Page 163: of Offshore Engineer Magazine (May/Jun 2014)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2014 Offshore Engineer Magazine

on exceptions or other situations that need expert attention. Standardization and the high level of accu- racy from the upgrades has improved Chevron’s Gulf operation.

As a result, UWT is building an enterprise version of the Gulf of Mexico’s logistics solution for deployment

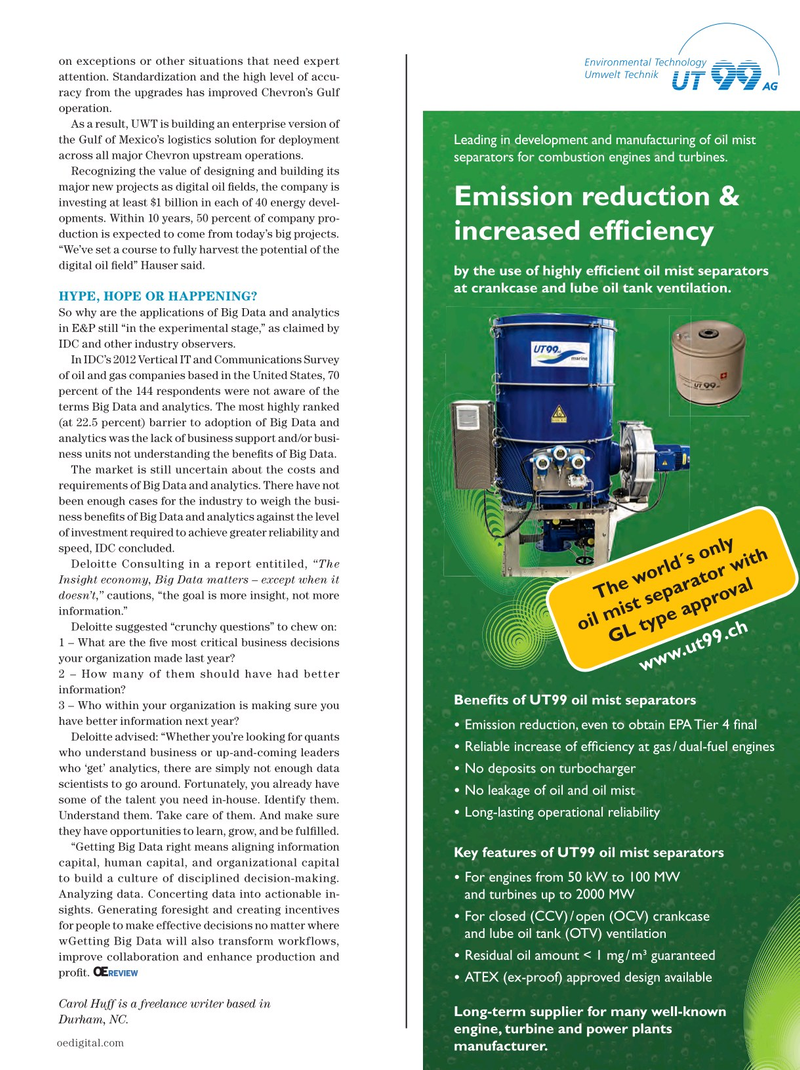

Leading in development and manufacturing of oil mist across all major Chevron upstream operations. separators for combustion engines and turbines.

Recognizing the value of designing and building its major new projects as digital oil ? elds, the company is

Emission reduction & investing at least $1 billion in each of 40 energy devel- opments. Within 10 years, 50 percent of company pro- duction is expected to come from today’s big projects. increased effciency “We’ve set a course to fully harvest the potential of the digital oil ? eld” Hauser said.

by the use of highly effcient oil mist separators at crankcase and lube oil tank ventilation.

HYPE, HOPE OR HAPPENING?

So why are the applications of Big Data and analytics in E&P still “in the experimental stage,” as claimed by

IDC and other industry observers.

In IDC’s 2012 Vertical IT and Communications Survey of oil and gas companies based in the United States, 70 percent of the 144 respondents were not aware of the terms Big Data and analytics. The most highly ranked (at 22.5 percent) barrier to adoption of Big Data and analytics was the lack of business support and/or busi- ness units not understanding the bene? ts of Big Data.

The market is still uncertain about the costs and requirements of Big Data and analytics. There have not been enough cases for the industry to weigh the busi- ness bene? ts of Big Data and analytics against the level of investment required to achieve greater reliability and speed, IDC concluded.

Deloitte Consulting in a report entitiled, “The

Insight economy, Big Data matters – except when it doesn’t,” cautions, “the goal is more insight, not more

The world´s only information.”

Deloitte suggested “crunchy questions” to chew on: oil mist separator with

GL type approval 1 – What are the ? ve most critical business decisions your organization made last year?

www.ut99.ch 2 – How many of them should have had better information?

Benefts of UT99 oil mist separators 3 – Who within your organization is making sure you have better information next year?

•

Emission reduction, even to obtain EPA Tier 4 fnal

Deloitte advised: “Whether you’re looking for quants •

Reliable increase of effciency at gas / dual-fuel engines who understand business or up-and-coming leaders who ‘get’ analytics, there are simply not enough data •

No deposits on turbocharger scientists to go around. Fortunately, you already have •

No leakage of oil and oil mist some of the talent you need in-house. Identify them. •

Long-lasting operational reliability

Understand them. Take care of them. And make sure they have opportunities to learn, grow, and be ful? lled.

“Getting Big Data right means aligning information

Key features of UT99 oil mist separators capital, human capital, and organizational capital •

For engines from 50 kW to 100 MW to build a culture of disciplined decision-making.

Analyzing data. Concerting data into actionable in- and turbines up to 2000 MW sights. Generating foresight and creating incentives •

For closed (CCV) / open (OCV) crankcase for people to make effective decisions no matter where and lube oil tank (OTV) ventilation wGetting Big Data will also transform workflows, •

Residual oil amount < 1 mg / m³ guaranteed improve collaboration and enhance production and

OE REVIEW pro? t. •

ATEX (ex-proof) approved design available

Carol Huff is a freelance writer based in

Long-term supplier for many well-known

Durham, NC.

engine, turbine and power plants oedigital.com 165

May 2014 | OE REVIEW manufacturer.

158_0514OER_Big_Data.indd 165 4/19/14 11:17 AM

162

162

164

164