Page 69: of Offshore Engineer Magazine (Apr/May 2015)

Read this page in Pdf, Flash or Html5 edition of Apr/May 2015 Offshore Engineer Magazine

Automation they can add value through the cloud and screwdriver on the pump and the Internet.” listen to the vibration on the

A case in point is condition monitoring screwdriver. When you are talk- and big analog data analytics that allows ing about these big pumps that for a predictive maintenance plan. cost thousands and thousands of dollars, that wasn’t a good

Monitoring Mud Pumps enough solution for them. NOV

National Oilwell Varco (NOV) is a perfect implemented a condition-based example. The oil services giant was deal- monitoring system so they can, ing with trying to solve issues with mud not only know when they have a pumps that circulate drilling ? uids. Mud problem, but be able to pinpoint pumps stabilize pressure and support the where exactly in the pump the

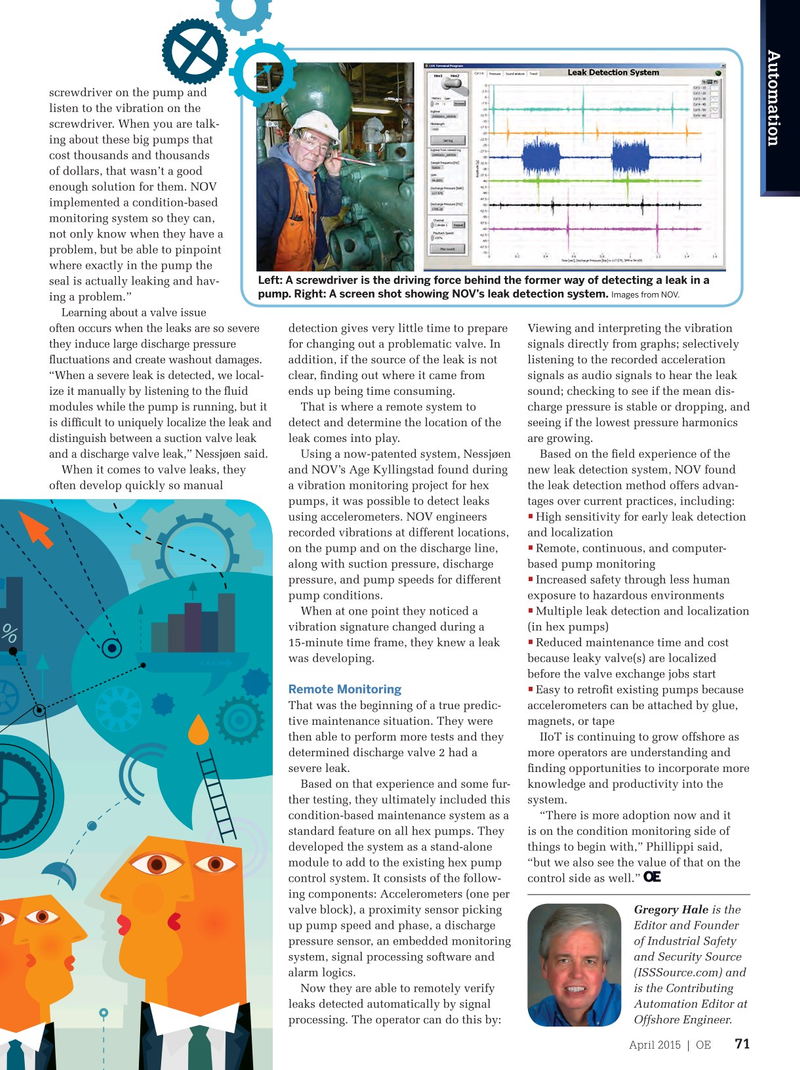

Left: A screwdriver is the driving force behind the former way of detecting a leak in a well during the drilling process and drill- seal is actually leaking and hav- pump. Right: A screen shot showing NOV’s leak detection system. Images from NOV.

ing ? uids provide friction reduction and ing a problem.”

Learning about a valve issue a means to remove cuttings. NOV created often occurs when the leaks are so severe a leak detection system for hex pumps. detection gives very little time to prepare Viewing and interpreting the vibration they induce large discharge pressure

The hex mud pump relies on six pistons, for changing out a problematic valve. In signals directly from graphs; selectively ? uctuations and create washout damages. six suction valves, and six discharge addition, if the source of the leak is not listening to the recorded acceleration “When a severe leak is detected, we local- valves. A rotating asymmetric cam drives clear, ? nding out where it came from signals as audio signals to hear the leak ize it manually by listening to the ? uid the six pistons, according to Pål Jacob ends up being time consuming. sound; checking to see if the mean dis- modules while the pump is running, but it

Nessjøen, formerly with NOV and now That is where a remote system to charge pressure is stable or dropping, and is dif? cult to uniquely localize the leak and with Kelda Drilling Controls. detect and determine the location of the seeing if the lowest pressure harmonics distinguish between a suction valve leak “Previously, they were listening leak comes into play. are growing.

and a discharge valve leak,” Nessjøen said.

to these pumps and trying to under- Using a now-patented system, Nessjøen Based on the ? eld experience of the stand if there was a leak,” Phillippi When it comes to valve leaks, they and NOV’s Age Kyllingstad found during new leak detection system, NOV found said. “Sometimes they would put a often develop quickly so manual a vibration monitoring project for hex the leak detection method offers advan- pumps, it was possible to detect leaks tages over current practices, including: • using accelerometers. NOV engineers High sensitivity for early leak detection recorded vibrations at different locations, and localization • on the pump and on the discharge line, Remote, continuous, and computer- along with suction pressure, discharge based pump monitoring • pressure, and pump speeds for different Increased safety through less human pump conditions. exposure to hazardous environments •

When at one point they noticed a Multiple leak detection and localization vibration signature changed during a (in hex pumps) • 15-minute time frame, they knew a leak Reduced maintenance time and cost was developing. because leaky valve(s) are localized before the valve exchange jobs start

Remote Monitoring •

Easy to retro? t existing pumps because

That was the beginning of a true predic- accelerometers can be attached by glue, tive maintenance situation. They were magnets, or tape then able to perform more tests and they IIoT is continuing to grow offshore as determined discharge valve 2 had a more operators are understanding and severe leak. ? nding opportunities to incorporate more

Based on that experience and some fur- knowledge and productivity into the ther testing, they ultimately included this system.

condition-based maintenance system as a “There is more adoption now and it standard feature on all hex pumps. They is on the condition monitoring side of developed the system as a stand-alone things to begin with,” Phillippi said, module to add to the existing hex pump “but we also see the value of that on the control system. It consists of the follow- control side as well.” ing components: Accelerometers (one per valve block), a proximity sensor picking Gregory Hale is the up pump speed and phase, a discharge Editor and Founder pressure sensor, an embedded monitoring of Industrial Safety system, signal processing software and and Security Source alarm logics. (ISSSource.com) and

Now they are able to remotely verify is the Contributing leaks detected automatically by signal Automation Editor at processing. The operator can do this by: Offshore Engineer.

oedigital.com April 2015 | OE 71 070_OE0415_Automation_em1.indd 71 3/23/15 2:55 PM

68

68

70

70