Page 35: of Offshore Engineer Magazine (Feb/Mar 2014)

Read this page in Pdf, Flash or Html5 edition of Feb/Mar 2014 Offshore Engineer Magazine

Production rates to more than 60%, says Moss water together and burning it across a by solid state diffusion bonding to form

Daemi, executive VP Middle East and very short distance,” says Alford. “As a structure containing internal passages,

Africa at DNV GL. we mix it together we are combusting with precise fow control manifolding

Oil frms have previously offered their it at more than 2000°C. Water is used and metering features, and flters. expertise for CO EOR in the region, to partly cool the gas before it hits the TriGen’s turbines are based on exist- 2 including BP, but with limited uptake, turbine blades and stop them melting, as ing technology machines, such as the due to not being deemed commercially their materials are not ready for this level Westinghouse W-251 (Siemen’s SGT- attractive enough, in a region “foating heat yet. As we can get turbines able to 900) are able to work with CO or steam 2 on oil”, and technically challenging. operate with the higher temperatures as a drive gas, because they can produce

It has been tried, however. In 2009, we would be able to further increase the drive gas at any combination of pressure

ADNOC’s onshore operating company, effciency.” and temperature.

started injecting CO at the onshore A key element of the Oxycombustor TriGen can also take in contaminated 2

North-East Bab feld, Rumaitha. In 2009, is “platelet” technology, which is used fuel gas streams, especially with CO . “It 2

Saudi Arabia’s Aramco announced plans for the fabrication of the combustor, to can be used for non-associated gas that to trial CO injection on mature felds control the reaction during the Oxy- you do not otherwise know what to do 2 including Ghawar. Combustion process, to ensure the oxy- with,” says Alford. After combustion, a

With concessions becoming available, gen and fuel mix to form a homogenous simple process is then used to separate operators are again offering their EOR fame front, avoiding hot spots or produc- the water and CO from the gas/steam 2 expertise, including Maersk. ing un-combusted product. turbine.

Bob Alford, senior business develop- The technology, which involves, The CO is used for oil recovery, with 2 ment manager, Maersk Oil Middle East, thru and partial-depth patterns chemi- any associated gas produced separated says Maersk has developed skills in tight, cally machined in thin sheets of metal, and recycled back into the process. Clean chalk, low permeability carbonate reser- producing “platelets,” was developed by Energy Systems, says the steam could voirs, common offshore Denmark, and in Maersk’s partner Clean Energy Systems. also be used for assisted gravity drainage the Middle East. The platelets are “stacked”, and joined or cyclic/constant steam foods.

Maersk has been operating the Al

Shaheen feld offshore Qatar since 1992.

It had been deemed uneconomic to produce, but it is now the biggest feld in

Qatar, producing 300,000 bbl/d.

has plans to increased daily production “The rock properties are very similar capacity to 3.5MM bbl/d, from 2.8MM here in Abu Dhabi, so we are excited bbl/d. about the opening of the market,” says

ADNOC is also looking to reduce CO Alford. 2 emissions. The frm recently signed a Maersk now has new technology up its joint venture (51:49) agreement with sleeve, which it wsays will help increase

Masdar to set up the Middle East’s frst EOR on this type of feld, and residual oil company focused on exploring and zones, without using imported natural developing commercial-scale projects for gas, as well as producing power, for the carbon capture, use and storage. local grid, and water, without the need

The JV plans to extract CO at Emirates for desalination—another issue facing the 2

