Page 96: of Offshore Engineer Magazine (May/Jun 2014)

Read this page in Pdf, Flash or Html5 edition of May/Jun 2014 Offshore Engineer Magazine

boosting increases the fow rate of the oil or gas to the surface by reducing the back pressure on the well, and therefore increases the recovery factor of the reser-

Subsea voir. For oil, pumping can be used, while

Profcient natural gases are boosted by compres- sion. Another technique, which can be used in combination with pumping, is to separate the water and oil/gas, injecting processing the water back into the reservoir to limit pressure drops in the well. This saves hydrates on the pipe walls or the mixed energy (the potential energy of getting

TE Connectivity’s water cut freezing. Either can restrict the water to the topside facility and

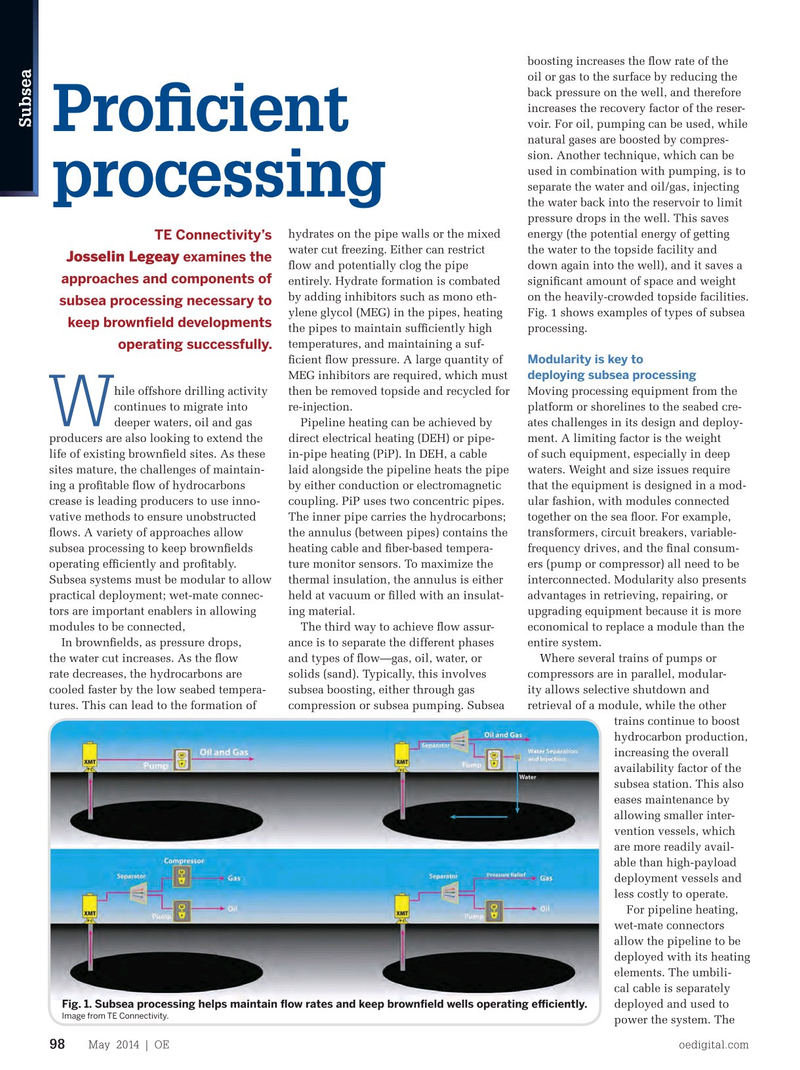

Josselin Legeay examines the fow and potentially clog the pipe down again into the well), and it saves a approaches and components of entirely. Hydrate formation is combated signifcant amount of space and weight by adding inhibitors such as mono eth- on the heavily-crowded topside facilities. subsea processing necessary to ylene glycol (MEG) in the pipes, heating Fig. 1 shows examples of types of subsea keep brownfeld developments the pipes to maintain suffciently high processing.

temperatures, and maintaining a suf- operating successfully.

Modularity is key to fcient fow pressure. A large quantity of deploying subsea processing

MEG inhibitors are required, which must hile offshore drilling activity then be removed topside and recycled for Moving processing equipment from the continues to migrate into re-injection. platform or shorelines to the seabed cre-

W deeper waters, oil and gas Pipeline heating can be achieved by ates challenges in its design and deploy- producers are also looking to extend the direct electrical heating (DEH) or pipe- ment. A limiting factor is the weight life of existing brownfeld sites. As these in-pipe heating (PiP). In DEH, a cable of such equipment, especially in deep sites mature, the challenges of maintain- laid alongside the pipeline heats the pipe waters. Weight and size issues require ing a proftable fow of hydrocarbons by either conduction or electromagnetic that the equipment is designed in a mod- crease is leading producers to use inno- coupling. PiP uses two concentric pipes. ular fashion, with modules connected vative methods to ensure unobstructed The inner pipe carries the hydrocarbons; together on the sea foor. For example, fows. A variety of approaches allow the annulus (between pipes) contains the transformers, circuit breakers, variable- subsea processing to keep brownfelds heating cable and fber-based tempera- frequency drives, and the fnal consum- operating effciently and proftably. ture monitor sensors. To maximize the ers (pump or compressor) all need to be

Subsea systems must be modular to allow thermal insulation, the annulus is either interconnected. Modularity also presents practical deployment; wet-mate connec- held at vacuum or flled with an insulat- advantages in retrieving, repairing, or tors are important enablers in allowing ing material. upgrading equipment because it is more modules to be connected, The third way to achieve fow assur- economical to replace a module than the

In brownfelds, as pressure drops, ance is to separate the different phases entire system.

the water cut increases. As the fow and types of fow—gas, oil, water, or Where several trains of pumps or rate decreases, the hydrocarbons are solids (sand). Typically, this involves compressors are in parallel, modular- cooled faster by the low seabed tempera- subsea boosting, either through gas ity allows selective shutdown and tures. This can lead to the formation of compression or subsea pumping. Subsea retrieval of a module, while the other trains continue to boost hydrocarbon production, increasing the overall availability factor of the subsea station. This also eases maintenance by allowing smaller inter- vention vessels, which are more readily avail- able than high-payload deployment vessels and less costly to operate.

For pipeline heating, wet-mate connectors allow the pipeline to be deployed with its heating elements. The umbili- cal cable is separately deployed and used to

Fig. 1. Subsea processing helps maintain fow rates and keep brownfeld wells operating efciently.

Image from TE Connectivity.

power the system. The

May 2014 | OE oedigital.com 98 100_0514Subsea4_TE Connectivity.indd 98 4/19/14 9:14 AM

95

95

97

97