Page 32: of Offshore Engineer Magazine (Aug/Sep 2014)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2014 Offshore Engineer Magazine

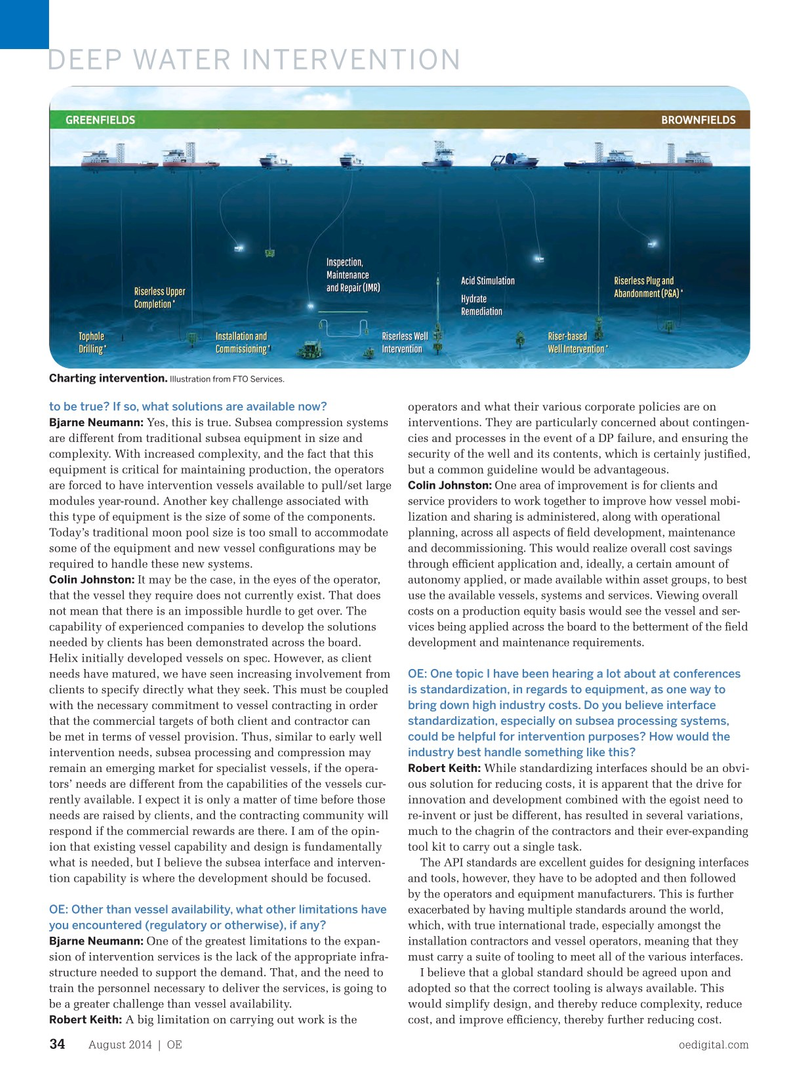

DEEP WATER INTERVENTION

Charting intervention.

Illustration from FTO Services.

to be true? If so, what solutions are available now? operators and what their various corporate policies are on

Bjarne Neumann: Yes, this is true. Subsea compression systems interventions. They are particularly concerned about contingen- are different from traditional subsea equipment in size and cies and processes in the event of a DP failure, and ensuring the complexity. With increased complexity, and the fact that this security of the well and its contents, which is certainly justifed, equipment is critical for maintaining production, the operators but a common guideline would be advantageous.

Colin Johnston: are forced to have intervention vessels available to pull/set large One area of improvement is for clients and modules year-round. Another key challenge associated with service providers to work together to improve how vessel mobi- this type of equipment is the size of some of the components. lization and sharing is administered, along with operational

Today’s traditional moon pool size is too small to accommodate planning, across all aspects of feld development, maintenance some of the equipment and new vessel confgurations may be and decommissioning. This would realize overall cost savings required to handle these new systems. through effcient application and, ideally, a certain amount of

Colin Johnston:

It may be the case, in the eyes of the operator, autonomy applied, or made available within asset groups, to best that the vessel they require does not currently exist. That does use the available vessels, systems and services. Viewing overall not mean that there is an impossible hurdle to get over. The costs on a production equity basis would see the vessel and ser- capability of experienced companies to develop the solutions vices being applied across the board to the betterment of the feld needed by clients has been demonstrated across the board. development and maintenance requirements.

Helix initially developed vessels on spec. However, as client needs have matured, we have seen increasing involvement from OE: One topic I have been hearing a lot about at conferences clients to specify directly what they seek. This must be coupled is standardization, in regards to equipment, as one way to with the necessary commitment to vessel contracting in order bring down high industry costs. Do you believe interface that the commercial targets of both client and contractor can standardization, especially on subsea processing systems, be met in terms of vessel provision. Thus, similar to early well could be helpful for intervention purposes? How would the intervention needs, subsea processing and compression may industry best handle something like this?

Robert Keith: remain an emerging market for specialist vessels, if the opera- While standardizing interfaces should be an obvi- tors’ needs are different from the capabilities of the vessels cur- ous solution for reducing costs, it is apparent that the drive for rently available. I expect it is only a matter of time before those innovation and development combined with the egoist need to needs are raised by clients, and the contracting community will re-invent or just be different, has resulted in several variations, respond if the commercial rewards are there. I am of the opin- much to the chagrin of the contractors and their ever-expanding ion that existing vessel capability and design is fundamentally tool kit to carry out a single task.

The API standards are excellent guides for designing interfaces what is needed, but I believe the subsea interface and interven- and tools, however, they have to be adopted and then followed tion capability is where the development should be focused.

by the operators and equipment manufacturers. This is further exacerbated by having multiple standards around the world,

OE: Other than vessel availability, what other limitations have which, with true international trade, especially amongst the you encountered (regulatory or otherwise), if any?

One of the greatest limitations to the expan-

Bjarne Neumann: installation contractors and vessel operators, meaning that they sion of intervention services is the lack of the appropriate infra- must carry a suite of tooling to meet all of the various interfaces. structure needed to support the demand. That, and the need to I believe that a global standard should be agreed upon and train the personnel necessary to deliver the services, is going to adopted so that the correct tooling is always available. This be a greater challenge than vessel availability. would simplify design, and thereby reduce complexity, reduce A big limitation on carrying out work is the cost, and improve effciency, thereby further reducing cost.

Robert Keith:

August 2014 | OE oedigital.com 34 032_OE0814_DWI1_DIF roundtable.indd 34 7/22/14 9:08 PM

31

31

33

33