Page 47: of Offshore Engineer Magazine (Feb/Mar 2015)

Read this page in Pdf, Flash or Html5 edition of Feb/Mar 2015 Offshore Engineer Magazine

accuracy is degraded above that dis- module separation scope to a useful level traditional surveys using instruments

EPIC tance. However, during processing, the of detail if they had to rely on existing known as Total Stations, for smaller jobs

ODL dimensional control survey (DCS) drawings and documentation. Additional such as closing spools, where speed is of team flters out all scan data beyond offshore survey trips were not an option, the essence, and for replacement of like- 15m, improving the accuracy, reducing due to a drilling campaign underway on for-like items. For surveying larger vol- the amount of data to be processed, and the platform. umes, or complex pipe-runs over several removing returns from distant spools or decks, laser scanning is a more effcient

Further benefts modules that would show up as noise. and effective method.

The digital photographic imagery is 3D scan data can also be crucial for

Future processed using PTGUI software, which brownfeld modifcations. Most platforms takes 30 images from each survey point in the North Sea have a plant design The ability to process larger amounts of and stitches them into a single panoramic management system model, which data faster is bringing point-cloud data image. From this image, six fat images provides 3D information based on the to fabricators or operators more quickly. are created, to show the front, both sides, platform’s design drawings. Using the Hand-held scanners are becoming lighter behind, above and below the survey point-cloud data, they can then compare and more accurate, and when linked to point. their design with the as-built dimensions hand-held tablets will enable data-gather-

The colored point clouds are then on the platform, which will take into ing to be carried out in near real-time. registered, using Cyclone, to ensure the account any changes made to the original It will not be long before it will be even data from each scan properly aligns. design. more cost-effective to undertake whole-

