Page 50: of Offshore Engineer Magazine (Jan/Feb 2014)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2014 Offshore Engineer Magazine

Pipelines

Ultrasonic in-line inspection

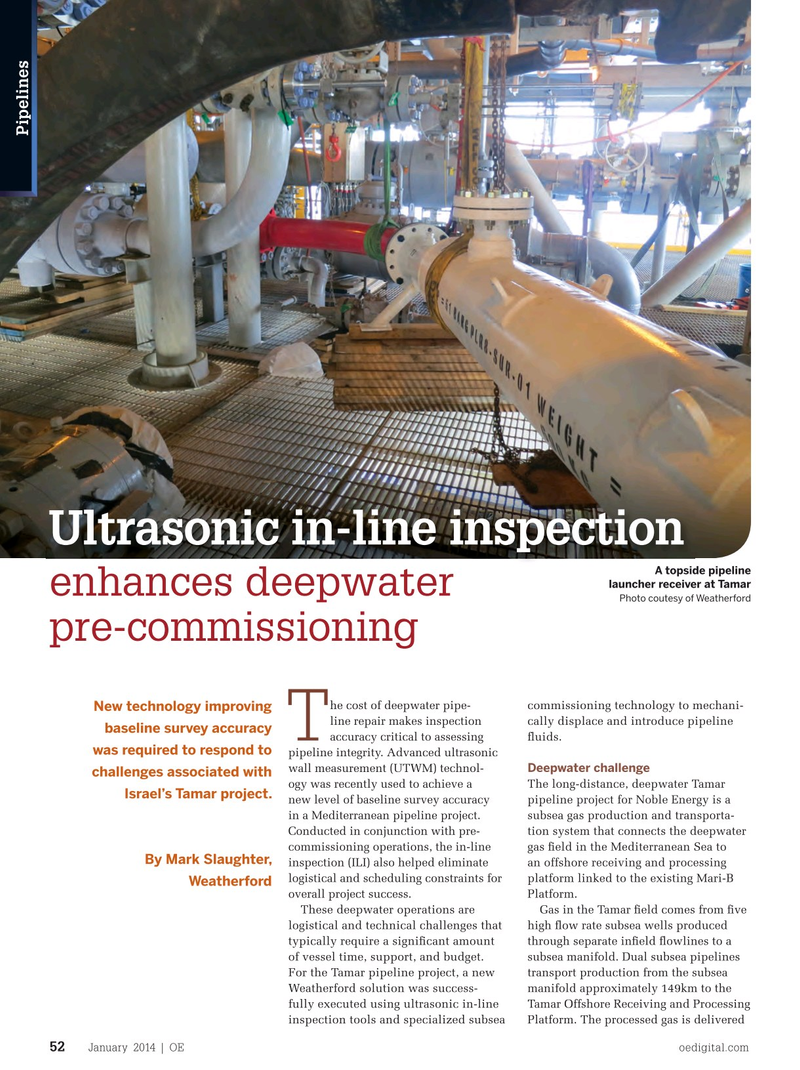

A topside pipeline launcher receiver at Tamar enhances deepwater

Photo coutesy of Weatherford pre-commissioning he cost of deepwater pipe- commissioning technology to mechani-

New technology improving line repair makes inspection cally displace and introduce pipeline baseline survey accuracy

T accuracy critical to assessing ? uids. was required to respond to pipeline integrity. Advanced ultrasonic

Deepwater challenge wall measurement (UTWM) technol- challenges associated with ogy was recently used to achieve a The long-distance, deepwater Tamar

Israel’s Tamar project. new level of baseline survey accuracy pipeline project for Noble Energy is a in a Mediterranean pipeline project. subsea gas production and transporta-

Conducted in conjunction with pre- tion system that connects the deepwater commissioning operations, the in-line gas ? eld in the Mediterranean Sea to

By Mark Slaughter, inspection (ILI) also helped eliminate an offshore receiving and processing logistical and scheduling constraints for platform linked to the existing Mari-B

Weatherford overall project success. Platform.

These deepwater operations are

Gas in the Tamar ? eld comes from ? ve logistical and technical challenges that high ? ow rate subsea wells produced typically require a signi? cant amount through separate in? eld ? owlines to a of vessel time, support, and budget. subsea manifold. Dual subsea pipelines

For the Tamar pipeline project, a new transport production from the subsea

Weatherford solution was success- manifold approximately 149km to the fully executed using ultrasonic in-line

Tamar Offshore Receiving and Processing inspection tools and specialized subsea

Platform. The processed gas is delivered

January 2014 | OE oedigital.com 52 052-OE0114_Pipelines1_Tamar.indd 52 12/19/13 6:27 PM

49

49

51

51