Page 98: of Offshore Engineer Magazine (Aug/Sep 2014)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2014 Offshore Engineer Magazine

costs. One potential driver to capex cost reduction is to look more closely at the tensioner pad itself.

The tensioner pad is at the heart of the tensioner. It is a small piece of rubber/steel,

Testing

Flowlines which is pivotal to assuring safe and ef? - cient operations. At this critical and highly complex frictional interface between the installation machine and the product, it under tension would be good to know what is actually going on. In deeper ? elds, knowledge in

Using the tensioner test rig he technical demands on pipeline this area moves from being good to know installers continue to grow, due to to being essential to fully understand. This simulator can show how to

T the need to service the deeper ? eld is a specialized area MacKinnon Marine improve tensioner pad design, depths being exploited. Equipment provid- has research and development experience ers are responding, with the result that in, as well as a test facility. says MacKinnon Marine’s Alex

The best way is to trial a system is to everything is getting bigger and heavier.

MacKinnon.

Unfortunately, in many cases this comes replicate the offshore installation condi- at the price of poorer operability, and ten- tions in a simulation test facility, using sioners are no exception. Tensioners are the same full-size tensioner pads you are

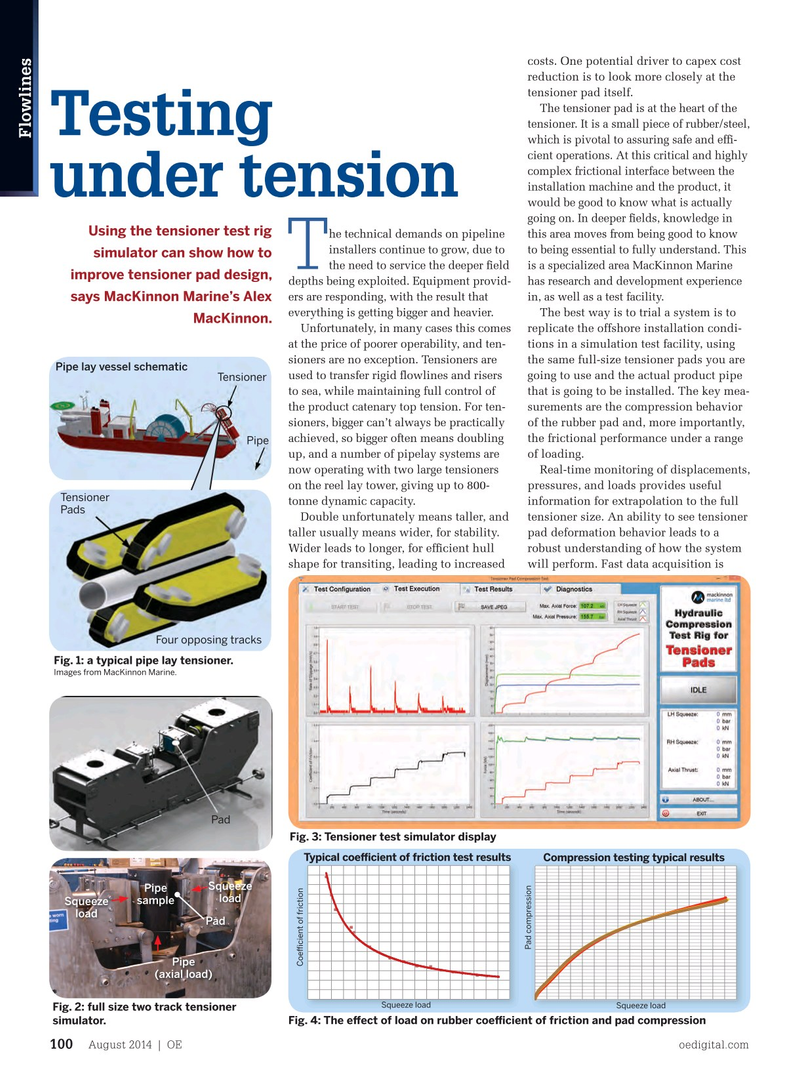

Pipe lay vessel schematic used to transfer rigid ? owlines and risers going to use and the actual product pipe

Tensioner to sea, while maintaining full control of that is going to be installed. The key mea- the product catenary top tension. For ten- surements are the compression behavior sioners, bigger can’t always be practically of the rubber pad and, more importantly, achieved, so bigger often means doubling the frictional performance under a range

Pipe up, and a number of pipelay systems are of loading.

now operating with two large tensioners Real-time monitoring of displacements, on the reel lay tower, giving up to 800- pressures, and loads provides useful

Tensioner tonne dynamic capacity. information for extrapolation to the full

Pads

Double unfortunately means taller, and tensioner size. An ability to see tensioner taller usually means wider, for stability. pad deformation behavior leads to a

Wider leads to longer, for ef? cient hull robust understanding of how the system shape for transiting, leading to increased will perform. Fast data acquisition is

Four opposing tracks

Fig. 1: a typical pipe lay tensioner.

Images from MacKinnon Marine.

Pad

Fig. 3: Tensioner test simulator display

Typical coe

97

97

99

99