Page 138: of Offshore Engineer Magazine (Aug/Sep 2014)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2014 Offshore Engineer Magazine

invested in ? ber optic lines out to their platforms, ev- erybody else in the Gulf is relying on one of two satel-

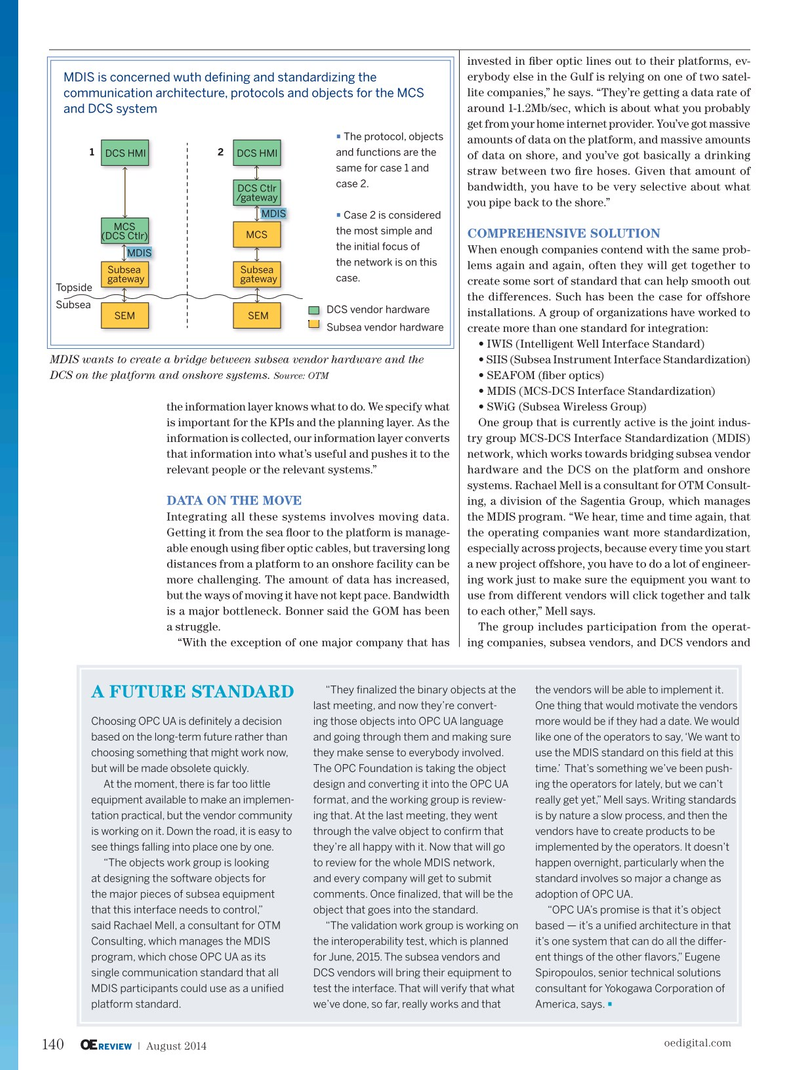

MDIS is concerned wuth de? ning and standardizing the lite companies,” he says. “They’re getting a data rate of communication architecture, protocols and objects for the MCS around 1-1.2Mb/sec, which is about what you probably and DCS system get from your home internet provider. You’ve got massive • The protocol, objects amounts of data on the platform, and massive amounts 1 2 and functions are the

DCS HMI DCS HMI of data on shore, and you’ve got basically a drinking same for case 1 and straw between two ? re hoses. Given that amount of case 2.

bandwidth, you have to be very selective about what

DCS Ctlr /gateway you pipe back to the shore.”

MDIS • Case 2 is considered

MCS the most simple and

COMPREHENSIVE SOLUTION

MCS (DCS Ctlr) the initial focus of

When enough companies contend with the same prob-

MDIS the network is on this lems again and again, often they will get together to

Subsea Subsea case.

gateway gateway create some sort of standard that can help smooth out

Topside the differences. Such has been the case for offshore

Subsea

DCS vendor hardware installations. A group of organizations have worked to

SEM SEM

Subsea vendor hardware create more than one standard for integration: • IWIS (Intelligent Well Interface Standard)

MDIS wants to create a bridge between subsea vendor hardware and the • SIIS (Subsea Instrument Interface Standardization)

Source: OTM

DCS on the platform and onshore systems. • SEAFOM (? ber optics) • MDIS (MCS-DCS Interface Standardization) the information layer knows what to do. We specify what • SWiG (Subsea Wireless Group) is important for the KPIs and the planning layer. As the One group that is currently active is the joint indus- information is collected, our information layer converts try group MCS-DCS Interface Standardization (MDIS) that information into what’s useful and pushes it to the network, which works towards bridging subsea vendor relevant people or the relevant systems.” hardware and the DCS on the platform and onshore systems. Rachael Mell is a consultant for OTM Consult-

DATA ON THE MOVE ing, a division of the Sagentia Group, which manages

Integrating all these systems involves moving data. the MDIS program. “We hear, time and time again, that

Getting it from the sea ? oor to the platform is manage- the operating companies want more standardization, able enough using ? ber optic cables, but traversing long especially across projects, because every time you start distances from a platform to an onshore facility can be a new project offshore, you have to do a lot of engineer- more challenging. The amount of data has increased, ing work just to make sure the equipment you want to but the ways of moving it have not kept pace. Bandwidth use from different vendors will click together and talk is a major bottleneck. Bonner said the GOM has been to each other,” Mell says.

a struggle. The group includes participation from the operat- “With the exception of one major company that has ing companies, subsea vendors, and DCS vendors and “They ? nalized the binary objects at the the vendors will be able to implement it.

A FUTURE STANDARD last meeting, and now they’re convert- One thing that would motivate the vendors

Choosing OPC UA is de? nitely a decision ing those objects into OPC UA language more would be if they had a date. We would based on the long-term future rather than and going through them and making sure like one of the operators to say, ‘We want to choosing something that might work now, they make sense to everybody involved. use the MDIS standard on this ? eld at this but will be made obsolete quickly. The OPC Foundation is taking the object time.’ That’s something we’ve been push-

At the moment, there is far too little design and converting it into the OPC UA ing the operators for lately, but we can’t equipment available to make an implemen- format, and the working group is review- really get yet,” Mell says. Writing standards tation practical, but the vendor community ing that. At the last meeting, they went is by nature a slow process, and then the is working on it. Down the road, it is easy to through the valve object to con? rm that vendors have to create products to be see things falling into place one by one. they’re all happy with it. Now that will go implemented by the operators. It doesn’t “The objects work group is looking to review for the whole MDIS network, happen overnight, particularly when the at designing the software objects for and every company will get to submit standard involves so major a change as the major pieces of subsea equipment comments. Once ? nalized, that will be the adoption of OPC UA.

that this interface needs to control,” object that goes into the standard. “OPC UA’s promise is that it’s object said Rachael Mell, a consultant for OTM “The validation work group is working on based — it’s a uni? ed architecture in that

Consulting, which manages the MDIS the interoperability test, which is planned it’s one system that can do all the di

137

137

139

139