Page 50: of Offshore Engineer Magazine (Aug/Sep 2014)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2014 Offshore Engineer Magazine

Now operators can monitor, analyze and control their wells and downhole 13000 tools acoustically. 12000

Samplers

Flavio Dias joined triggered by acoustic

Halliburton in 2001 11000 as a data acquisition 10000

Pressure up annulus as specialist for testing backup to trigger samplers psig

Geology & Geophysics and subsea (TSS). In 9000

Pressure below prophase 2004, he worked

Annulus pressure 8000 overseas, developing

Pressure above prophase skills on surface well 7000

Armada N2 testing technologies. After his return to

Halliburton in 2007, Flávio worked as a 6000

Dec 29 Dec 29 Dec 29

TSS feld engineer, testing offshore 06:00 09:00 12:00 coordinator and DAS shop supervisor.

Time and date

From October 2012 to March 2014, he

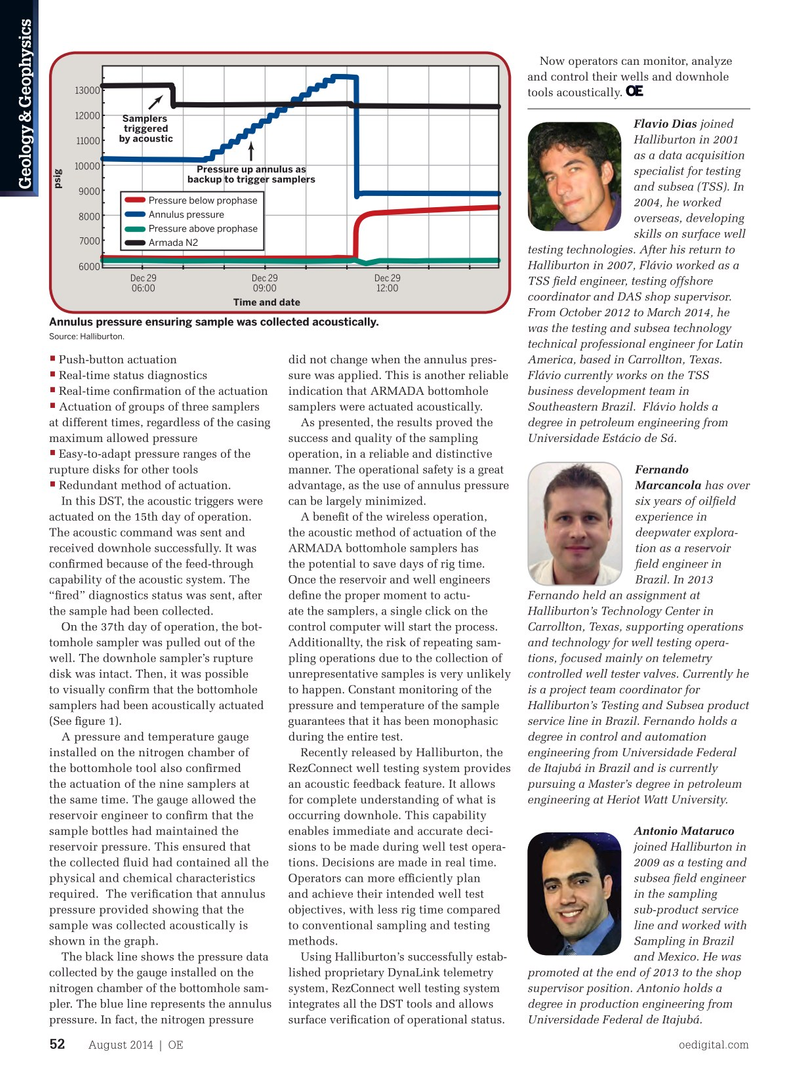

Annulus pressure ensuring sample was collected acoustically. was the testing and subsea technology

Source: Halliburton.

technical professional engineer for Latin • Push-button actuation did not change when the annulus pres- America, based in Carrollton, Texas. • Real-time status diagnostics sure was applied. This is another reliable Flávio currently works on the TSS • Real-time confrmation of the actuation indication that ARMADA bottomhole business development team in • Actuation of groups of three samplers samplers were actuated acoustically. Southeastern Brazil. Flávio holds a at different times, regardless of the casing As presented, the results proved the degree in petroleum engineering from maximum allowed pressure success and quality of the sampling Universidade Estácio de Sá.

Easy-to-adapt pressure ranges of the operation, in a reliable and distinctive • rupture disks for other tools manner. The operational safety is a great Fernando •

Redundant method of actuation. advantage, as the use of annulus pressure Marcancola has over

In this DST, the acoustic triggers were can be largely minimized. six years of oilfeld actuated on the 15th day of operation. A beneft of the wireless operation, experience in

The acoustic command was sent and the acoustic method of actuation of the deepwater explora- received downhole successfully. It was ARMADA bottomhole samplers has tion as a reservoir confrmed because of the feed-through the potential to save days of rig time. feld engineer in capability of the acoustic system. The Once the reservoir and well engineers Brazil. In 2013 “fred” diagnostics status was sent, after defne the proper moment to actu- Fernando held an assignment at the sample had been collected. ate the samplers, a single click on the Halliburton’s Technology Center in

On the 37th day of operation, the bot- control computer will start the process. Carrollton, Texas, supporting operations tomhole sampler was pulled out of the Additionallty, the risk of repeating sam- and technology for well testing opera- well. The downhole sampler’s rupture pling operations due to the collection of tions, focused mainly on telemetry disk was intact. Then, it was possible unrepresentative samples is very unlikely controlled well tester valves. Currently he to visually confrm that the bottomhole to happen. Constant monitoring of the is a project team coordinator for samplers had been acoustically actuated pressure and temperature of the sample Halliburton’s Testing and Subsea product (See fgure 1). guarantees that it has been monophasic service line in Brazil. Fernando holds a

A pressure and temperature gauge during the entire test. degree in control and automation installed on the nitrogen chamber of

Recently released by Halliburton, the engineering from Universidade Federal the bottomhole tool also confrmed

RezConnect well testing system provides de Itajubá in Brazil and is currently the actuation of the nine samplers at an acoustic feedback feature. It allows pursuing a Master’s degree in petroleum the same time. The gauge allowed the for complete understanding of what is engineering at Heriot Watt University. reservoir engineer to confrm that the occurring downhole. This capability sample bottles had maintained the enables immediate and accurate deci- Antonio Mataruco reservoir pressure. This ensured that sions to be made during well test opera- joined Halliburton in the collected fuid had contained all the tions. Decisions are made in real time. 2009 as a testing and physical and chemical characteristics

Operators can more effciently plan subsea feld engineer required. The verifcation that annulus and achieve their intended well test in the sampling pressure provided showing that the objectives, with less rig time compared sub-product service sample was collected acoustically is to conventional sampling and testing line and worked with shown in the graph. methods. Sampling in Brazil

The black line shows the pressure data Using Halliburton’s successfully estab- and Mexico. He was collected by the gauge installed on the lished proprietary DynaLink telemetry promoted at the end of 2013 to the shop nitrogen chamber of the bottomhole sam- system, RezConnect well testing system supervisor position. Antonio holds a pler. The blue line represents the annulus integrates all the DST tools and allows degree in production engineering from pressure. In fact, the nitrogen pressure surface verifcation of operational status. Universidade Federal de Itajubá.

August 2014 | OE oedigital.com 52 050_OE0814_G&G3_Halliburton.indd 52 7/22/14 3:21 PM

49

49

51

51