Page 45: of Offshore Engineer Magazine (Jan/Feb 2014)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2014 Offshore Engineer Magazine

Production

Petrobras a major challenge. The size of the

Schlumberger has 150,000 mobile

Nathalia da Silva Sena, technical con- assets, 2,500 facilities, and 125 research challenge is enormous, but so is the sultant, Petrobras, presented some of the and engineering centers. Additionally, bene? t.” challenges Petrobras has to deal with in the company makes approximately

The NCS and Brazil terms of meeting E&P demands. With 80,000 shipments per month, conducts continued growth in both the Santos and 150,000 transactions per day, and works Bjornar Aas, CEO X2X Maritime AS, used

Using RFID technology

Campos basins, Petrobras has to meet with 80,000 suppliers, according to data his presentation to compare Brazil’s off- both long-distance and infrastructure supplied by Faria at OTC Brazil. shore challenges to that of the Norwegian challenges, all the while deciding how to “We are tagging those 150,000 high Continental Shelf (NCS). “There is a to improve offshore logistics best utilize the equipment the national value assets. We know when they are major lack of supply chain visibility in player already has. Petrobras transports producing, when they are of? ine, produc- the offshore logistics at the NCS,” Aas 93,000 passengers per month using 155 ing revenue, down for parts, or not per- says. “This leads to inef? ciency, lack of

A stainless steel indenti? cation plate, and a drill pipe tag ? tted with RFID. helicopters, da Silva Sena says. forming to standard,” Faria says. “This is control, and has a negative impact on

Photos courtesy of Trac ID Systems AS.

“Platforms and oil rigs are far from the a massive effort, worldwide.” both cost and HSE.” coast,” da Silva Sena says. Petrobras is in To do all these transactions, The logistical challenges (in Brazil) are need of both bigger helicopters and boats, Schlumberger is backed by 800 IT con- basically quite similar to NCS, he said. which are spread, causing dif? culties, nected wellsite units, and 27 peta? ops of The operators’ goals are basically simi- “Barcodes are very accurate. On the she says. Another challenge is infrastruc- computing power, Faria says. lar. The size of (Petrobras’) operations other end of the spectrum, GPS relies on ture. “In the Campos, we don’t have a For some assets, Schlumberger deploys are larger, but the savings and bene? ts satellites and depending on what kind of lot of available infrastructure to support GPS for tracking that is intertwined should be larger.

user you are, you can get accuracy down activities. In [the] north and northeast, with a ? eet management system, Faria In 2007, Aas noted, the Norwegian to 1m. It can tell you what side of the it is dif? cult to get [it].” Da Silva Sena says. “For those high-dollar, high-risk Oil and Gas Association (formely OLF) street you are. The difference between says Petrobras is currently working on operations, we deploy more sophisticated came together to issue guidelines regard- barcodes and RFID, barcodes read one at projects to improve these issues. technologies.” ing RFID technology implementation.

Faria says that, with regards to a time; RFID is a class of technology that Guideline No. 112 (Part 1-9) dictated

Schlumberger integrating all this new technology into allows you to read multiple sets of data. what kind of RFID equipment a supplier

Schlumberger’s business, the hard-

You can change information.” should choose. “The ? rst step in this his- ware is not the major hindrance. “The

Swerdlow mentioned a case study tory was a common agreement on tech- system’s integration element is signi? - regarding Petrobras’s RFID showroom nology,” Aas says. “The kind of readers, cant. Many companies our size have and innovation center, which has RFID RFID tags, and how can it be packaged, many different systems, many different hardware installed. “The hardware and put on forklift.” ? avors, and different languages,” he shows how goods can be received, Aas said implementing RFID technol- notes. “The hardware is easy compared inspected, and tagged, as well as how ogy shouldn’t be looked at as a one-com-