Steel, the UAE’s largest steelmaking facil-

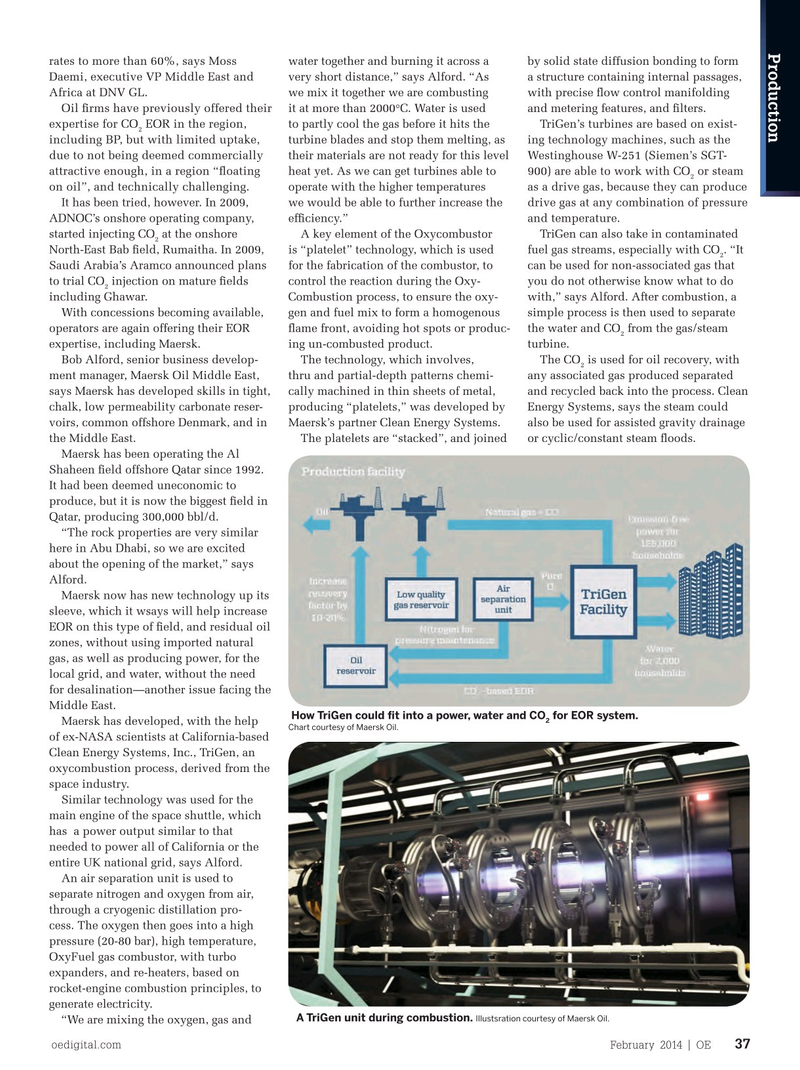

Middle East. How TriGen could ft into a power, water and CO for EOR system. 2 ity, compress it, and then transport it to

Maersk has developed, with the help

Chart courtesy of Maersk Oil.

ADNOC-operated oilfelds for EOR, and of ex-NASA scientists at California-based storage. The project will sequester up to

Clean Energy Systems, Inc., TriGen, an 800,000-ton of CO annually, says ADNOC.

oxycombustion process, derived from the 2

The agreement has already seen an space industry.

AED450 million engineering, procure- Similar technology was used for the ment and construction contract awarded main engine of the space shuttle, which to Dodsal Group to build a carbon diox- has a power output similar to that ide (CO ) compression facility in Abu needed to power all of California or the 2

Dhabi, and a 50km pipeline, with project entire UK national grid, says Alford. completion due in 2016. An air separation unit is used to

In addition, ADNOC is currently separate nitrogen and oxygen from air, selecting new partners for its legacy through a cryogenic distillation pro- onshore concession, due to expire this cess. The oxygen then goes into a high month [January], and an offshore conces- pressure (20-80 bar), high temperature, sion, scheduled to expire in 2018. OxyFuel gas combustor, with turbo

It is understood new concessions expanders, and re-heaters, based on being offered offshore Abu Dhabi by rocket-engine combustion principles, to

ADNOC will contain requirement for generate electricity.

A TriGen unit during combustion. Illustsration courtesy of Maersk Oil.

EOR initiatives in order to take recovery “We are mixing the oxygen, gas and oedigital.com February 2014 | OE 37 036_OE0214_ProdOps2_Maersk.indd 37 1/21/14 4:11 PM

34

34

36

36