Page 40: of Offshore Engineer Magazine (Apr/May 2015)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2015 Offshore Engineer Magazine

Drilling

Infow control distribution in a completed well sys-

Reservoir engineers are getting to grips with automatic fow tem. The model is validated by com- control devices to limit water cut and gas breakthrough – just paring results obtained with extensive testing in a multiphase fow loop and as they did with their passive forbearers, explain Benn A Voll, actual feld examples following the

Ismarullizam Mohd Ismail, and Iko Oguche.

installation of more than 10,000 of the company’s AICDs in more ne of the limiting than 50 wells globally.

Results from Linear Regression Results factors affecting the from Multi-Variable Non-Linear Regression

AICD benefts

O length of horizon-

One type of AICD available in tal wells has been the effec-

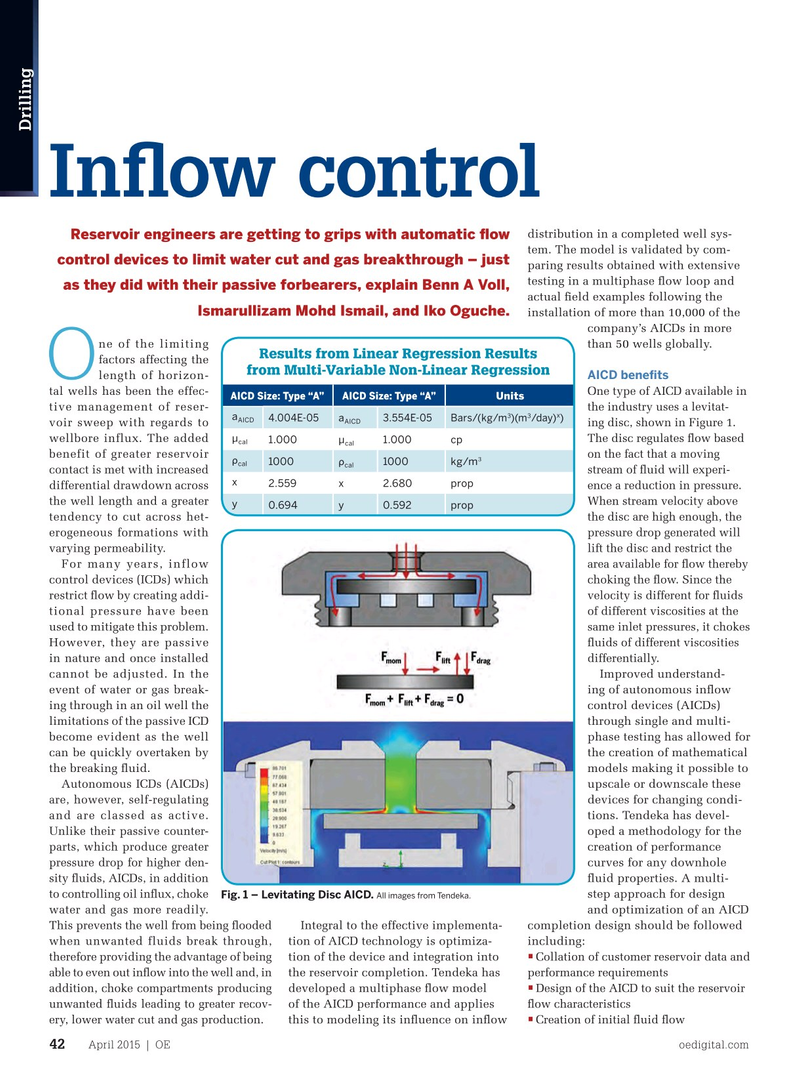

AICD Size: Type “A”AICD Size: Type “A” Units the industry uses a levitat- tive management of reser- x 3 3 a a 4.004E-05 3.554E-05 Bars/(kg/m )(m /day) )

AICD

AICD ing disc, shown in Figure 1. voir sweep with regards to µ

The disc regulates fow based wellbore influx. The added 1.000 µ 1.000 cp cal cal benefit of greater reservoir on the fact that a moving 3 ?

1000 ? 1000 kg/m cal cal contact is met with increased stream of fuid will experi- x 2.559 x 2.680 prop differential drawdown across ence a reduction in pressure. the well length and a greater

When stream velocity above y 0.694 y 0.592 prop tendency to cut across het- the disc are high enough, the erogeneous formations with pressure drop generated will varying permeability.

lift the disc and restrict the

For many years, inflow area available for fow thereby control devices (ICDs) which choking the fow. Since the restrict fow by creating addi- velocity is different for fuids tional pressure have been of different viscosities at the used to mitigate this problem. same inlet pressures, it chokes

However, they are passive fuids of different viscosities in nature and once installed differentially.

Improved understand- cannot be adjusted. In the ing of autonomous infow event of water or gas break- control devices (AICDs) ing through in an oil well the through single and multi- limitations of the passive ICD become evident as the well phase testing has allowed for can be quickly overtaken by the creation of mathematical models making it possible to the breaking fuid.

Autonomous ICDs (AICDs) upscale or downscale these are, however, self-regulating devices for changing condi- and are classed as active. tions. Tendeka has devel-

Unlike their passive counter- oped a methodology for the parts, which produce greater creation of performance curves for any downhole pressure drop for higher den- fuid properties. A multi- sity fuids, AICDs, in addition step approach for design to controlling oil infux, choke

Fig. 1 – Levitating Disc AICD. All images from Tendeka.

and optimization of an AICD water and gas more readily.

Integral to the effective implementa- completion design should be followed

This prevents the well from being fooded tion of AICD technology is optimiza- including: when unwanted fluids break through, • tion of the device and integration into therefore providing the advantage of being Collation of customer reservoir data and the reservoir completion. Tendeka has able to even out infow into the well and, in performance requirements • developed a multiphase fow model addition, choke compartments producing Design of the AICD to suit the reservoir of the AICD performance and applies unwanted fuids leading to greater recov- fow characteristics • this to modeling its infuence on infow ery, lower water cut and gas production. Creation of initial fuid fow

April 2015 | OE oedigital.com 42 042_OE0415_D&C1_Tendeka.indd 42 3/24/15 12:45 PM

39

39

41

41