Page 53: of Offshore Engineer Magazine (Dec/Jan 2013)

Read this page in Pdf, Flash or Html5 edition of Dec/Jan 2013 Offshore Engineer Magazine

Flowlines

There have been attempts to formulate

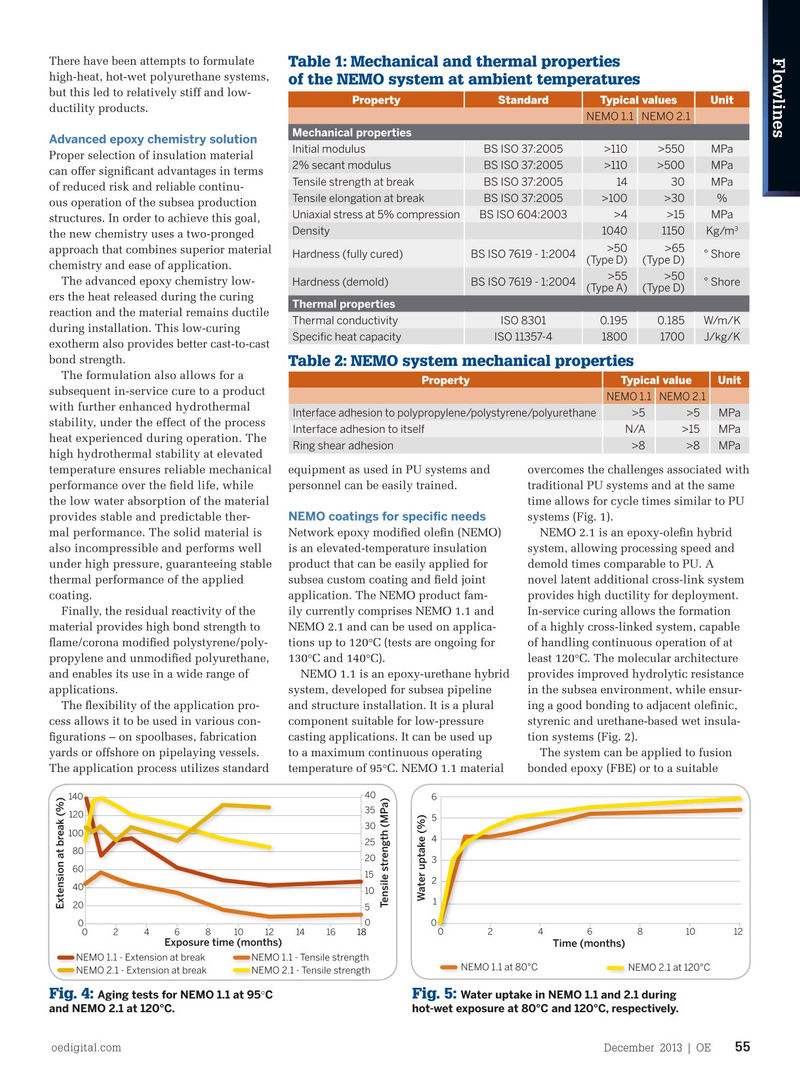

Table 1: Mechanical and thermal properties high-heat, hot-wet polyurethane systems, of the NEMO system at ambient temperatures but this led to relatively stiff and low-

Property StandardTypical valuesUnit ductility products.

NEMO 1.1NEMO 2.1

Mechanical properties

Advanced epoxy chemistry solution

Initial modulus BS ISO 37:2005>110>550 MPa

Proper selection of insulation material 2% secant modulus BS ISO 37:2005>110>500 MPa can offer signifcant advantages in terms

Tensile strength at break BS ISO 37:2005 14 30 MPa of reduced risk and reliable continu-

Tensile elongation at break BS ISO 37:2005>100>30% ous operation of the subsea production

Uniaxial stress at 5% compression BS ISO 604:2003>4>15 MPa structures. In order to achieve this goal, 3

