Page 142: of Offshore Engineer Magazine (May/Jun 2014)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2014 Offshore Engineer Magazine

An independent testing and verifca- tion program is about to start, Selwa says, as well as site survey work, for an environmental impact assessment, required for a feld development plan to

Vessels be approved.

The UPB system

The frm, led by founder and chairman

Richard Selwa, says its reusable design is based on mass-manufacturing principles, using standardized components, based on learnings from tank farms in Canada, and the principles of onshore “nodding donkeys”.

UPB’s design comprises three main parts, a 1800-tonne dry-weight semi-sub- merged buoy, a 500-tonne subsea, steel, sealed tank system, and a combined, ser- vice riser bundle. The riser bundle will connect to up to three subsea production wells and two water injection wells, via infeld fowlines, and be expected to produce 600-15,000 bo/d over a 20-year life span.

Selwa says the maximum 28m-diameter buoy and 200,000 bbl-capacity gravity- based storage tanks, both fabricated from steel, are standard designs. Depending on depth, the buoy will either be moored with a spread mooring system (60-90m) or tension leg confguration (90m+), with a standard offoading system.

The production system will be a standardized, temperature-stabilized,

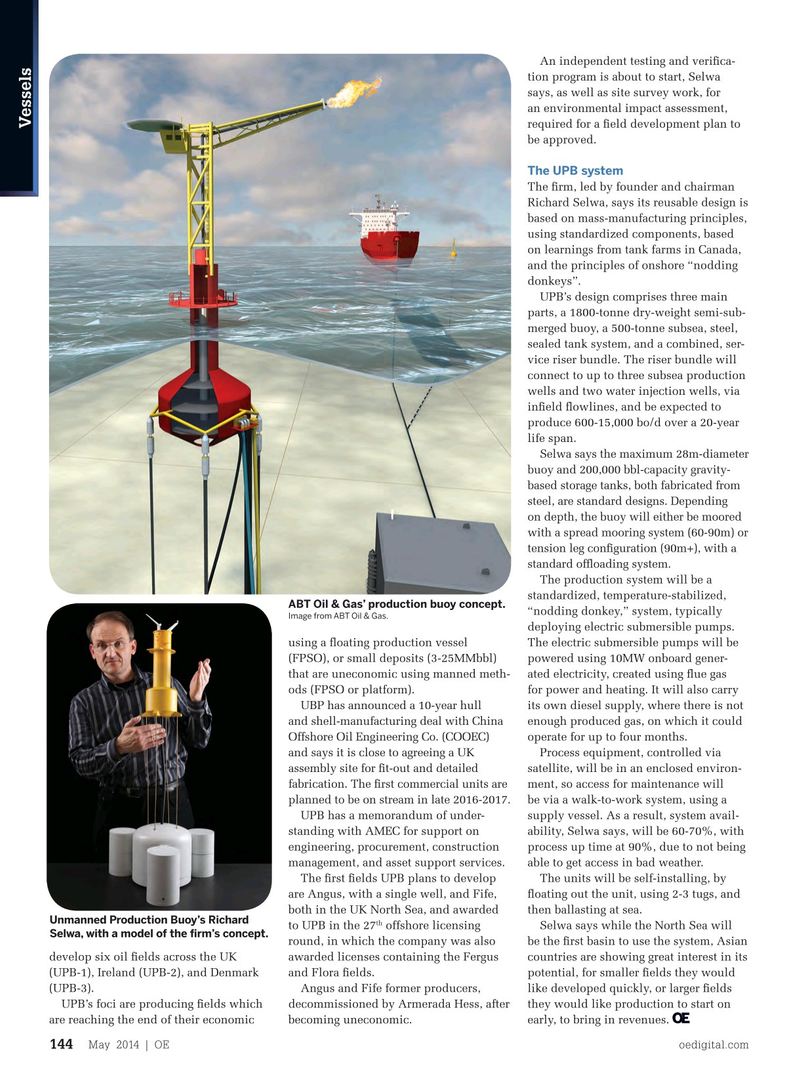

ABT Oil & Gas’ production buoy concept. “nodding donkey,” system, typically

Image from ABT Oil & Gas. deploying electric submersible pumps. using a foating production vessel The electric submersible pumps will be (FPSO), or small deposits (3-25MMbbl) powered using 10MW onboard gener- that are uneconomic using manned meth- ated electricity, created using fue gas ods (FPSO or platform). for power and heating. It will also carry

UBP has announced a 10-year hull its own diesel supply, where there is not and shell-manufacturing deal with China enough produced gas, on which it could

Offshore Oil Engineering Co. (COOEC) operate for up to four months. and says it is close to agreeing a UK Process equipment, controlled via assembly site for ft-out and detailed satellite, will be in an enclosed environ- fabrication. The frst commercial units are ment, so access for maintenance will planned to be on stream in late 2016-2017. be via a walk-to-work system, using a

UPB has a memorandum of under- supply vessel. As a result, system avail- standing with AMEC for support on ability, Selwa says, will be 60-70%, with engineering, procurement, construction process up time at 90%, due to not being management, and asset support services. able to get access in bad weather.

The frst felds UPB plans to develop The units will be self-installing, by are Angus, with a single well, and Fife, foating out the unit, using 2-3 tugs, and both in the UK North Sea, and awarded then ballasting at sea.

Unmanned Production Buoy’s Richard th to UPB in the 27 offshore licensing Selwa says while the North Sea will

Selwa, with a model of the frm’s concept.

round, in which the company was also be the frst basin to use the system, Asian develop six oil felds across the UK awarded licenses containing the Fergus countries are showing great interest in its (UPB-1), Ireland (UPB-2), and Denmark and Flora felds. potential, for smaller felds they would (UPB-3). Angus and Fife former producers, like developed quickly, or larger felds

UPB’s foci are producing felds which decommissioned by Armerada Hess, after they would like production to start on are reaching the end of their economic becoming uneconomic. early, to bring in revenues.

May 2014 | OE oedigital.com 144 138_OE0514_Vessels4_unmanned.indd 144 4/19/14 10:34 AM

141

141

143

143