Page 55: of Offshore Engineer Magazine (Jan/Feb 2014)

Read this page in Pdf, Flash or Html5 edition of Jan/Feb 2014 Offshore Engineer Magazine

Pipelines

Germany’s ROSEN Group, speci? cally for Nord Stream. They are: a gauge tool, a cleaning tool, and an in-line inspection tool, which maps potential corrosion and metal loss, as well as the exact curvature of the lines via an inertial navigation system.

Before its use on Nord Stream, each tool underwent extensive testing, which included the inline inspection tool being tested on a similar, shorter, 48-in. pipe-

The gauge tool.

line in Malaysia.

A pig run

The inspection process started on the ? rst pipeline on July 1, 2013. The gauge pig, like all the other pigs, started its run at the Landfall Facilities Russia (LFFR), at Portovaya, by being inserted into the line via a pig launcher.

The gauge tool, at 2.2m-long and weighing 1.5-tonne, is used to detect substantial anomalies of the internal diameter along the pipeline, which may

The cleaning tool.

potentially obstruct the inline inspec- tion tool during its run. The gauge tool’s in front of the tool by sealing discs aluminum plates are designed to detect sized larger than the pipeline’s interior any anomaly starting at 3% (35.5mm or diameter. “Differential pressure is used 1.4-in.). in order to guide an amount of natural

Any protrusion would chip away at gas through the cleaning tool body to the the gauge plate, with the damage later very front where nozzles create a ? ushing analyzed to determine the extent of the effect. This setup is comparable to a pres- potential obstruction. sure washer on a dry basis,” says Nord

The gauge tool took ? ve days to travel Stream.

with the gas ? ow to Germany, where it The cleaning tool run also took ? ve was retrieved. The plates were found days. The tool was then cleaned, with the Arrival of the inline inspection tool at thickness of pipe walls (up to 41mm) to to be undamaged, which indicated that material collected on the run analyzed.

Lubmin, Germany. All images: Courtesy of be analyzed. the pipeline had not experienced any Results from the tool con? rmed the pipe-

ROSEN Inspection Technologies.

The inspection means Nord Stream mechanical impact since construction. line was clean. The amount of the mate- now has baseline data to con? rm the the 1224km offshore section of the rial collected during the internal inspec-

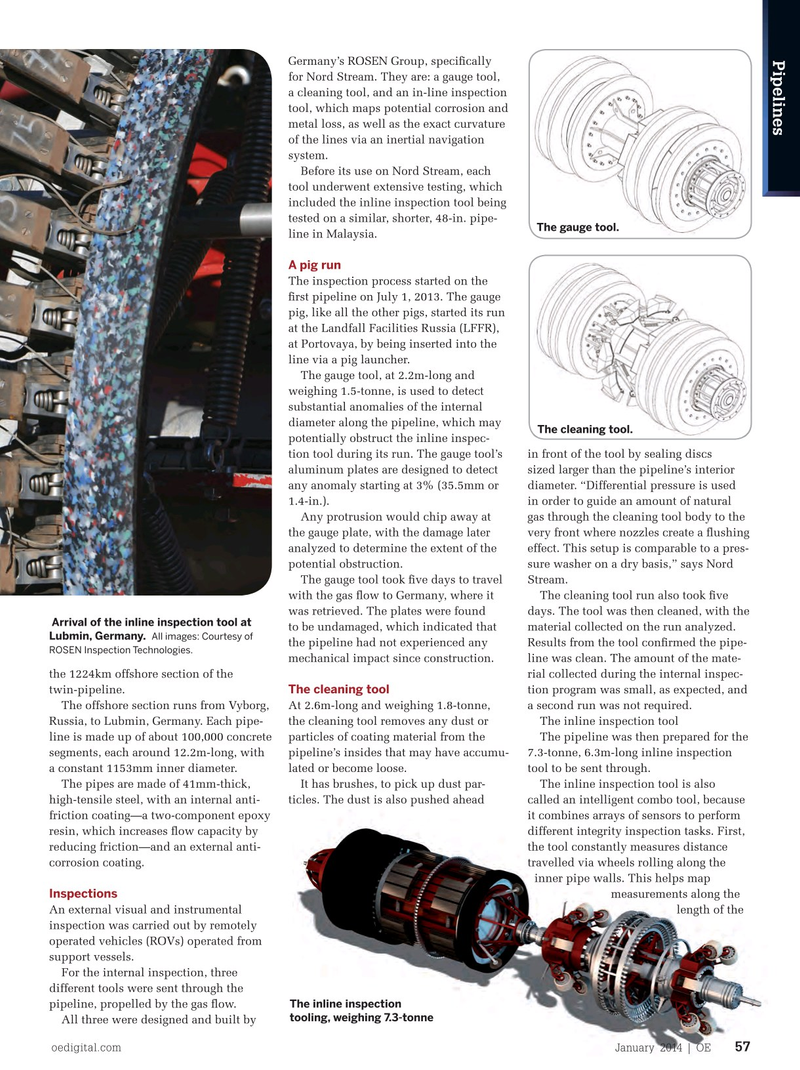

The cleaning tool quality of the Nord Stream pipeline twin-pipeline. tion program was small, as expected, and building process, and provide a data The offshore section runs from Vyborg, At 2.6m-long and weighing 1.8-tonne, a second run was not required. set, against which all future inspection Russia, to Lubmin, Germany. Each pipe- the cleaning tool removes any dust or The inline inspection tool results can be compared. line is made up of about 100,000 concrete particles of coating material from the The pipeline was then prepared for the

Andrey Voronov, offshore manager segments, each around 12.2m-long, with pipeline’s insides that may have accumu- 7.3-tonne, 6.3m-long inline inspection operations, Nord Stream, said: “Never a constant 1153mm inner diameter. lated or become loose. tool to be sent through. before has a pipeline with the similar The pipes are made of 41mm-thick, It has brushes, to pick up dust par- The inline inspection tool is also dimension been “pigged:” two 1224km- high-tensile steel, with an internal anti- ticles. The dust is also pushed ahead called an intelligent combo tool, because long 48-in.-diameter pipelines with wall friction coating—a two-component epoxy it combines arrays of sensors to perform thicknesses up to 41mm and up to 110mm resin, which increases ? ow capacity by different integrity inspection tasks. First, of concrete coating around it. Both the reducing friction—and an external anti- the tool constantly measures distance length and the thickness are unique and corrosion coating. travelled via wheels rolling along the posed engineering challenges for which inner pipe walls. This helps map

Inspections our inspection team and our partners at measurements along the

Rosen Group had to ? nd solutions.” An external visual and instrumental length of the

Inspection, as part of integrity manage- inspection was carried out by remotely ment measures for the system, was part operated vehicles (ROVs) operated from of the pipelines’ design from the start, support vessels. says Nord Stream. For the internal inspection, three

Integrity management measures different tools were sent through the

The inline inspection on Nord Stream cover its automation pipeline, propelled by the gas ? ow. tooling, weighing 7.3-tonne systems, landfall installations, and All three were designed and built by oedigital.com January 2014 | OE 57 056_OE0114_pipelines2 Nord Stream_BLJ.indd 57 12/19/13 6:32 PM

54

54

56

56