Density 10401150Kg/m the new chemistry uses a two-pronged >50 >65 approach that combines superior material

Hardness (fully cured) BS ISO 7619 - 1:2004 ° Shore (Type D) (Type D) chemistry and ease of application. >55 >50

The advanced epoxy chemistry low-

Hardness (demold) BS ISO 7619 - 1:2004 ° Shore (Type D) (Type A) ers the heat released during the curing

Thermal properties reaction and the material remains ductile

Thermal conductivity ISO 83010.1950.185 W/m/K during installation. This low-curing

Specifc heat capacity ISO 11357-41800 1700 J/kg/K exotherm also provides better cast-to-cast bond strength.

Table 2: NEMO system mechanical properties

The formulation also allows for a

Property Typical valueUnit subsequent in-service cure to a product

NEMO 1.1 NEMO 2.1 with further enhanced hydrothermal >5>5 MPaInterface adhesion to polypropylene/polystyrene/polyurethane stability, under the effect of the process

Interface adhesion to itself N/A >15 MPa heat experienced during operation. The

Ring shear adhesion >8>8 MPa high hydrothermal stability at elevated equipment as used in PU systems and overcomes the challenges associated with temperature ensures reliable mechanical personnel can be easily trained. traditional PU systems and at the same performance over the feld life, while the low water absorption of the material time allows for cycle times similar to PU

NEMO coatings for specifc needs provides stable and predictable ther- systems (Fig. 1).

mal performance. The solid material is

Network epoxy modifed olefn (NEMO) NEMO 2.1 is an epoxy-olefn hybrid also incompressible and performs well is an elevated-temperature insulation system, allowing processing speed and under high pressure, guaranteeing stable product that can be easily applied for demold times comparable to PU. A subsea custom coating and feld joint novel latent additional cross-link system thermal performance of the applied application. The NEMO product fam- provides high ductility for deployment. coating.

Finally, the residual reactivity of the ily currently comprises NEMO 1.1 and In-service curing allows the formation material provides high bond strength to NEMO 2.1 and can be used on applica- of a highly cross-linked system, capable fame/corona modifed polystyrene/poly- tions up to 120°C (tests are ongoing for of handling continuous operation of at propylene and unmodifed polyurethane, 130°C and 140°C). least 120°C. The molecular architecture and enables its use in a wide range of NEMO 1.1 is an epoxy-urethane hybrid provides improved hydrolytic resistance applications. system, developed for subsea pipeline in the subsea environment, while ensur-

The fexibility of the application pro- and structure installation. It is a plural ing a good bonding to adjacent olefnic, cess allows it to be used in various con- component suitable for low-pressure styrenic and urethane-based wet insula- fgurations – on spoolbases, fabrication casting applications. It can be used up tion systems (Fig. 2). yards or offshore on pipelaying vessels. to a maximum continuous operating The system can be applied to fusion

The application process utilizes standard temperature of 95°C. NEMO 1.1 material bonded epoxy (FBE) or to a suitable 40 140 6 35 120 5 30 100 4 25 80 20 3 60 15 2 40 10

Water uptake (%) 1

Tensile strength (MPa) 20

Extension at break (%) 5 0 02 46 8 10 12 0 0 02468 10 12 14 16 18

Exposure time (months)

Time (months)

NEMO 1.1 - Extension at break NEMO 1.1 - Tensile strength

NEMO 1.1 at 80°C NEMO 2.1 at 120°C

NEMO 2.1 - Extension at break NEMO 2.1 - Tensile strength

Aging tests for NEMO 1.1 at 95°C Water uptake in NEMO 1.1 and 2.1 during

Fig. 4: Fig. 5: and NEMO 2.1 at 120°C. hot-wet exposure at 80°C and 120°C, respectively. oedigital.com December 2013 | OE 55 054_OE1213_Pipelines3_Bredero_v2.indd 55 11/22/13 7:20 PM

52

52

54

54