Page 72: of Offshore Engineer Magazine (Aug/Sep 2014)

Read this page in Pdf, Flash or Html5 edition of Aug/Sep 2014 Offshore Engineer Magazine

using instrumentation, primarily

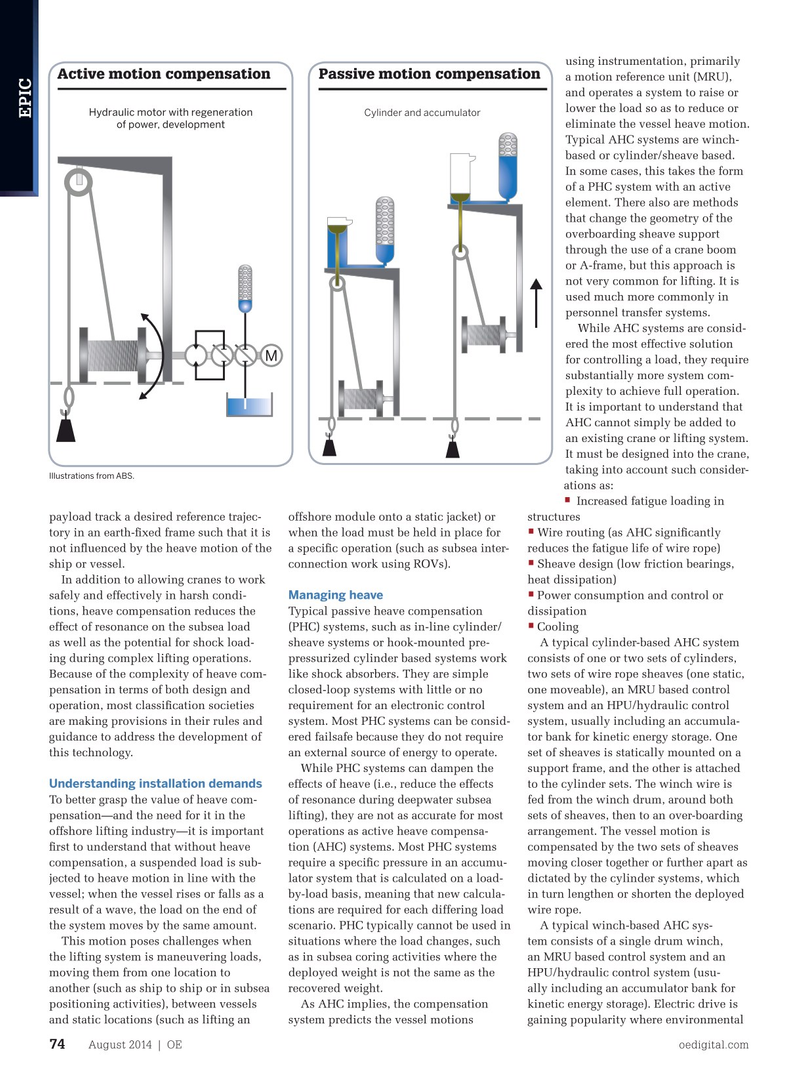

Active motion compensation Passive motion compensation a motion reference unit (MRU), and operates a system to raise or lower the load so as to reduce or

Hydraulic motor with regeneration

Cylinder and accumulator

EPIC eliminate the vessel heave motion. of power, development

Typical AHC systems are winch- based or cylinder/sheave based.

In some cases, this takes the form of a PHC system with an active element. There also are methods that change the geometry of the overboarding sheave support through the use of a crane boom or A-frame, but this approach is not very common for lifting. It is used much more commonly in personnel transfer systems.

While AHC systems are consid- ered the most effective solution

M for controlling a load, they require substantially more system com- plexity to achieve full operation.

It is important to understand that

AHC cannot simply be added to an existing crane or lifting system.

It must be designed into the crane, taking into account such consider-

Illustrations from ABS.

ations as: •

Increased fatigue loading in payload track a desired reference trajec- offshore module onto a static jacket) or structures • tory in an earth-? xed frame such that it is when the load must be held in place for Wire routing (as AHC signi? cantly not in? uenced by the heave motion of the a speci? c operation (such as subsea inter- reduces the fatigue life of wire rope) • ship or vessel. connection work using ROVs). Sheave design (low friction bearings,

In addition to allowing cranes to work heat dissipation)

Managing heave • safely and effectively in harsh condi- Power consumption and control or tions, heave compensation reduces the Typical passive heave compensation dissipation • effect of resonance on the subsea load (PHC) systems, such as in-line cylinder/ Cooling as well as the potential for shock load- sheave systems or hook-mounted pre- A typical cylinder-based AHC system ing during complex lifting operations. pressurized cylinder based systems work consists of one or two sets of cylinders,

Because of the complexity of heave com- like shock absorbers. They are simple two sets of wire rope sheaves (one static, pensation in terms of both design and closed-loop systems with little or no one moveable), an MRU based control operation, most classi? cation societies requirement for an electronic control system and an HPU/hydraulic control are making provisions in their rules and system. Most PHC systems can be consid- system, usually including an accumula- guidance to address the development of ered failsafe because they do not require tor bank for kinetic energy storage. One this technology. an external source of energy to operate. set of sheaves is statically mounted on a

While PHC systems can dampen the support frame, and the other is attached

Understanding installation demands effects of heave (i.e., reduce the effects to the cylinder sets. The winch wire is

To better grasp the value of heave com- of resonance during deepwater subsea fed from the winch drum, around both pensation—and the need for it in the lifting), they are not as accurate for most sets of sheaves, then to an over-boarding offshore lifting industry—it is important operations as active heave compensa- arrangement. The vessel motion is ? rst to understand that without heave tion (AHC) systems. Most PHC systems compensated by the two sets of sheaves compensation, a suspended load is sub- require a speci? c pressure in an accumu- moving closer together or further apart as jected to heave motion in line with the lator system that is calculated on a load- dictated by the cylinder systems, which vessel; when the vessel rises or falls as a by-load basis, meaning that new calcula- in turn lengthen or shorten the deployed result of a wave, the load on the end of tions are required for each differing load wire rope.

the system moves by the same amount. scenario. PHC typically cannot be used in A typical winch-based AHC sys-

This motion poses challenges when situations where the load changes, such tem consists of a single drum winch, the lifting system is maneuvering loads, as in subsea coring activities where the an MRU based control system and an moving them from one location to deployed weight is not the same as the HPU/hydraulic control system (usu- another (such as ship to ship or in subsea recovered weight. ally including an accumulator bank for positioning activities), between vessels As AHC implies, the compensation kinetic energy storage). Electric drive is and static locations (such as lifting an system predicts the vessel motions gaining popularity where environmental

August 2014 | OE oedigital.com 74 072_OE0814_EPIC5_ABS.indd 74 7/22/14 9:20 PM

71

71

73

73