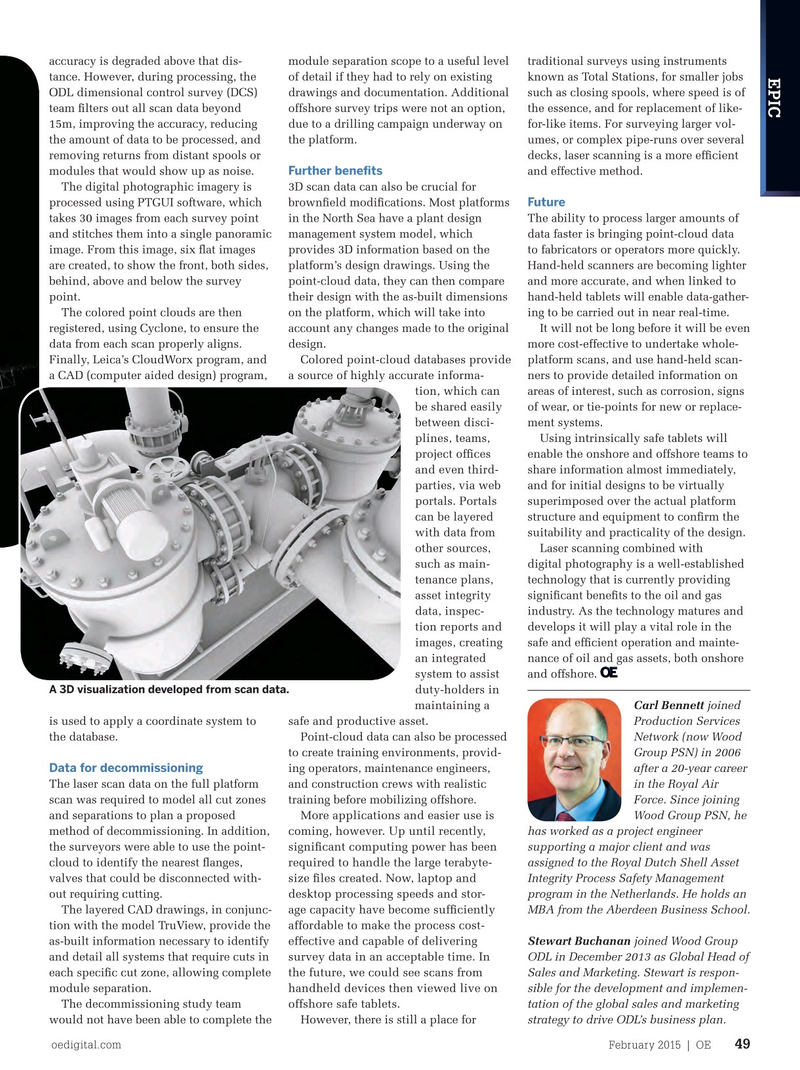

Finally, Leica’s CloudWorx program, and Colored point-cloud databases provide platform scans, and use hand-held scan- a CAD (computer aided design) program, a source of highly accurate informa- ners to provide detailed information on tion, which can areas of interest, such as corrosion, signs be shared easily of wear, or tie-points for new or replace- between disci- ment systems.

Using intrinsically safe tablets will plines, teams, enable the onshore and offshore teams to project offces share information almost immediately, and even third- and for initial designs to be virtually parties, via web superimposed over the actual platform portals. Portals structure and equipment to confrm the can be layered suitability and practicality of the design.

with data from other sources, Laser scanning combined with

Linking together data from multiple surveys to create whole platform virtual model such as main- digital photography is a well-established

Images from Wood Group ODL.

tenance plans, technology that is currently providing asset integrity signifcant benefts to the oil and gas together into a single virtual model. data, inspec- industry. As the technology matures and

Using the control network, each tion reports and develops it will play a vital role in the surveyor performs the laser scans and images, creating safe and effcient operation and mainte- panoramic color photography in locations an integrated nance of oil and gas assets, both onshore where at least fve control network targets system to assist and offshore.

A 3D visualization developed from scan data.

can be seen by the laser scanner. duty-holders in

Leica HDS6200 instruments are cur- maintaining a Carl Bennett joined rently used, with Nikon digital SLR cam- is used to apply a coordinate system to safe and productive asset. Production Services eras ftted with fsh-eye lenses capturing the database. Point-cloud data can also be processed Network (now Wood color images, and a Nodal Ninja to ensure to create training environments, provid- Group PSN) in 2006

Data for decommissioning the camera is in the same aspect as the ing operators, maintenance engineers, after a 20-year career scanner. Each up to fve minute scan, The laser scan data on the full platform and construction crews with realistic in the Royal Air performed under ISO 9001:2008, cov- scan was required to model all cut zones training before mobilizing offshore. Force. Since joining

More applications and easier use is ers a 360 degree foor to ceiling volume and separations to plan a proposed Wood Group PSN, he coming, however. Up until recently, and collects some 50 million pixels, to method of decommissioning. In addition, has worked as a project engineer signifcant computing power has been provide measurements which will meet the surveyors were able to use the point- supporting a major client and was required to handle the large terabyte- the tolerances required by fabricators. cloud to identify the nearest fanges, assigned to the Royal Dutch Shell Asset size fles created. Now, laptop and

For a clash check within a module there valves that could be disconnected with- Integrity Process Safety Management desktop processing speeds and stor- will be 50 scans typically, and a scan of out requiring cutting. program in the Netherlands. He holds an age capacity have become suffciently a platform deck will require hundreds of The layered CAD drawings, in conjunc- MBA from the Aberdeen Business School. affordable to make the process cost- scans. tion with the model TruView, provide the effective and capable of delivering

The raw data is processed, using as-built information necessary to identify Stewart Buchanan joined Wood Group survey data in an acceptable time. In

Leica’s Cyclone software, to create a sin- and detail all systems that require cuts in ODL in December 2013 as Global Head of the future, we could see scans from gle point cloud; a 3D display of the laser each specifc cut zone, allowing complete Sales and Marketing. Stewart is respon- handheld devices then viewed live on returns from the scanner in one posi- module separation. sible for the development and implemen- offshore safe tablets. tion. The scanner is designed to ignore The decommissioning study team tation of the global sales and marketing signals returned from beyond 80m, as the would not have been able to complete the However, there is still a place for strategy to drive ODL’s business plan.

oedigital.com February 2015 | OE 49 048_OE2015_EPIC1_Wood.indd 49 1/20/15 6:30 PM

46

46

48

48