Page 52: of Offshore Engineer Magazine (Nov/Dec 2014)

Read this page in Pdf, Flash or Html5 edition of Nov/Dec 2014 Offshore Engineer Magazine

production from that depth. As a piece of a multi-billion dollar investment, it is imperative to utilize proven technology.

“Everything on the system is a utiliza-

Subsea tion of existing technology to handle the

Reaching 20K higher pressure,” says Anthony Spinler, product manager for GE Oil & Gas. “We brought in technologies from other parts

GE’s new 20,000psi-rated BOP recently secured a contract with Maersk Drilling as part of of GE and advanced the ones we already

BP’s own Project 20K program. Jerry Lee reports on the new BOP and its control system.

have to meet the higher pressure, and to make the risk level of the new system as industry players, low as possible. The best way to man-

Maersk Drilling was age technology is to not invent too many selected to help things.” develop the Project

The primary advances are with the 20K drilling unit. In pressure maintaining components. As a the scope of a drilling safety and control mechanism, the BOP contractor package, must be able to shear the pipe and cas- there is a match in ing strings completely. This means the terms of technology, hydraulic cylinders must provide enough people, and safety and force to the rams to operate properly, yet management systems, still not damage the BOP. The additional says Frederik Smidth, wellbore pressure at 20,000psi applies chief technical offcer additional force these cylinders must

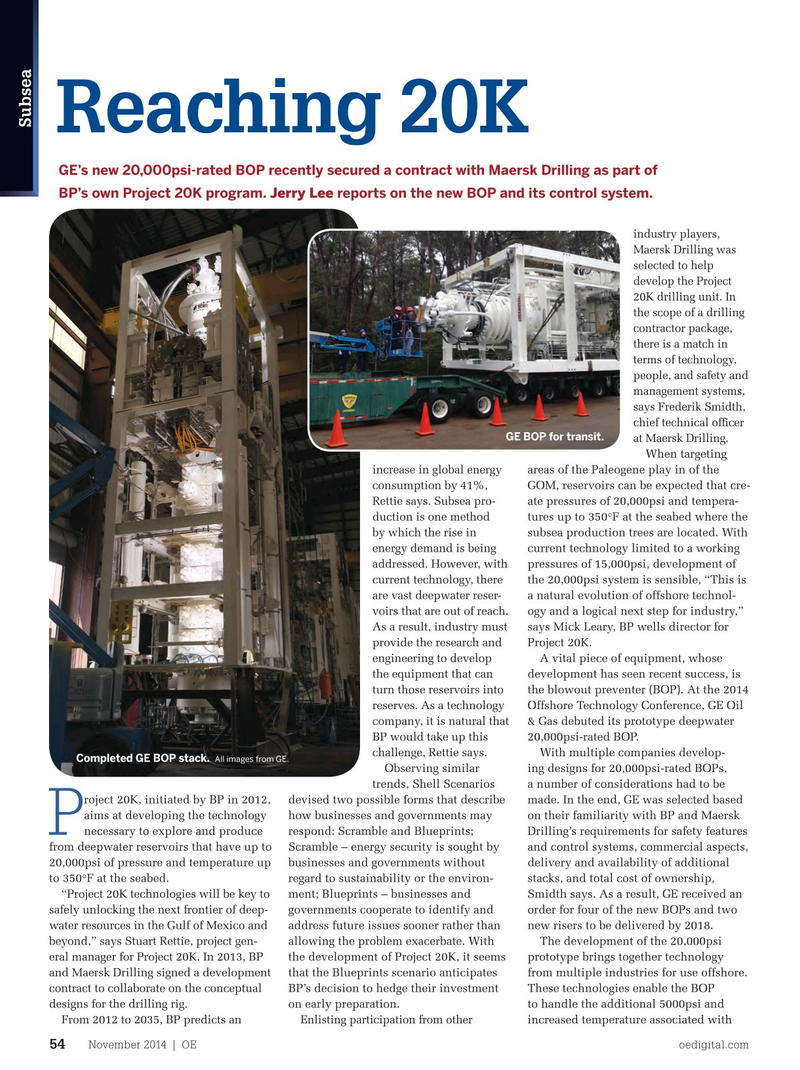

GE BOP for transit. at Maersk Drilling.

