Page 46: of Offshore Engineer Magazine (Jul/Aug 2014)

Read this page in Pdf, Flash or Html5 edition of Jul/Aug 2014 Offshore Engineer Magazine

Subsea

In? atable seals for critical offshore applications high-pressure seals is elongation of the

Bruno Rouchouze and Cindy Krishna, of Technetics Group, discuss lateral faces of a squarish pro? le cross- the mechanics of in? atable seals and their applications. section (Figure 2). section (Figure 2).

High-pressure in? atable seals are High-pressure in? atable seals are n? atable sealing technology is used n? atable sealing technology is used designed to ? t in metal retaining grooves, designed to ? t in metal retaining grooves, in a number of critical applications in a number of critical applications allowing axial, external radial and allowing axial, external radial and

Iincluding offshore production, including offshore production, internal radial expansion, These seals internal radial expansion, These seals storage and of? oading (FPSO); typically can withstand pressures of up typically can withstand pressures of up anchoring drill rigs to the seabed; to 8 bar, and are suitable for sealing clear-to 8 bar, and are suitable for sealing clear- gas loading systems; pipeline ances from 2-10mm. ances from 2-10mm. welding; and watertight doors and welding; and watertight doors and Low-pressure seals work by geometric Low-pressure seals work by geometric panels. deformation of an omega-shaped pro? le deformation of an omega-shaped pro? le

In? atable seals are the safest and In? atable seals are the safest and (Figure 3). (Figure 3). easiest method of sealing compo- easiest method of sealing compo- Capable of handling external pressures Capable of handling external pressures nents that move in relation to one nents that move in relation to one up to 2.5 bar, they can be expanded up to 2.5 bar, they can be expanded another, and are frequently connected another, and are frequently connected 5-30mm to seal larger clearances. 5-30mm to seal larger clearances. and disconnected. Capable of adapting and disconnected. Capable of adapting Both types of seals can be in? ated Both types of seals can be in? ated to varying environmental and service to varying environmental and service with compressed air or nitrogen, with compressed air or nitrogen, conditions, these type seals can be conditions, these type seals can be which will slowly leak through the which will slowly leak through the expanded and contracted pneumatically expanded and contracted pneumatically material, necessitating occasional re-material, necessitating occasional re- or hydraulically to accommodate these or hydraulically to accommodate these in? ation. They also can be in? ated in? ation. They also can be in? ated changes. with liquids such as water or oil, with liquids such as water or oil,

