Page 86: of Offshore Engineer Magazine (Oct/Nov 2014)

Read this page in Pdf, Flash or Html5 edition of Oct/Nov 2014 Offshore Engineer Magazine

Automation of the pressures, because of the tempera- tures, because of where it is where you are operating.”

Add in working with different systems that must talk to one another and you need a system that can bring all the data together for engineers and operators to use for their purposes.

Efficiency “You may have a programmable logic controller (PLC) running your process

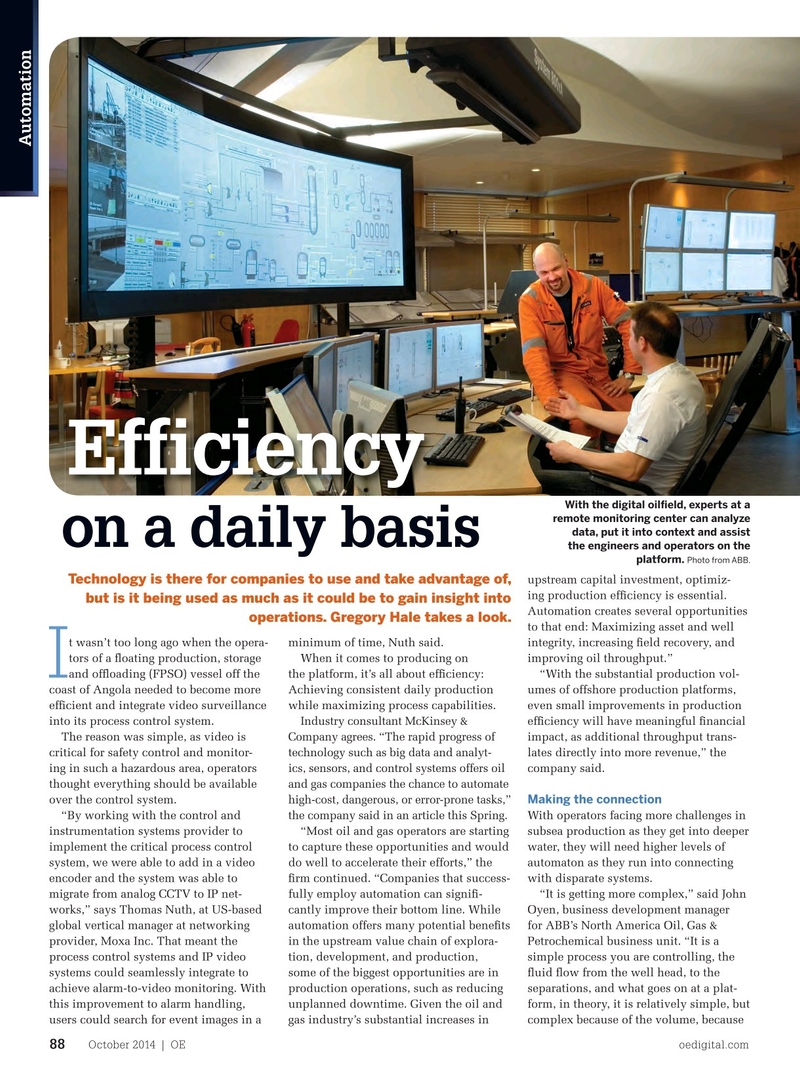

With the digital oil? eld, experts at a control, you are going to have lots of little remote monitoring center can analyze data, put it into context and assist skids that have some modular areas that on a daily basis the engineers and operators on the will have some form of a PLC,” Oyen platform.

Photo from ABB. said. “The same thing goes from the elec- upstream capital investment, optimiz- tric side. With your power generation,

Technology is there for companies to use and take advantage of, ing production ef? ciency is essential. your generator controls could be a GE, or but is it being used as much as it could be to gain insight into

Automation creates several opportunities they could be Siemens or Wartsila or a operations. Gregory Hale takes a look. to that end: Maximizing asset and well GE turbine, then you need the repository t wasn’t too long ago when the opera- minimum of time, Nuth said. integrity, increasing ? eld recovery, and for all the data related to how that plat- tors of a ? oating production, storage When it comes to producing on improving oil throughput.” form is operating from the equipment for

I and of? oading (FPSO) vessel off the the platform, it’s all about ef? ciency: “With the substantial production vol- process control. Also, you need to know coast of Angola needed to become more Achieving consistent daily production umes of offshore production platforms, the ? ows and how well your separators ef? cient and integrate video surveillance while maximizing process capabilities. even small improvements in production are running and your tank level. As we

Industry consultant McKinsey & into its process control system. ef? ciency will have meaningful ? nancial go forward, as the capabilities become

Company agrees. “The rapid progress of

The reason was simple, as video is impact, as additional throughput trans- greater and greater so do the HSE require- technology such as big data and analyt- critical for safety control and monitor- lates directly into more revenue,” the ments and compliance which used to be ics, sensors, and control systems offers oil ing in such a hazardous area, operators company said. voluntary now becomes mandatory.” and gas companies the chance to automate thought everything should be available

Making the connection Levels add up high-cost, dangerous, or error-prone tasks,” over the control system. the company said in an article this Spring. “By working with the control and With operators facing more challenges in But the layers of the levels of ef? ciency instrumentation systems provider to “Most oil and gas operators are starting subsea production as they get into deeper continue to mount as production ramps implement the critical process control to capture these opportunities and would water, they will need higher levels of up. To keep the production ? owing, there system, we were able to add in a video do well to accelerate their efforts,” the automaton as they run into connecting are reservoir management systems for the encoder and the system was able to ? rm continued. “Companies that success- with disparate systems. subsea wellheads the production side has migrate from analog CCTV to IP net- fully employ automation can signi? - “It is getting more complex,” said John to interface with via the control system.

works,” says Thomas Nuth, at US-based cantly improve their bottom line. While Oyen, business development manager So whether the control system is a global vertical manager at networking automation offers many potential bene? ts for ABB’s North America Oil, Gas & Rockwell, Emerson, Honeywell, Siemens, provider, Moxa Inc. That meant the in the upstream value chain of explora- Petrochemical business unit. “It is a Yokogawa, GE or ABB, the user also process control systems and IP video tion, development, and production, simple process you are controlling, the will contend with data from systems by systems could seamlessly integrate to some of the biggest opportunities are in ? uid ? ow from the well head, to the Schlumberger or Halliburton on what is achieve alarm-to-video monitoring. With production operations, such as reducing separations, and what goes on at a plat- going on from below the wellhead. this improvement to alarm handling, unplanned downtime. Given the oil and form, in theory, it is relatively simple, but “That becomes key when you get into users could search for event images in a gas industry’s substantial increases in complex because of the volume, because a well management system because you

October 2014 | OE oedigital.com 88 088_OE1014_Automation.indd 88 9/23/14 7:31 PM

85

85

87

87