Page 38: of Offshore Engineer Magazine (Dec/Jan 2013)

Read this page in Pdf, Flash or Html5 edition of Dec/Jan 2013 Offshore Engineer Magazine

FPSO

Production technology evolves

Ensuring the structural and loating production storage and standard and base case for the new gen- offoading (FPSO) vessels have eration of very large internal turret sys- marine integrity of foating

F been a part of UK Continental tems, according to a joint BP/SBM paper production installations over

Shelf industry for more than two presented by Philippe Lavagna, SBM decades. In that time, there have been Offshore’s project engineering – moor- their lifetime was the overall incidents with both mooring systems and ing EPM manager. The paper compared theme of a technical session at hull structural integrity that required the main features of the Schiehallion, corrective action. onstream in 1998, with the turret moor-

Ofshore Europe in Aberdeen this ing system of the vessel due to replace fall. Meg Chesshyre reports.

Advances in turret design it, the Quad 204, being built by Hyundai

The Quad 204 turret design sets a new Heavy Industries in South Korea. Both

FPSOs are supplied by SBM Offshore,

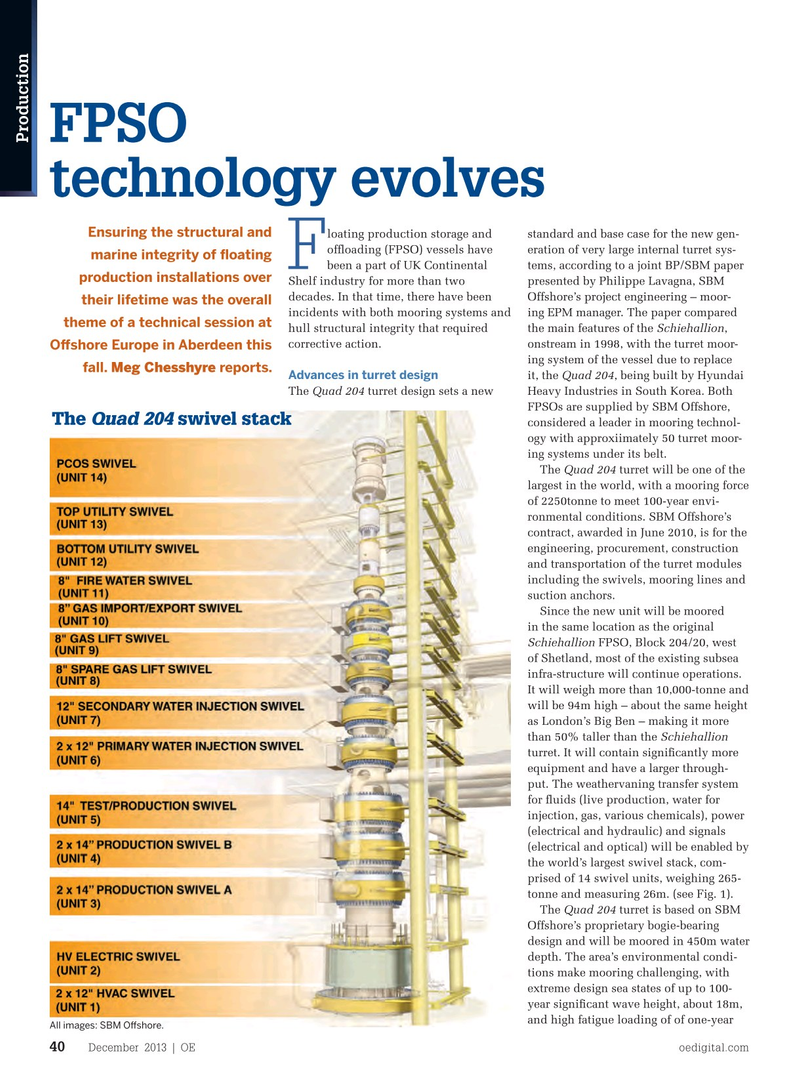

The swivel stack Quad 204 considered a leader in mooring technol- ogy with approxiimately 50 turret moor- ing systems under its belt.

The Quad 204 turret will be one of the largest in the world, with a mooring force of 2250tonne to meet 100-year envi- ronmental conditions. SBM Offshore’s contract, awarded in June 2010, is for the engineering, procurement, construction and transportation of the turret modules including the swivels, mooring lines and suction anchors.

Since the new unit will be moored in the same location as the original

Schiehallion FPSO, Block 204/20, west of Shetland, most of the existing subsea infra-structure will continue operations.

It will weigh more than 10,000-tonne and will be 94m high – about the same height as London’s Big Ben – making it more than 50% taller than the Schiehallion turret. It will contain signifcantly more equipment and have a larger through- put. The weathervaning transfer system for fuids (live production, water for injection, gas, various chemicals), power (electrical and hydraulic) and signals (electrical and optical) will be enabled by the world’s largest swivel stack, com- prised of 14 swivel units, weighing 265- tonne and measuring 26m. (see Fig. 1).

The Quad 204 turret is based on SBM

Offshore’s proprietary bogie-bearing design and will be moored in 450m water depth. The area’s environmental condi- tions make mooring challenging, with extreme design sea states of up to 100- year signifcant wave height, about 18m, and high fatigue loading of of one-year

All images: SBM Ofshore.

December 2013 | OE oedigital.com 40 040_OE1213_ProdOps_StrucIntegrity.indd 40 11/22/13 6:29 PM

37

37

39

39