Page 62: of Offshore Engineer Magazine (Apr/May 2014)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2014 Offshore Engineer Magazine

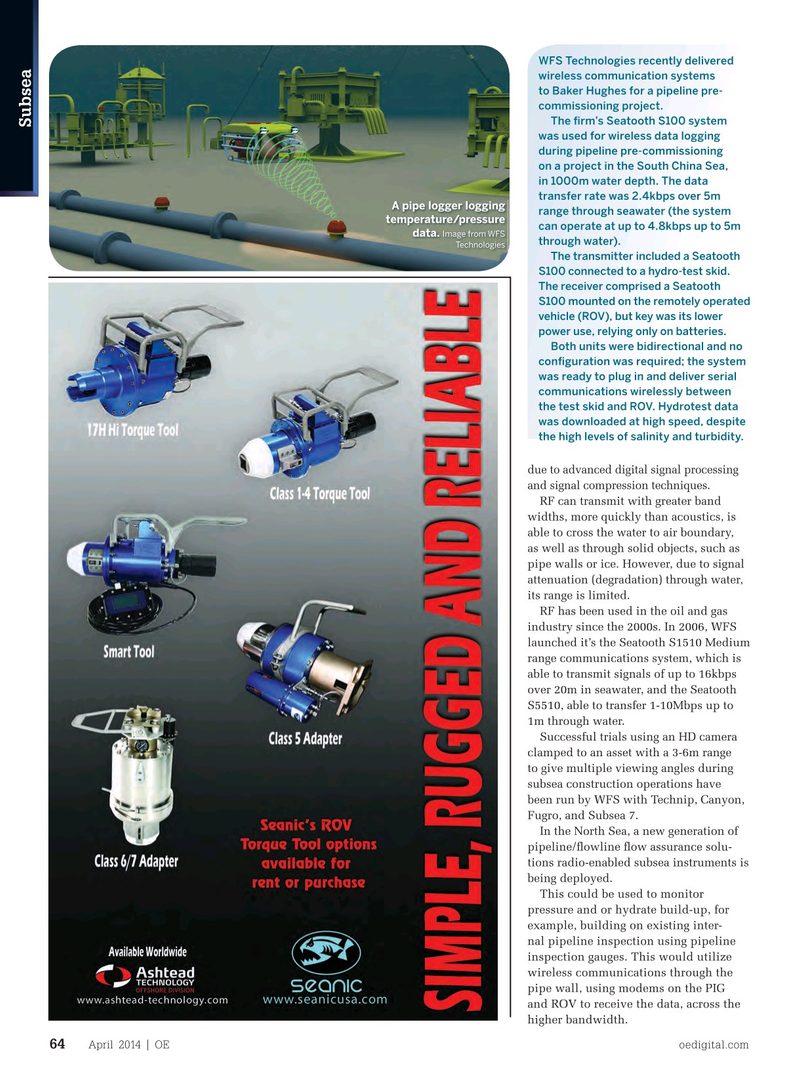

WFS Technologies recently delivered wireless communication systems to Baker Hughes for a pipeline pre- commissioning project.

The ? rm’s Seatooth S100 system

Subsea was used for wireless data logging during pipeline pre-commissioning on a project in the South China Sea, in 1000m water depth. The data transfer rate was 2.4kbps over 5m

A pipe logger logging range through seawater (the system temperature/pressure can operate at up to 4.8kbps up to 5m data. Image from WFS through water).

Technologies

The transmitter included a Seatooth

S100 connected to a hydro-test skid.

The receiver comprised a Seatooth

S100 mounted on the remotely operated vehicle (ROV), but key was its lower power use, relying only on batteries.

Both units were bidirectional and no con? guration was required; the system was ready to plug in and deliver serial communications wirelessly between the test skid and ROV. Hydrotest data was downloaded at high speed, despite the high levels of salinity and turbidity. due to advanced digital signal processing and signal compression techniques.

RF can transmit with greater band widths, more quickly than acoustics, is able to cross the water to air boundary, as well as through solid objects, such as pipe walls or ice. However, due to signal attenuation (degradation) through water, its range is limited.

RF has been used in the oil and gas industry since the 2000s. In 2006, WFS launched it’s the Seatooth S1510 Medium range communications system, which is able to transmit signals of up to 16kbps over 20m in seawater, and the Seatooth

S5510, able to transfer 1-10Mbps up to 1m through water.

Successful trials using an HD camera clamped to an asset with a 3-6m range to give multiple viewing angles during subsea construction operations have been run by WFS with Technip, Canyon,

Fugro, and Subsea 7.

In the North Sea, a new generation of pipeline/? owline ? ow assurance solu- tions radio-enabled subsea instruments is being deployed.

This could be used to monitor pressure and or hydrate build-up, for example, building on existing inter- nal pipeline inspection using pipeline inspection gauges. This would utilize wireless communications through the pipe wall, using modems on the PIG and ROV to receive the data, across the higher bandwidth.

April 2014 | OE oedigital.com 64 000_OE0414_Subsea1_wireless.indd 64 3/22/14 9:21 PM

61

61

63

63