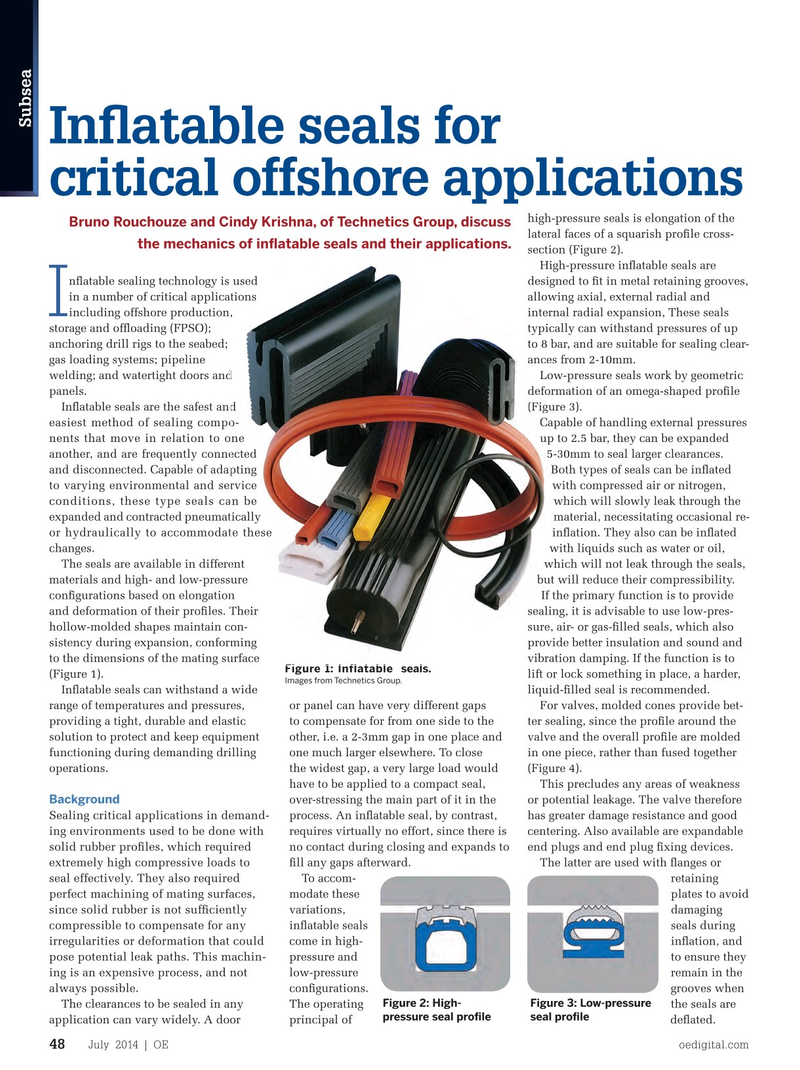

The seals are available in different The seals are available in different which will not leak through the seals, which will not leak through the seals, materials and high- and low-pressure materials and high- and low-pressure but will reduce their compressibility. but will reduce their compressibility. con? gurations based on elongation con? gurations based on elongation If the primary function is to provide If the primary function is to provide and deformation of their pro? les. Their and deformation of their pro? les. Their sealing, it is advisable to use low-pres-sealing, it is advisable to use low-pres- hollow-molded shapes maintain con- hollow-molded shapes maintain con- sure, air- or gas-? lled seals, which also sure, air- or gas-? lled seals, which also sistency during expansion, conforming sistency during expansion, conforming provide better insulation and sound and provide better insulation and sound and to the dimensions of the mating surface to the dimensions of the mating surface vibration damping. If the function is to vibration damping. If the function is to

Figure 1: Inflatable seals.Figure 1: Inflatable seals. (Figure 1). lift or lock something in place, a harder,

Images from Technetics Group.

In? atable seals can withstand a wide liquid-? lled seal is recommended. range of temperatures and pressures, or panel can have very different gaps For valves, molded cones provide bet- providing a tight, durable and elastic to compensate for from one side to the ter sealing, since the pro? le around the solution to protect and keep equipment other, i.e. a 2-3mm gap in one place and valve and the overall pro? le are molded functioning during demanding drilling one much larger elsewhere. To close in one piece, rather than fused together operations. the widest gap, a very large load would (Figure 4).

have to be applied to a compact seal, This precludes any areas of weakness

Background over-stressing the main part of it in the or potential leakage. The valve therefore

Sealing critical applications in demand- process. An in? atable seal, by contrast, has greater damage resistance and good ing environments used to be done with requires virtually no effort, since there is centering. Also available are expandable solid rubber pro? les, which required no contact during closing and expands to end plugs and end plug ? xing devices. extremely high compressive loads to ? ll any gaps afterward. The latter are used with ? anges or seal effectively. They also required

To accom- retaining perfect machining of mating surfaces, modate these plates to avoid since solid rubber is not suf? ciently variations, damaging compressible to compensate for any in? atable seals seals during irregularities or deformation that could come in high- in? ation, and pose potential leak paths. This machin- pressure and to ensure they ing is an expensive process, and not low-pressure remain in the always possible. con? gurations. grooves when

Figure 2: High- Figure 3: Low-pressure

The clearances to be sealed in any The operating the seals are pressure seal pro? le seal pro? le application can vary widely. A door principal of de? ated.

July 2014 | OE oedigital.com 48 050_OE0714_Subsea_Inflatable seals.indd 48 6/20/14 6:43 PM

45

45

47

47