Page 132: of Offshore Engineer Magazine (May/Jun 2014)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2014 Offshore Engineer Magazine

the subsequent double vessel, Cidade de Maricá and Cidade de Saquarema contract. “Petrobras gave us the awards because we have more capacity for local content,” said Levy, who sits on the

Vessels

Board of the Joint Venture in addition to his role as Brazil Country Director for

SBM Offshore.

The Brazilian scope for the conver- sion of the vessels is managed in close cooperation with the Rio offce of SBM

Offshore and a dedicated site team is in place at Brasa yard made up of combined resources from SBM’s Schiedam and Rio offces. Project completion for Cidade de

Ilhabela is scheduled for 2Q 2014.

“The arrival of FPSO Cidade de

Ilhabela to Brazil represents a newswor- thy double milestone for SBM Offshore.

Firstly the success of SBM’s global project management of her conversion at the CXG yard in China. Secondly as joint venture partners with Synergy in Brasa shipyard, we are very proud to welcome her to the quayside for the fnal integration of ten of her 18 modules, which were built here at

Brasa in Niteroi, Rio,” Levy said.

When asked about the safety systems aboard the new FPSO, Phillipe Levy was very direct, “Well, any FPSO is potentially explosive, so we take safety systems very

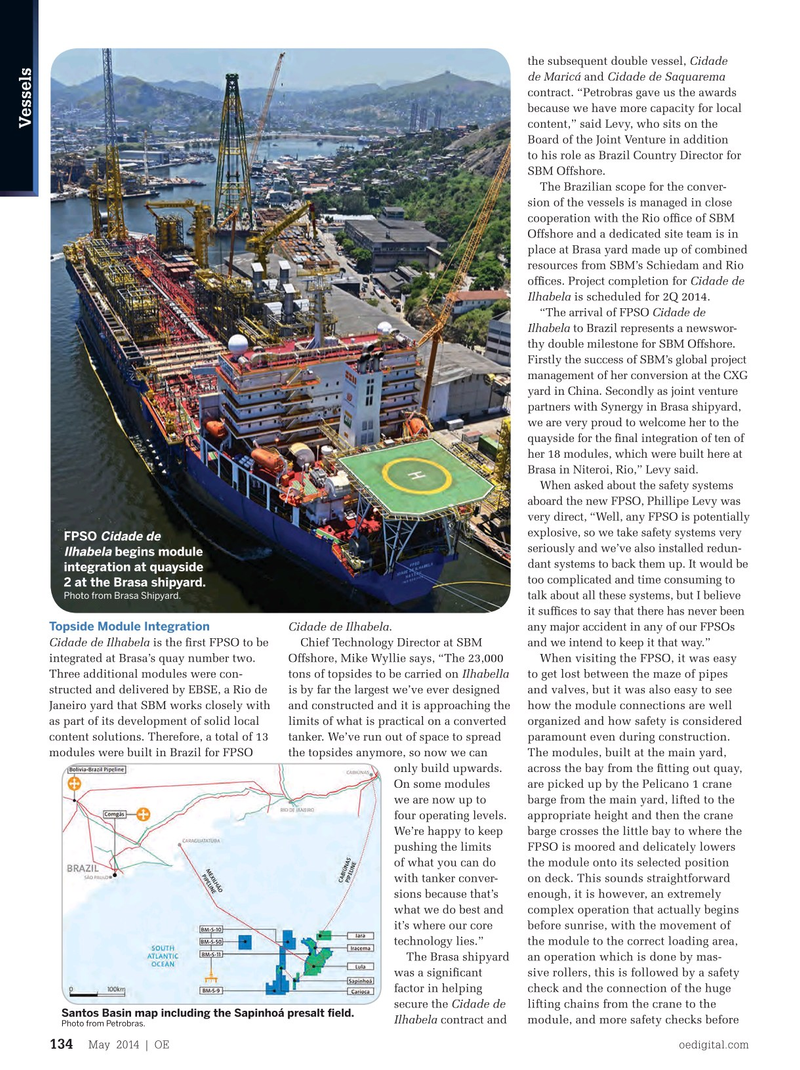

FPSO Cidade de seriously and we’ve also installed redun-

Ilhabela begins module dant systems to back them up. It would be integration at quayside too complicated and time consuming to 2 at the Brasa shipyard.

Photo from Brasa Shipyard.

talk about all these systems, but I believe it suffces to say that there has never been

Topside Module Integration

Cidade de Ilhabela. any major accident in any of our FPSOs

Cidade de Ilhabela is the frst FPSO to be Chief Technology Director at SBM and we intend to keep it that way.” integrated at Brasa’s quay number two. Offshore, Mike Wyllie says, “The 23,000 When visiting the FPSO, it was easy

Three additional modules were con- tons of topsides to be carried on Ilhabella to get lost between the maze of pipes structed and delivered by EBSE, a Rio de is by far the largest we’ve ever designed and valves, but it was also easy to see

Janeiro yard that SBM works closely with and constructed and it is approaching the how the module connections are well as part of its development of solid local limits of what is practical on a converted organized and how safety is considered content solutions. Therefore, a total of 13 tanker. We’ve run out of space to spread paramount even during construction. modules were built in Brazil for FPSO the topsides anymore, so now we can The modules, built at the main yard, only build upwards. across the bay from the ftting out quay,

On some modules are picked up by the Pelicano 1 crane we are now up to barge from the main yard, lifted to the four operating levels. appropriate height and then the crane

We’re happy to keep barge crosses the little bay to where the pushing the limits FPSO is moored and delicately lowers of what you can do the module onto its selected position with tanker conver- on deck. This sounds straightforward sions because that’s enough, it is however, an extremely what we do best and complex operation that actually begins it’s where our core before sunrise, with the movement of technology lies.” the module to the correct loading area,

The Brasa shipyard an operation which is done by mas- was a signifcant sive rollers, this is followed by a safety factor in helping check and the connection of the huge secure the Cidade de lifting chains from the crane to the

Santos Basin map including the Sapinhoa presalt feld.

Ilhabela contract and module, and more safety checks before

Photo from Petrobras.

May 2014 | OE oedigital.com 134 130_OE0514_Vessels3_SBM.indd 134 4/18/14 10:03 PM

131

131

133

133