Page 27: of Offshore Engineer Magazine (Nov/Dec 2014)

Read this page in Pdf, Flash or Html5 edition of Nov/Dec 2014 Offshore Engineer Magazine

ranging from enhanced monitoring to structural re? t.

rate can be used to predict the vessel’s condition in the future.

In turn, this allows the estimation of the likely tonnage of steel

Major challenges replacement needed to restore the structure to acceptable condi-

To extend the life of a structure, it is necessary to have in-depth tion. Overall, the assessment of the facts involves collecting knowledge of its condition. Lack of historical operating data is a and reviewing class records, weight control records, thickness challenge when assessing an asset’s viability for life extension. gauging reports, and inspection reports. Other challenges include previous damage, deteriorated pro- Once the status of the asset is known in terms of its current cess equipment, noncompliance with new regulations, a change condition and compliance with current design codes, a more in ? ag state, the potential for the asset to operate in more detailed assessment is performed. The more detailed assess- severe environments, weight issues (such as marine growth ment could include global reanalysis of the hull structural or additional equipment), and structural capacity. A lack of model, focusing on the fatigue-sensitive areas and any areas proper maintenance procedures also can contribute to gradual with substantial or excessive corrosion. deterioration. The asset undergoes non-destructive examination, during which engineers gather ultrasonic thickness measurements

Life extension readiness following appropriate classi? cation requirements. The ? nal

Structural integrity is

The life extension program evaluates life extension readiness. step in this phase is inspection of underwater structures: critical to sustaining

The approach to the program developed and employed by ABS appurtenances, moorings and tendon systems, risers, and cor- stable, reliable, and opti-

Group consists of assessing the facts and completing a prelimi- rosion protection systems are variously inspected for damage, mal performance.

Images from ABS Group.

nary assessment to reduce study uncertainties. external corrosion, cracking or other deterioration. From this

Evaluating an asset for life extension begins with obtaining information, a preliminary assessment is completed to reduce and reviewing the baseline information. The purpose of this uncertainties.

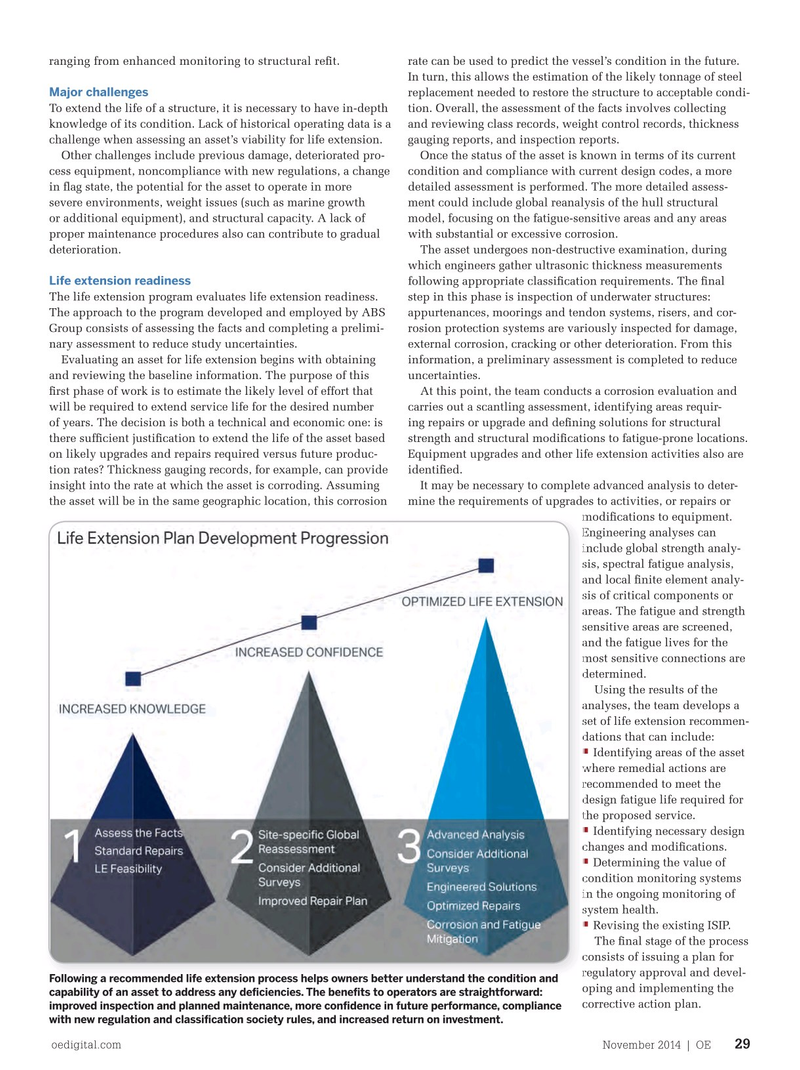

? rst phase of work is to estimate the likely level of effort that At this point, the team conducts a corrosion evaluation and will be required to extend service life for the desired number carries out a scantling assessment, identifying areas requir- of years. The decision is both a technical and economic one: is ing repairs or upgrade and de? ning solutions for structural there suf? cient justi? cation to extend the life of the asset based strength and structural modi? cations to fatigue-prone locations. on likely upgrades and repairs required versus future produc- Equipment upgrades and other life extension activities also are tion rates? Thickness gauging records, for example, can provide identi? ed.

insight into the rate at which the asset is corroding. Assuming It may be necessary to complete advanced analysis to deter- the asset will be in the same geographic location, this corrosion mine the requirements of upgrades to activities, or repairs or modi? cations to equipment. modi? cations to equipment.

Engineering analyses can Engineering analyses can include global strength analy-include global strength analy- sis, spectral fatigue analysis, sis, spectral fatigue analysis, and local ? nite element analy-and local ? nite element analy- sis of critical components or sis of critical components or areas. The fatigue and strength areas. The fatigue and strength sensitive areas are screened, sensitive areas are screened, and the fatigue lives for the and the fatigue lives for the most sensitive connections are most sensitive connections are determined. determined.

Using the results of the analyses, the team develops a analyses, the team develops a set of life extension recommen-set of life extension recommen- dations that can include:dations that can include: • •

Identifying areas of the asset where remedial actions are where remedial actions are recommended to meet the recommended to meet the design fatigue life required for design fatigue life required for the proposed service.the proposed service.

• •

Identifying necessary design changes and modi? cations.changes and modi? cations.

• •

Determining the value of condition monitoring systems condition monitoring systems in the ongoing monitoring of in the ongoing monitoring of system health.system health.

• •

Revising the existing ISIP.

The ? nal stage of the process consists of issuing a plan for consists of issuing a plan for regulatory approval and devel-regulatory approval and devel-

Following a recommended life extension process helps owners better understand the condition and oping and implementing the capability of an asset to address any de? ciencies. The bene? ts to operators are straightforward: corrective action plan. improved inspection and planned maintenance, more con? dence in future performance, compliance with new regulation and classi? cation society rules, and increased return on investment.

oedigital.com November 2014 | OE 29 028_OE1114_Asset2.indd 29 10/20/14 10:09 PM

26

26

28

28