Page 38: of Offshore Engineer Magazine (Feb/Mar 2015)

Read this page in Pdf, Flash or Html5 edition of Feb/Mar 2015 Offshore Engineer Magazine

months and see something by 6m – “a huge engineering different,” says Hand. “This accomplishment at the time.” asset has been producing for

Protective walls were also 40 years and there has been installed to protect the Ekofsk a lot of change and evolution tank against the ocean. going on. The repeat surveys

Drilling difculties helped us see better in the

Drilling is also a big chal- reservoir, under some areas

Geology & Geophysics lenge in these conditions. that were obscured areas. “As we drill through the res-

But also it is very important ervoir we also see huge pres- to understand where the sure variations,” says Hand. saturation changes and try- ing to map where that water “[While] drilling a horizon- front is going, not only from tal well, we maybe drilling a reservoir management through a water swept region stand point but also from and we will hit the water a containment standpoint front and see a 1500-2000 and also when drilling new psi pressure drop from one wells.” side of the water front to the other side over the course of

Renewal a couple of 100ft. Trying to manage that through drilling Ekofsk has not just been is very diffcult.” evolving, the Greater

The changing reservoir Ekofsk area has been going

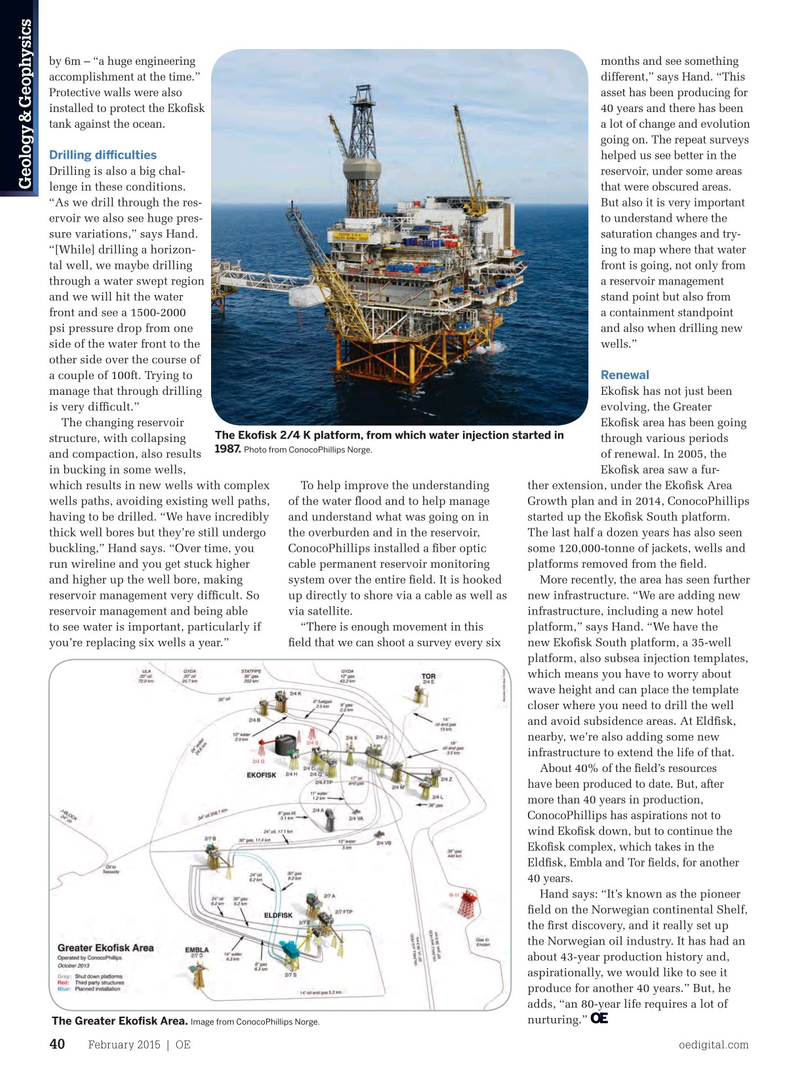

The Ekofsk 2/4 K platform, from which water injection started in structure, with collapsing through various periods 1987. Photo from ConocoPhillips Norge.

and compaction, also results of renewal. In 2005, the in bucking in some wells, Ekofsk area saw a fur- which results in new wells with complex To help improve the understanding ther extension, under the Ekofsk Area wells paths, avoiding existing well paths, of the water food and to help manage Growth plan and in 2014, ConocoPhillips having to be drilled. “We have incredibly and understand what was going on in started up the Ekofsk South platform. thick well bores but they’re still undergo the overburden and in the reservoir, The last half a dozen years has also seen buckling,” Hand says. “Over time, you ConocoPhillips installed a fber optic some 120,000-tonne of jackets, wells and run wireline and you get stuck higher cable permanent reservoir monitoring platforms removed from the feld. and higher up the well bore, making system over the entire feld. It is hooked More recently, the area has seen further reservoir management very diffcult. So up directly to shore via a cable as well as new infrastructure. “We are adding new reservoir management and being able via satellite. infrastructure, including a new hotel “There is enough movement in this to see water is important, particularly if platform,” says Hand. “We have the feld that we can shoot a survey every six you’re replacing six wells a year.” new Ekofsk South platform, a 35-well platform, also subsea injection templates, which means you have to worry about wave height and can place the template closer where you need to drill the well and avoid subsidence areas. At Eldfsk, nearby, we’re also adding some new infrastructure to extend the life of that.

About 40% of the feld’s resources have been produced to date. But, after more than 40 years in production,

ConocoPhillips has aspirations not to wind Ekofsk down, but to continue the

Ekofsk complex, which takes in the

Eldfsk, Embla and Tor felds, for another 40 years.

Hand says: “It’s known as the pioneer feld on the Norwegian continental Shelf, the frst discovery, and it really set up the Norwegian oil industry. It has had an about 43-year production history and, aspirationally, we would like to see it produce for another 40 years.” But, he adds, “an 80-year life requires a lot of nurturing.” The Greater Ekofsk Area.

Image from ConocoPhillips Norge.

February 2015 | OE oedigital.com 40 038_OE2015_G&G2_Ekofisk.indd 40 1/20/15 6:19 PM

37

37

39

39