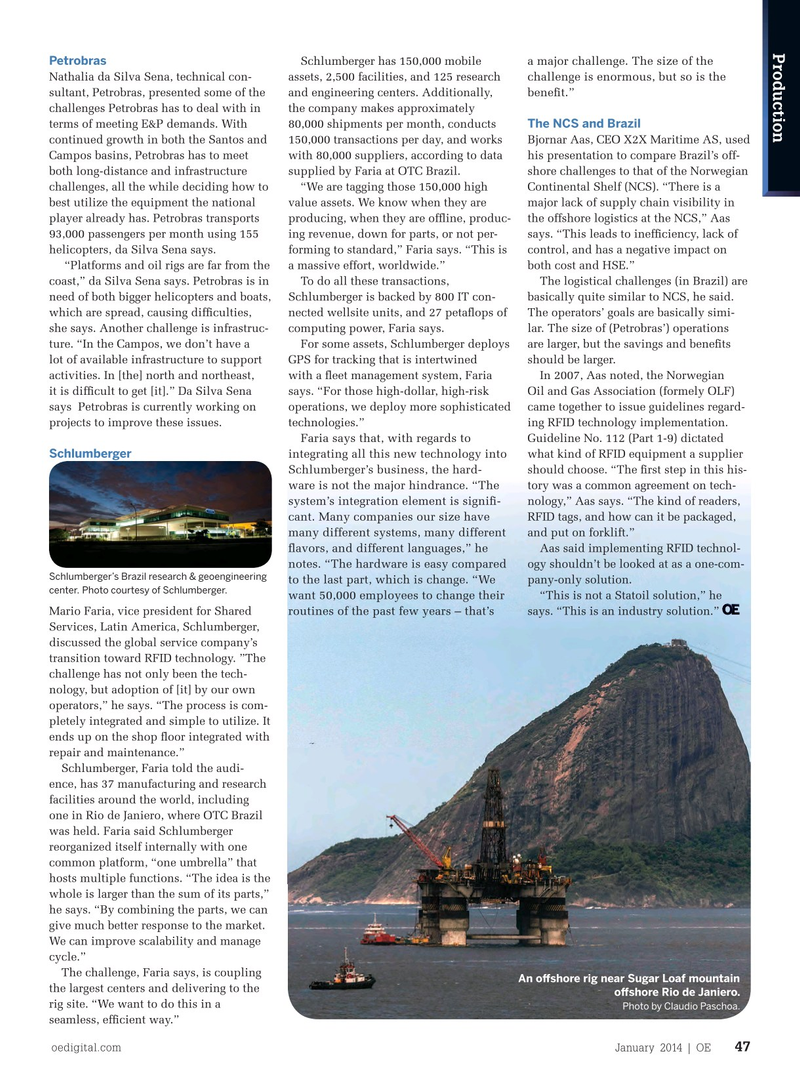

Schlumberger’s Brazil research & geoengineering to the last part, which is change. “We to pick operations for customer orders, pany-only solution.

center. Photo courtesy of Schlumberger.

want 50,000 employees to change their and dispatch,” he says. “The technol- “This is not a Statoil solution,” he routines of the past few years – that’s ogy then is able to search on warehouse Mario Faria, vice president for Shared says. “This is an industry solution.” shelves for where particular orders are. Services, Latin America, Schlumberger,

The showroom brings together in one discussed the global service company’s location, RFID technology and applica- transition toward RFID technology. ”The tions that can be applied throughout challenge has not only been the tech-

Petrobras operations. It provides train- nology, but adoption of [it] by our own ing as well as development and test- operators,” he says. “The process is com- ing of new RFID-enabled processes in pletely integrated and simple to utilize. It

Petrobras’ business.” ends up on the shop ? oor integrated with repair and maintenance.”

Schlumberger, Faria told the audi- ence, has 37 manufacturing and research facilities around the world, including one in Rio de Janiero, where OTC Brazil was held. Faria said Schlumberger reorganized itself internally with one common platform, “one umbrella” that hosts multiple functions. “The idea is the whole is larger than the sum of its parts,” he says. “By combining the parts, we can give much better response to the market.

We can improve scalability and manage cycle.”

The challenge, Faria says, is coupling

An o

44

44

46

46