Page 47: of Offshore Engineer Magazine (Aug/Sep 2014)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2014 Offshore Engineer Magazine

Geology & Geophysics

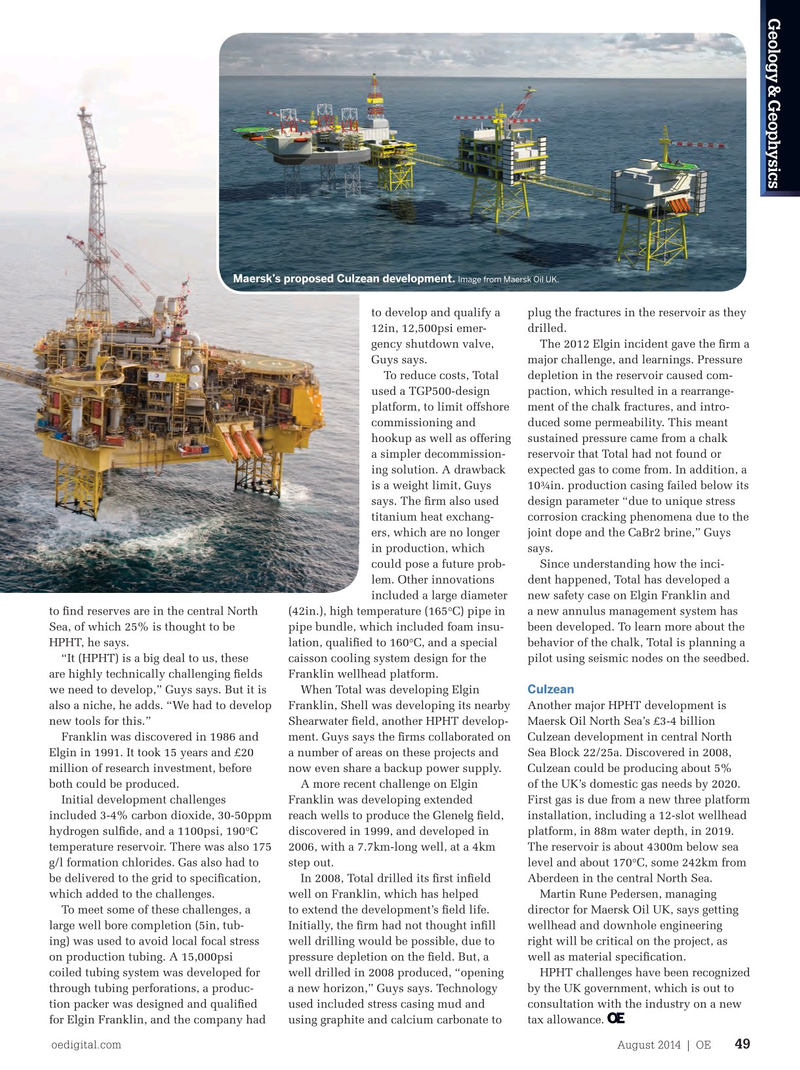

Maersk’s proposed Culzean development. Image from Maersk Oil UK. to develop and qualify a plug the fractures in the reservoir as they 12in, 12,500psi emer- drilled. gency shutdown valve, The 2012 Elgin incident gave the ? rm a

Guys says. major challenge, and learnings. Pressure

To reduce costs, Total depletion in the reservoir caused com- used a TGP500-design paction, which resulted in a rearrange- platform, to limit offshore ment of the chalk fractures, and intro- commissioning and duced some permeability. This meant hookup as well as offering sustained pressure came from a chalk a simpler decommission- reservoir that Total had not found or ing solution. A drawback expected gas to come from. In addition, a is a weight limit, Guys 10¾in. production casing failed below its says. The ? rm also used design parameter “due to unique stress titanium heat exchang- corrosion cracking phenomena due to the ers, which are no longer joint dope and the CaBr2 brine,” Guys in production, which says. could pose a future prob- Since understanding how the inci- lem. Other innovations dent happened, Total has developed a included a large diameter new safety case on Elgin Franklin and operators, primarily GDF Suez E&P, but to ? nd reserves are in the central North (42in.), high temperature (165°C) pipe in a new annulus management system has also Maersk, to make it and other projects Sea, of which 25% is thought to be pipe bundle, which included foam insu- been developed. To learn more about the it work. HPHT, he says. lation, quali? ed to 160°C, and a special behavior of the chalk, Total is planning a

Despite the challenges, operators, “It (HPHT) is a big deal to us, these caisson cooling system design for the pilot using seismic nodes on the seedbed. including BG Group, say there is a “sub- are highly technically challenging ? elds Franklin wellhead platform.

Culzean stantial yet to ? nd prize” in HPHT. we need to develop,” Guys says. But it is When Total was developing Elgin also a niche, he adds. “We had to develop Franklin, Shell was developing its nearby Another major HPHT development is

How it is done new tools for this.” Shearwater ? eld, another HPHT develop- Maersk Oil North Sea’s £3-4 billion

Total E&P UK has led the HPHT-way with Franklin was discovered in 1986 and ment. Guys says the ? rms collaborated on Culzean development in central North its Elgin Franklin HPHT development in Elgin in 1991. It took 15 years and £20 a number of areas on these projects and Sea Block 22/25a. Discovered in 2008, the central North Sea. It was challenged million of research investment, before now even share a backup power supply. Culzean could be producing about 5% with pressures up to 15,500psi and tem- both could be produced. A more recent challenge on Elgin of the UK’s domestic gas needs by 2020. peratures up to 350°F. Initial development challenges Franklin was developing extended First gas is due from a new three platform

It has had a learning curve, due to the included 3-4% carbon dioxide, 30-50ppm reach wells to produce the Glenelg ? eld, installation, including a 12-slot wellhead 2012 well control incident on Elgin, but hydrogen sul? de, and a 1100psi, 190°C discovered in 1999, and developed in platform, in 88m water depth, in 2019. it is also extending the development. In temperature reservoir. There was also 175 2006, with a 7.7km-long well, at a 4km The reservoir is about 4300m below sea the fourth quarter, it is due to bring on g/l formation chlorides. Gas also had to step out. level and about 170°C, some 242km from stream two new platforms at the Elgin be delivered to the grid to speci? cation, In 2008, Total drilled its ? rst in? eld Aberdeen in the central North Sea.

Franklin complex—West Franklin and which added to the challenges. well on Franklin, which has helped Martin Rune Pedersen, managing

Elgin B—part of the development’s life To meet some of these challenges, a to extend the development’s ? eld life. director for Maersk Oil UK, says getting extension, from 22 years, as initially large well bore completion (5in, tub- Initially, the ? rm had not thought in? ll wellhead and downhole engineering anticipated, to 32 years. ing) was used to avoid local focal stress well drilling would be possible, due to right will be critical on the project, as

Philippe Guys, managing director, on production tubing. A 15,000psi pressure depletion on the ? eld. But, a well as material speci? cation.

Total E&P UK, told the Oil & Gas UK coiled tubing system was developed for well drilled in 2008 produced, “opening HPHT challenges have been recognized brie? ng that HPHT is a large proportion through tubing perforations, a produc- a new horizon,” Guys says. Technology by the UK government, which is out to of Total E&P UK’s operated reserves, tion packer was designed and quali? ed used included stress casing mud and consultation with the industry on a new totaling 54%. Some 48% of the UK’s yet for Elgin Franklin, and the company had using graphite and calcium carbonate to tax allowance. oedigital.com August 2014 | OE 49 048_OE0814_G&G2_HPHT.indd 49 7/22/14 3:14 PM

46

46

48

48