Page 22: of Offshore Engineer Magazine (Nov/Dec 2013)

Read this page in Pdf, Flash or Html5 edition of Nov/Dec 2013 Offshore Engineer Magazine

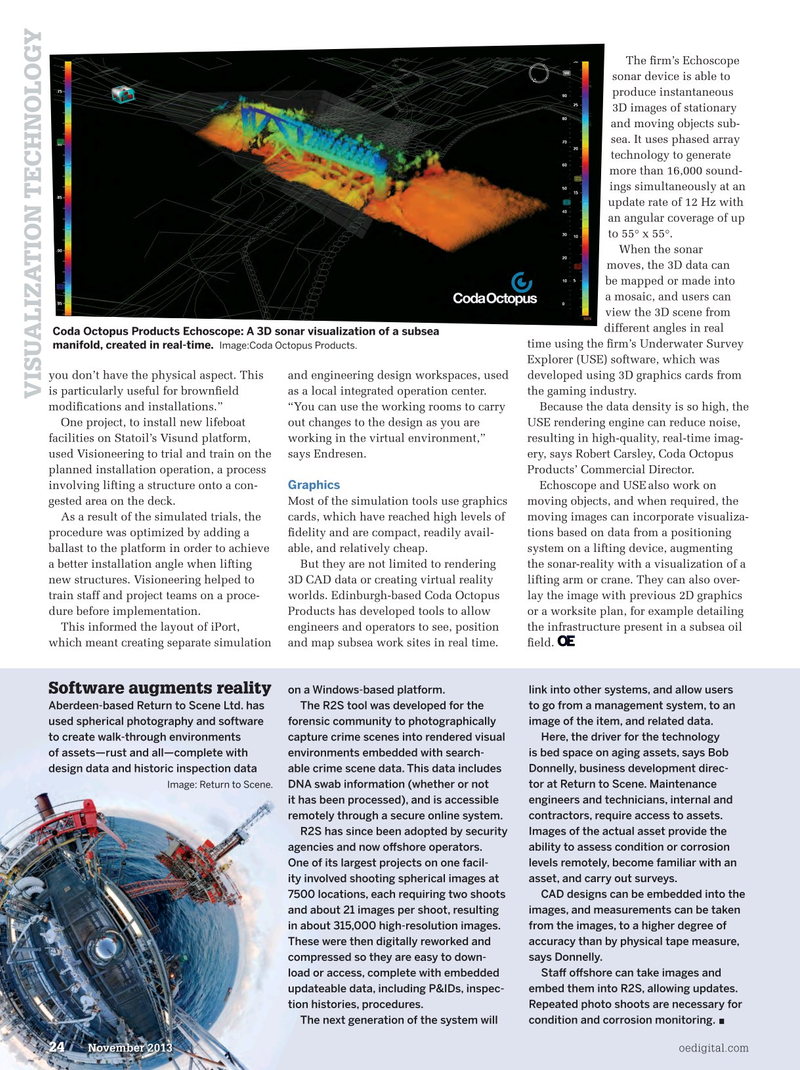

The frm’s Echoscope sonar device is able to produce instantaneous 3D images of stationary and moving objects sub- sea. It uses phased array technology to generate more than 16,000 sound- ings simultaneously at an update rate of 12 Hz with an angular coverage of up to 55° x 55°.

When the sonar moves, the 3D data can be mapped or made into a mosaic, and users can view the 3D scene from different angles in real

Coda Octopus Products Echoscope: A 3D sonar visualization of a subsea time using the frm’s Underwater Survey manifold, created in real-time. Image:Coda Octopus Products.

Explorer (USE) software, which was you don’t have the physical aspect. This and engineering design workspaces, used developed using 3D graphics cards from is particularly useful for brownfeld as a local integrated operation center. the gaming industry.

VISUALIZATION TECHNOLOGY modifcations and installations.” “You can use the working rooms to carry Because the data density is so high, the

One project, to install new lifeboat out changes to the design as you are USE rendering engine can reduce noise, facilities on Statoil’s Visund platform, working in the virtual environment,” resulting in high-quality, real-time imag- used Visioneering to trial and train on the says Endresen. ery, says Robert Carsley, Coda Octopus planned installation operation, a process Products’ Commercial Director.

Graphics involving lifting a structure onto a con- Echoscope and USEalso work on gested area on the deck. Most of the simulation tools use graphics moving objects, and when required, the

As a result of the simulated trials, the cards, which have reached high levels of moving images can incorporate visualiza- procedure was optimized by adding a fdelity and are compact, readily avail- tions based on data from a positioning ballast to the platform in order to achieve able, and relatively cheap. system on a lifting device, augmenting a better installation angle when lifting But they are not limited to rendering the sonar-reality with a visualization of a new structures. Visioneering helped to 3D CAD data or creating virtual reality lifting arm or crane. They can also over- train staff and project teams on a proce- worlds. Edinburgh-based Coda Octopus lay the image with previous 2D graphics dure before implementation. Products has developed tools to allow or a worksite plan, for example detailing

This informed the layout of iPort, engineers and operators to see, position the infrastructure present in a subsea oil which meant creating separate simulation and map subsea work sites in real time. feld.

Software augments reality on a Windows-based platform. link into other systems, and allow users

Aberdeen-based Return to Scene Ltd. has The R2S tool was developed for the to go from a management system, to an used spherical photography and software forensic community to photographically image of the item, and related data. to create walk-through environments capture crime scenes into rendered visual Here, the driver for the technology of assets—rust and all—complete with environments embedded with search- is bed space on aging assets, says Bob design data and historic inspection data able crime scene data. This data includes Donnelly, business development direc-

DNA swab information (whether or not tor at Return to Scene. Maintenance

Image: Return to Scene.

it has been processed), and is accessible engineers and technicians, internal and remotely through a secure online system. contractors, require access to assets.

R2S has since been adopted by security Images of the actual asset provide the agencies and now ofshore operators. ability to assess condition or corrosion

One of its largest projects on one facil- levels remotely, become familiar with an ity involved shooting spherical images at asset, and carry out surveys. 7500 locations, each requiring two shoots CAD designs can be embedded into the and about 21 images per shoot, resulting images, and measurements can be taken in about 315,000 high-resolution images. from the images, to a higher degree of

These were then digitally reworked and accuracy than by physical tape measure, compressed so they are easy to down- says Donnelly. load or access, complete with embedded Staf ofshore can take images and updateable data, including P&IDs, inspec- embed them into R2S, allowing updates. tion histories, procedures. Repeated photo shoots are necessary for

The next generation of the system will condition and corrosion monitoring. •

November 2013 oedigital.com 24 022_OE1113_Vis1.indd 24 10/28/13 3:32 AM

21

21

23

23