Page 34: of Offshore Engineer Magazine (Nov/Dec 2013)

Read this page in Pdf, Flash or Html5 edition of Nov/Dec 2013 Offshore Engineer Magazine

The high intensity in onshore wells suggests the industry is more prepared to take risk in trying new techniques or technologies in this relatively inexpen- sive environment, although the technical

Production success rate was the same as on offshore

NUIs, at 66%.

Thus, onshore wells provide fertile ground for de-risking new types of intervention techniques prior to imple- menting them in the more costly offshore environment, according to WIEN.

Unit costs

Ranking the different types of interven- tion in the order of unit costs, water

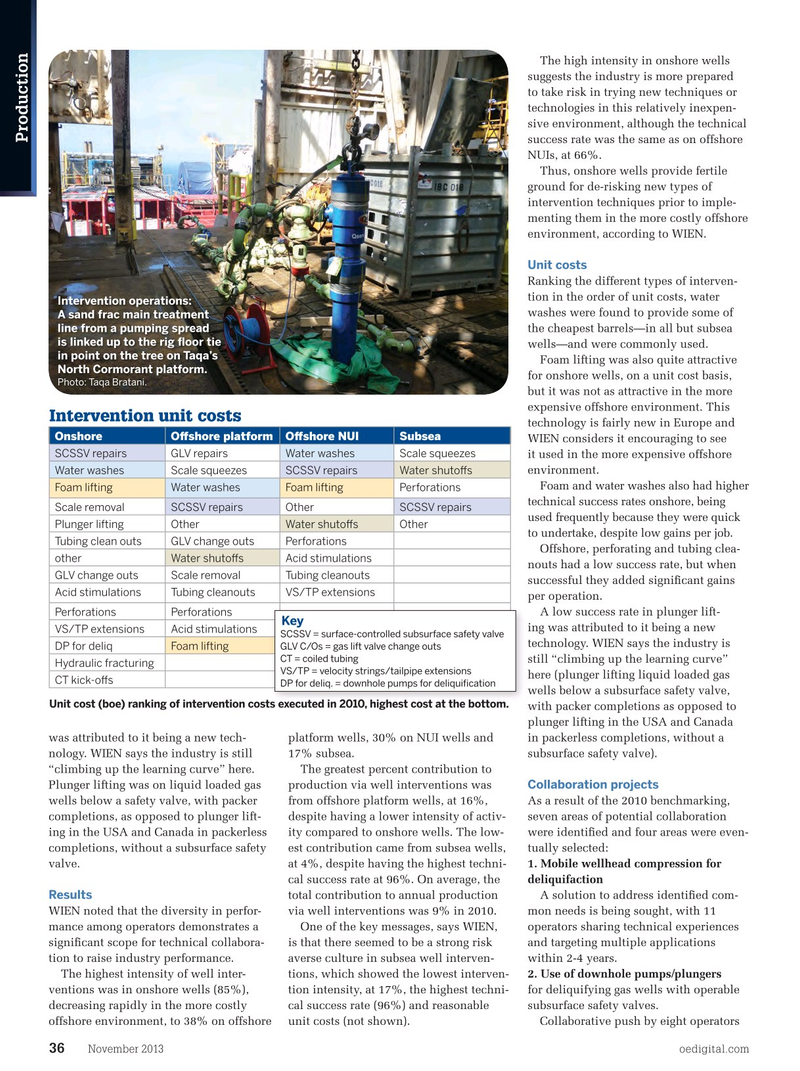

Intervention operations: washes were found to provide some of

A sand frac main treatment the cheapest barrels—in all but subsea line from a pumping spread is linked up to the rig foor tie wells—and were commonly used. in point on the tree on Taqa’s

Foam lifting was also quite attractive

North Cormorant platform. for onshore wells, on a unit cost basis,

Photo: Taqa Bratani.

but it was not as attractive in the more expensive offshore environment. This

Intervention unit costs technology is fairly new in Europe and

Onshore Ofshore platformOfshore NUI Subsea

WIEN considers it encouraging to see

SCSSV repairs GLV repairs Water washesScale squeezes it used in the more expensive offshore environment.

Water washesScale squeezes SCSSV repairs Water shutofs

Foam and water washes also had higher

Foam lifting Water washesFoam lifting Perforations technical success rates onshore, being

Scale removal SCSSV repairs Other SCSSV repairs used frequently because they were quick

Plunger liftingOther Water shutofsOther to undertake, despite low gains per job.

Tubing clean outsGLV change outsPerforations

Offshore, perforating and tubing clea- other Water shutofsAcid stimulations nouts had a low success rate, but when

GLV change outsScale removalTubing cleanouts successful they added signifcant gains

Acid stimulationsTubing cleanoutsVS/TP extensions per operation.

A low success rate in plunger lift-

PerforationsPerforations

Key ing was attributed to it being a new

VS/TP extensionsAcid stimulations

SCSSV = surface-controlled subsurface safety valve technology. WIEN says the industry is

GLV C/Os = gas lift valve change outs

DP for deliq Foam lifting

CT = coiled tubing still “climbing up the learning curve”

Hydraulic fracturing

VS/TP = velocity strings/tailpipe extensions here (plunger lifting liquid loaded gas

CT kick-ofs

DP for deliq. = downhole pumps for deliquifcation wells below a subsurface safety valve,

Unit cost (boe) ranking of intervention costs executed in 2010, highest cost at the bottom. with packer completions as opposed to plunger lifting in the USA and Canada was attributed to it being a new tech- platform wells, 30% on NUI wells and in packerless completions, without a nology. WIEN says the industry is still 17% subsea. subsurface safety valve). “climbing up the learning curve” here. The greatest percent contribution to

Collaboration projects

Plunger lifting was on liquid loaded gas production via well interventions was wells below a safety valve, with packer from offshore platform wells, at 16%, As a result of the 2010 benchmarking, completions, as opposed to plunger lift- despite having a lower intensity of activ- seven areas of potential collaboration ing in the USA and Canada in packerless ity compared to onshore wells. The low- were identifed and four areas were even- completions, without a subsurface safety est contribution came from subsea wells, tually selected: valve. at 4%, despite having the highest techni- 1. Mobile wellhead compression for cal success rate at 96%. On average, the deliquifaction

Results total contribution to annual production A solution to address identifed com-

WIEN noted that the diversity in perfor- via well interventions was 9% in 2010. mon needs is being sought, with 11 mance among operators demonstrates a One of the key messages, says WIEN, operators sharing technical experiences signifcant scope for technical collabora- is that there seemed to be a strong risk and targeting multiple applications tion to raise industry performance. averse culture in subsea well interven- within 2-4 years.

The highest intensity of well inter- tions, which showed the lowest interven- 2. Use of downhole pumps/plungers ventions was in onshore wells (85%), tion intensity, at 17%, the highest techni- for deliquifying gas wells with operable decreasing rapidly in the more costly cal success rate (96%) and reasonable subsurface safety valves.

offshore environment, to 38% on offshore unit costs (not shown). Collaborative push by eight operators

November 2013 oedigital.com 36 034_OE1113_ProdOps1.indd 36 10/28/13 1:37 AM

33

33

35

35