overcome before they can cut pipe or cas-

When targeting ing. Thus the working conditions neces- areas of the Paleogene play in of the increase in global energy sitated an upgrade to the body, bonnet,

GOM, reservoirs can be expected that cre- consumption by 41%, and hydraulic cylinders on the prototype. ate pressures of 20,000psi and tempera- Rettie says. Subsea pro- These components are made bigger to tures up to 350°F at the seabed where the duction is one method handle more pressure, and that keeps the subsea production trees are located. With by which the rise in risk down in the industry, Spinler says.

However, the task of producing from a energy demand is being current technology limited to a working deepwater well is not accomplished by addressed. However, with pressures of 15,000psi, development of simply making things bigger. Being so far current technology, there the 20,000psi system is sensible, “This is removed from the well head, engineers had are vast deepwater reser- a natural evolution of offshore technol- to come up with a model that allows opera- voirs that are out of reach. ogy and a logical next step for industry,” tions to be more effcient in order to make

As a result, industry must says Mick Leary, BP wells director for producing deepwater felds economic. One provide the research and Project 20K. method of improving effciency is in inno- engineering to develop A vital piece of equipment, whose vating the BOP control systems.

the equipment that can development has seen recent success, is

One ineffciency can be equipment turn those reservoirs into the blowout preventer (BOP). At the 2014 breakdown. When equipment breaks on a reserves. As a technology Offshore Technology Conference, GE Oil rig, operation must be shut down, and the company, it is natural that & Gas debuted its prototype deepwater broken equipment must be removed and

BP would take up this 20,000psi-rated BOP. replaced, resulting in non-productive time challenge, Rettie says. With multiple companies develop-

Completed GE BOP stack. All images from GE.

(NPT) which costs the company money.

Observing similar ing designs for 20,000psi-rated BOPs,

In deepwater subsea wells, NPT is com- trends, Shell Scenarios a number of considerations had to be roject 20K, initiated by BP in 2012, devised two possible forms that describe made. In the end, GE was selected based pounded simply by the logistics of the aims at developing the technology how businesses and governments may on their familiarity with BP and Maersk operation; what may take an a few hours

P to replace on a normal rig can take days in necessary to explore and produce respond: Scramble and Blueprints; Drilling’s requirements for safety features from deepwater reservoirs that have up to Scramble – energy security is sought by and control systems, commercial aspects, subsea well, all the while costing the com- pany money as well as making no progress. 20,000psi of pressure and temperature up businesses and governments without delivery and availability of additional to 350°F at the seabed. regard to sustainability or the environ- stacks, and total cost of ownership,

To mitigate NPT, the BOPs are designed to incorporate RamTel Plus sensors. Located “Project 20K technologies will be key to ment; Blueprints – businesses and Smidth says. As a result, GE received an inside the operator shaft, the sensor sends safely unlocking the next frontier of deep- governments cooperate to identify and order for four of the new BOPs and two information regarding the ram position water resources in the Gulf of Mexico and address future issues sooner rather than new risers to be delivered by 2018. and exact pressure readings in the cylin- beyond,” says Stuart Rettie, project gen- allowing the problem exacerbate. With The development of the 20,000psi der, allowing engineers to manage drilling eral manager for Project 20K. In 2013, BP the development of Project 20K, it seems prototype brings together technology operations and make real-time decisions on and Maersk Drilling signed a development that the Blueprints scenario anticipates from multiple industries for use offshore. the health of the BOP operator. contract to collaborate on the conceptual BP’s decision to hedge their investment These technologies enable the BOP to handle the additional 5000psi and on early preparation. designs for the drilling rig. To capitalize on the increasing amounts

Enlisting participation from other increased temperature associated with From 2012 to 2035, BP predicts an of data coming from sources like the

November 2014 | OE oedigital.com 54 000_OE1114_Subsea1_Jerry.indd 54 10/21/14 5:52 PM

51

51

53

53