Page 104: of Offshore Engineer Magazine (Sep/Oct 2014)

Read this page in Pdf, Flash or Html5 edition of Sep/Oct 2014 Offshore Engineer Magazine

Vessels

A new concept in ef? cient pipelay

MacKinnon Marine’s Alex the reel lay vessel waiting or making pipelay vessels.

multiple transits with short pipe stalks,

The current preferred system of pipe

Jackson discusses the merits of thus negating the ef? ciency bene? ts construction at an onshore spool base, the company’s new spiral offered.

requiring long transits of a reel lay vessel to collect the pipe, is extremely expen- Pipe construction can be carried out pre-lay system, which seeks to sive and inef? cient in terms of utilization by a very simple barge or by a purpose bring pipe construction closer of the vessel, a huge capital asset with built vessel. The barge is relatively low- to the lay site and eliminate the massive running costs. cost and the increased output which is required can be achieved by using need for a spool base.

Spiral pre-lay process a number of vessels for construction.

It can be seen that, since the reel lay s the requirement to lay pipe- The purpose built vessel, however, speed is much faster than the pipe lines in an ever-increasing is a much higher investment and its

A construction, and the time lost in transit range of distant locations con- own ef? ciency must be maximized by has been greatly reduced, there is a need tinues, there is a corresponding increase enabling it to produce a number of pipe to accelerate pipe construction to avoid in pressure to improve the utilization of stalks simultaneously. For instance, the deck arrangements can be optimized to create an ef? cient and versatile pipeline

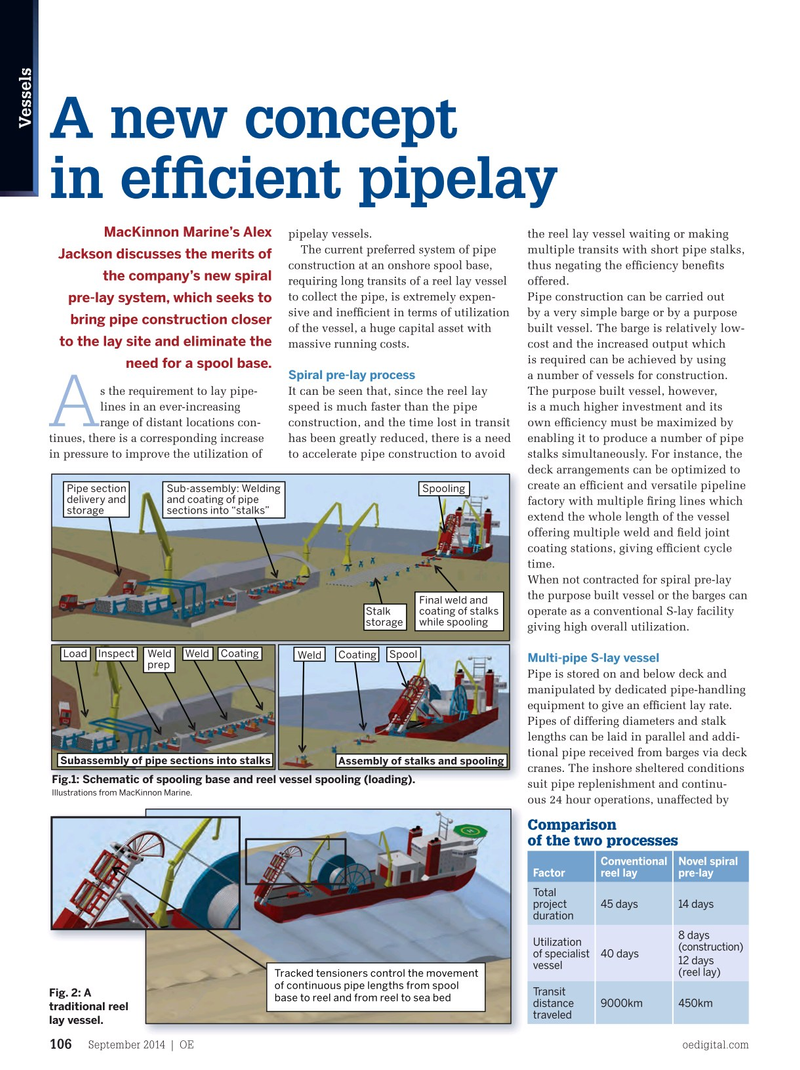

Pipe section Sub-assembly: Welding Spooling delivery and and coating of pipe factory with multiple ? ring lines which storage sections into “stalks” extend the whole length of the vessel offering multiple weld and ? eld joint coating stations, giving ef? cient cycle time.

When not contracted for spiral pre-lay the purpose built vessel or the barges can

Final weld and coating of stalks

Stalk operate as a conventional S-lay facility storage while spooling giving high overall utilization.

Weld Coating Inspect Weld Weld Coating Load Spool

Multi-pipe S-lay vessel prep

Pipe is stored on and below deck and manipulated by dedicated pipe-handling equipment to give an ef? cient lay rate.

Pipes of differing diameters and stalk lengths can be laid in parallel and addi- tional pipe received from barges via deck

Subassembly of pipe sections into stalks Assembly of stalks and spooling cranes. The inshore sheltered conditions

Fig.1: Schematic of spooling base and reel vessel spooling (loading). suit pipe replenishment and continu-

Illustrations from MacKinnon Marine.

ous 24 hour operations, unaffected by

Comparison of the two processes

Conventional Novel spiral

Factor reel lay pre-lay

Total project 45 days14 days duration 8 days

Utilization (construction) of specialist 40 days 12 days vessel (reel lay)

Tracked tensioners control the movement of continuous pipe lengths from spool

Transit

Fig. 2: A base to reel and from reel to sea bed distance 9000km450km traditional reel traveled lay vessel.

September 2014 | OE oedigital.com 106 106_OE0914_Vessels3_Spiral Lay.indd 106 8/21/14 9:18 PM 08212014212148

103

103

105

105