Page 58: of Offshore Engineer Magazine (Apr/May 2015)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2015 Offshore Engineer Magazine

and able to be rented on a project-by- project basis.

There are a few different design and construction philosophies amongst the various manufacturers of this type of

Pipelines buoyancy, but for the canopy itself most of the recognized manufacturers will be using a Trevira-type panama-weave base cloth for maximum durability, which is then coated with a marine-resistant PVC.

Strops and connectors ftted to such bags should all comply with the 7:1 Factor of

Safety as per IMCA D-016 guidelines.

How air works

Unique Seafex, a Unique Group com- pany, manufactures infatable buoyancy which behaves according to the principle of Boyle’s Law. This dictates that as the bags are lowered deeper into the water they decrease in capacity, because the air inside gets compressed and occu- pies less volume (the reverse applies in

Allseas’ Tog Mor fat-bottom, anchored barge used for pipelaying on Wheatstone. applications where bags are being used to

Photo from Allseas.

dynamically lift from seabed to surface – from the surface and for which parachute-style bags rather than the ability to control enclosed bags are typically preferred, as the amount of buoy- the excess air generated during ascent can ancy at the moment it vent freely from their open undersides).

is required. While this effect can require topping

Surface venting is up the infatable buoys from the surface • possible at the end on their way to touchdown, this is a rela- of the process, to tively minor inconvenience given that increase safety by workboats will normally be patrolling in releasing defated the vicinity.

units under zero load. In some cases, loss of buoyancy

You can, roughly, becomes part of the engineering solution. • expect to ft about On a project currently in bid phase by 40-50-ton of solid steel Seafex, 138 x 2-ton bags were recom- or plastic buoyancy mended to be ftted to a 16in. gas pipe- capacity into a 40ft line on a barge positioned in less than

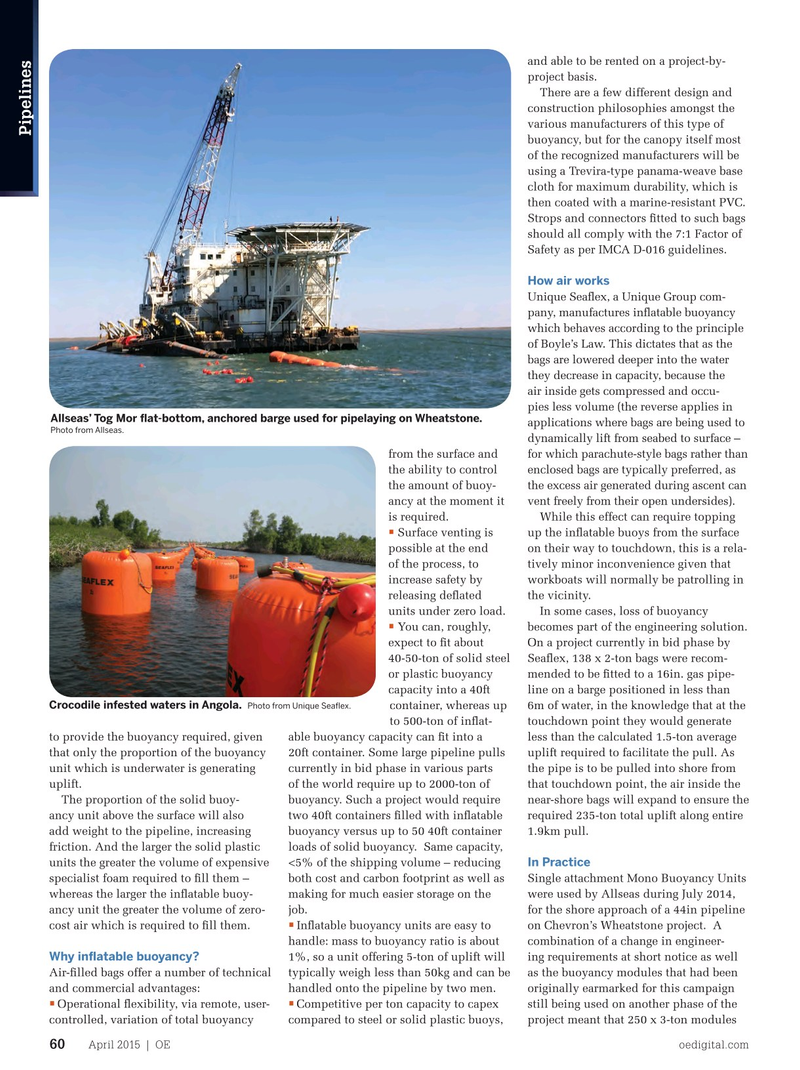

Photo from Unique Seafex.

Crocodile infested waters in Angola. container, whereas up 6m of water, in the knowledge that at the to 500-ton of infat- touchdown point they would generate to provide the buoyancy required, given able buoyancy capacity can ft into a less than the calculated 1.5-ton average that only the proportion of the buoyancy 20ft container. Some large pipeline pulls uplift required to facilitate the pull. As unit which is underwater is generating currently in bid phase in various parts the pipe is to be pulled into shore from uplift. of the world require up to 2000-ton of that touchdown point, the air inside the

The proportion of the solid buoy- buoyancy. Such a project would require near-shore bags will expand to ensure the ancy unit above the surface will also two 40ft containers flled with infatable required 235-ton total uplift along entire add weight to the pipeline, increasing buoyancy versus up to 50 40ft container 1.9km pull.

friction. And the larger the solid plastic loads of solid buoyancy. Same capacity,

In Practice units the greater the volume of expensive <5% of the shipping volume – reducing specialist foam required to fll them – both cost and carbon footprint as well as Single attachment Mono Buoyancy Units whereas the larger the infatable buoy- making for much easier storage on the were used by Allseas during July 2014, ancy unit the greater the volume of zero- job. for the shore approach of a 44in pipeline • cost air which is required to fll them. Infatable buoyancy units are easy to on Chevron’s Wheatstone project. A handle: mass to buoyancy ratio is about combination of a change in engineer-

Why infatable buoyancy?

1%, so a unit offering 5-ton of uplift will ing requirements at short notice as well

Air-flled bags offer a number of technical typically weigh less than 50kg and can be as the buoyancy modules that had been and commercial advantages: handled onto the pipeline by two men. originally earmarked for this campaign

Operational fexibility, via remote, user- Competitive per ton capacity to capex still being used on another phase of the • • controlled, variation of total buoyancy compared to steel or solid plastic buoys, project meant that 250 x 3-ton modules

April 2015 | OE oedigital.com 60 058_OE0415_Pipelines2_Unique.indd 60 3/26/15 2:57 PM

57

57

59

59