Page 44: of Offshore Engineer Magazine (Apr/May 2015)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2015 Offshore Engineer Magazine

EPIC

The harsh reality

Photo by Robert Callaway for materials depends on effec-

Wood Group Kenny’s tive IM to reach an

Luis F. Gar? as outlines extended service life, the challenges relating but IM and materials engineering should to material selection and be done during testing for eventual use in the design phase. harsh environments.

It should consider the environmental he increasingly extreme environ- interaction of the ments faced in oil and gas pro- materials during the

T duction are posing more demand quali? cation of the on the materials that comprise the vital new technologies

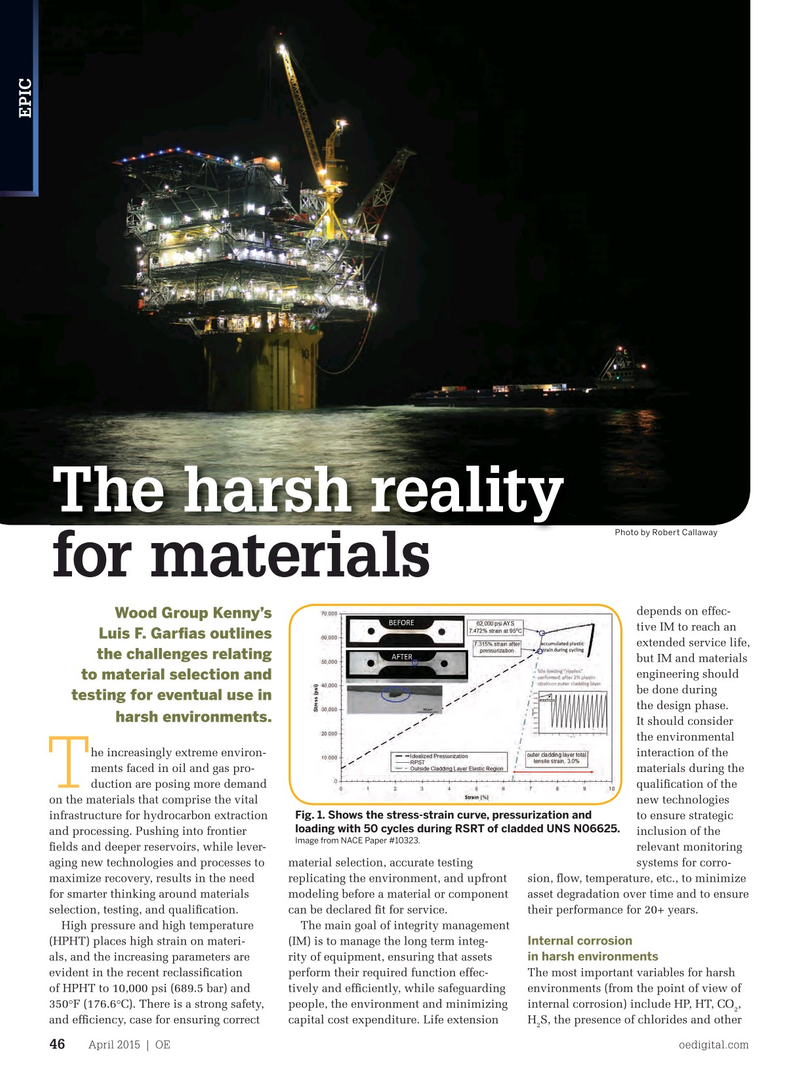

Fig. 1. Shows the stress-strain curve, pressurization and infrastructure for hydrocarbon extraction to ensure strategic loading with 50 cycles during RSRT of cladded UNS N06625.

and processing. Pushing into frontier inclusion of the

Image from NACE Paper #10323.

? elds and deeper reservoirs, while lever- relevant monitoring aging new technologies and processes to material selection, accurate testing systems for corro- maximize recovery, results in the need replicating the environment, and upfront sion, ? ow, temperature, etc., to minimize for smarter thinking around materials modeling before a material or component asset degradation over time and to ensure selection, testing, and quali? cation. can be declared ? t for service. their performance for 20+ years.

High pressure and high temperature The main goal of integrity management

Internal corrosion (HPHT) places high strain on materi- (IM) is to manage the long term integ- in harsh environments als, and the increasing parameters are rity of equipment, ensuring that assets evident in the recent reclassi? cation perform their required function effec- The most important variables for harsh of HPHT to 10,000 psi (689.5 bar) and tively and ef? ciently, while safeguarding environments (from the point of view of 350°F (176.6°C). There is a strong safety, people, the environment and minimizing internal corrosion) include HP, HT, CO , 2 and ef? ciency, case for ensuring correct capital cost expenditure. Life extension H S, the presence of chlorides and other 2

April 2015 | OE oedigital.com 46 046_0415OE_EPIC1_Woodgroup.indd 46 3/23/15 4:21 PM

43

43

45

45