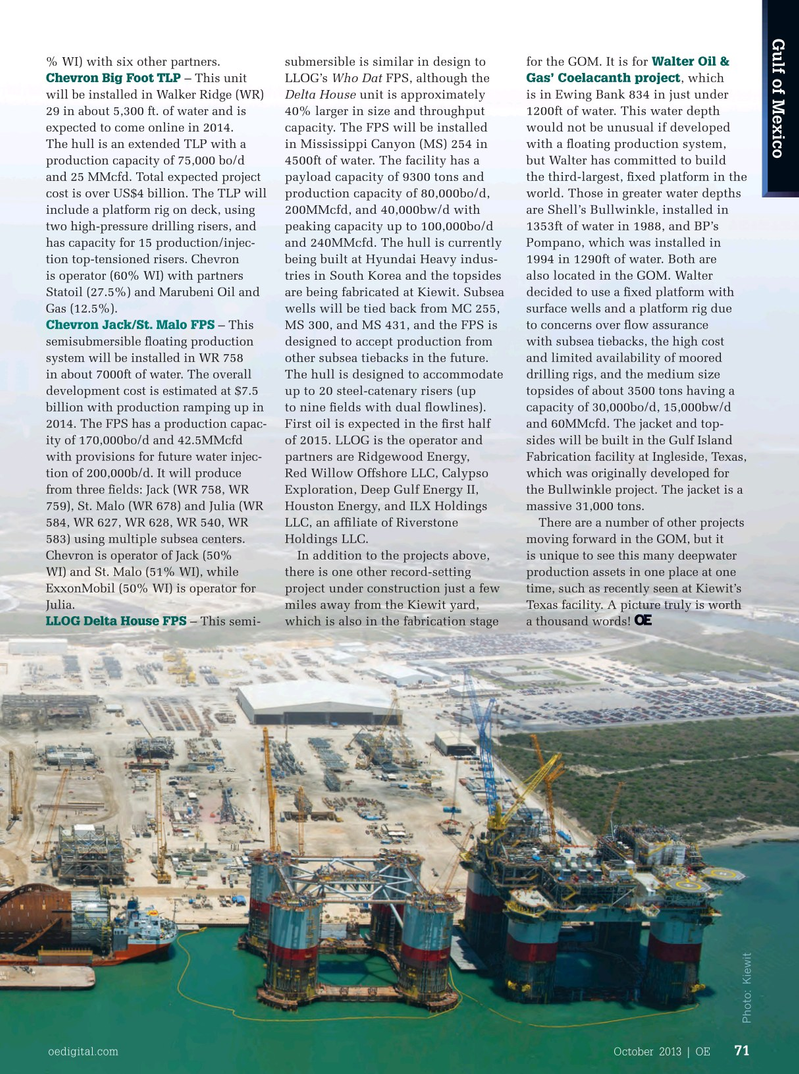

In addition to the projects above,

WI) and St. Malo (51% WI), while production assets in one place at one there is one other record-setting

ExxonMobil (50% WI) is operator for time, such as recently seen at Kiewit’s project under construction just a few

Julia. Texas facility. A picture truly is worth miles away from the Kiewit yard,

LLOG Delta House FPS – This a thousand words! semi- which is also in the fabrication stage

Photo: Kiewit oedigital.com October 2013 | OE 71 1013OE_Geofocus4_Kiewitt.indd 71 9/29/13 10:26 PM

68

68

70

70